Concentration evaporator for sodium sulfide

A technology of concentrating evaporation and alkali sulfide, applied in evaporator accessories, evaporation, chemical instruments and methods, etc., can solve the problems of inconvenient operation for workers, achieve the effect of reducing labor burden and improving evaporation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

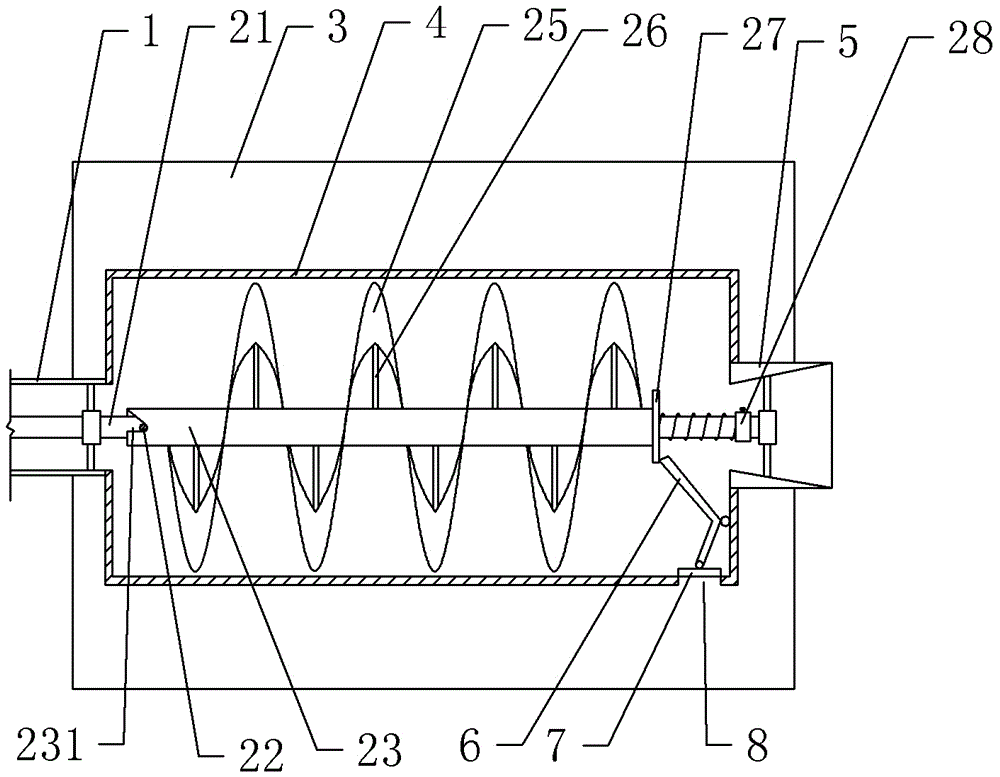

[0015] The reference signs in the drawings of the description include: the first hollow shaft 1, the heating chamber 3, the heat exchange cylinder 4, the second hollow shaft 5, the lever 6, the cover plate 7, the discharge port 8, the rotating shaft 21, the fixing pin 22, Sleeve 23, card slot 231, spiral belt 25, bracket 26, push plate 27, slide block 28.

[0016] like figure 1 The shown concentration evaporator for alkali sulfide includes a heating chamber 3 and a heat exchange cylinder 4 installed in the heating chamber 3, and the heating chamber 3 has a high-temperature gas inlet and a gas outlet. The heating chamber 3 is provided with a first driving mechanism, the first driving mechanism is a motor, and a worm gear mechanism is provided between the first driving mechanism and the heat exchange cylinder 4 . A discharge port 8 is provided on the side wall of the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com