Permanent magnet center-opening-type multi-roller multi-element high-gradient vibration energy-saving magnetic separator

A magnetic separator, high gradient technology, applied in high gradient magnetic separator, magnetic separation, solid separation and other directions, can solve the problems of low field strength in the separation area, high processing and manufacturing requirements, blocking magnetic media, etc. It has the advantages of convenient adjustment of vibration frequency, simple equipment processing and manufacturing, and prevention of material blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

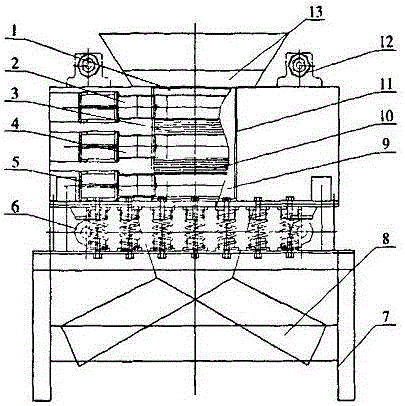

[0014] Such as figure 1 A permanent magnet split type multi-roller multi-roller high-gradient vibration energy-saving magnetic separator is shown, including: medium tank and rod medium 1, low-field permanent magnet roll 2, coarse medium mesh groove and coarse medium mesh 3, middle Strong permanent magnetic roller 4, strong permanent magnetic roller in shopping malls 5, mechanical vibrator 6, frame 7, discharge hopper 8, machine body 9, medium mesh groove and fine medium mesh 10, transparent sorting window 11, pneumatic vibrator 12, feeding Material hopper 13, damping spring 14; said body 9 is placed on the frame through said damping spring 14; the magnetic separator adopts a split symmetrical structure.

[0015] The pneumatic vibrator 12 and the mechanical vibrator 6 are respectively installed on the upper part and the lower part of the body 9 .

[0016] The upper part of the machine body has a feeding funnel 13, and a screen is set up on the neck of the funnel to remove the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com