Stone removing machine for roasted coffee beans

A technology of stone removal machine and coffee, applied in the field of stone removal machine, can solve the problems of complex structure of stone removal machine, inability to popularize application, low stone removal efficiency, etc., to achieve good stone removal effect, saving labor cost and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solutions and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with specific examples. It should be understood that these descriptions are exemplary only, and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

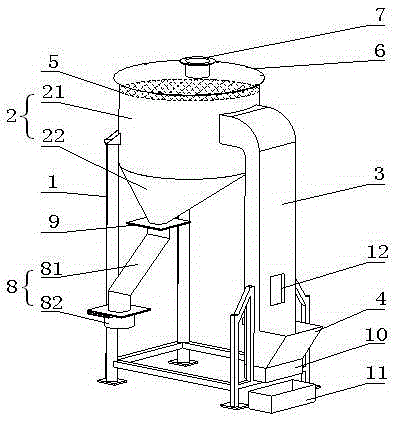

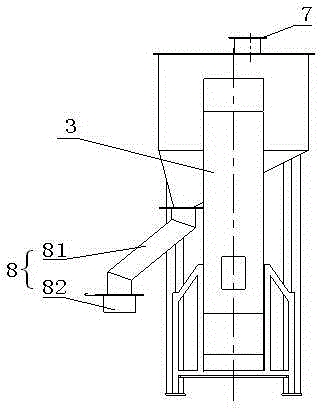

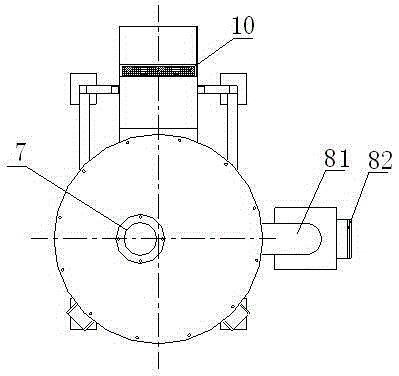

[0024] A machine for removing stones from cooked coffee beans, comprising a bracket 1, a bean cabin 2, a material pipe 3, and a hopper 4.

[0025] The bean cabin 2 is a hollow cabin fixed on the support 1 , and the bean cabin 2 includes a cylindrical cabin 21 on the upper part and an inverted cone cabin 22 on the lower part of the cylindrical cabin 21 . The upper part in the cylindrical cabin 21 is provided with a metal mesh plate 5, and the top of the cylindrical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com