Rear edge frame of aluminum material composite board

A rear frame and synthetic panel technology, which is applied in furniture parts, household appliances, construction, etc., can solve the problems of troublesome connection between panels, not very strong connection, and non-arbitrary structure increase, so as to achieve scientific and reasonable design and structural composition Innovative ideas and good market prospects

Inactive Publication Date: 2017-05-10

广西平果恒通铜铝门业有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] 2. The growth of the structure cannot be arbitrarily

[0010] 3. The connection

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

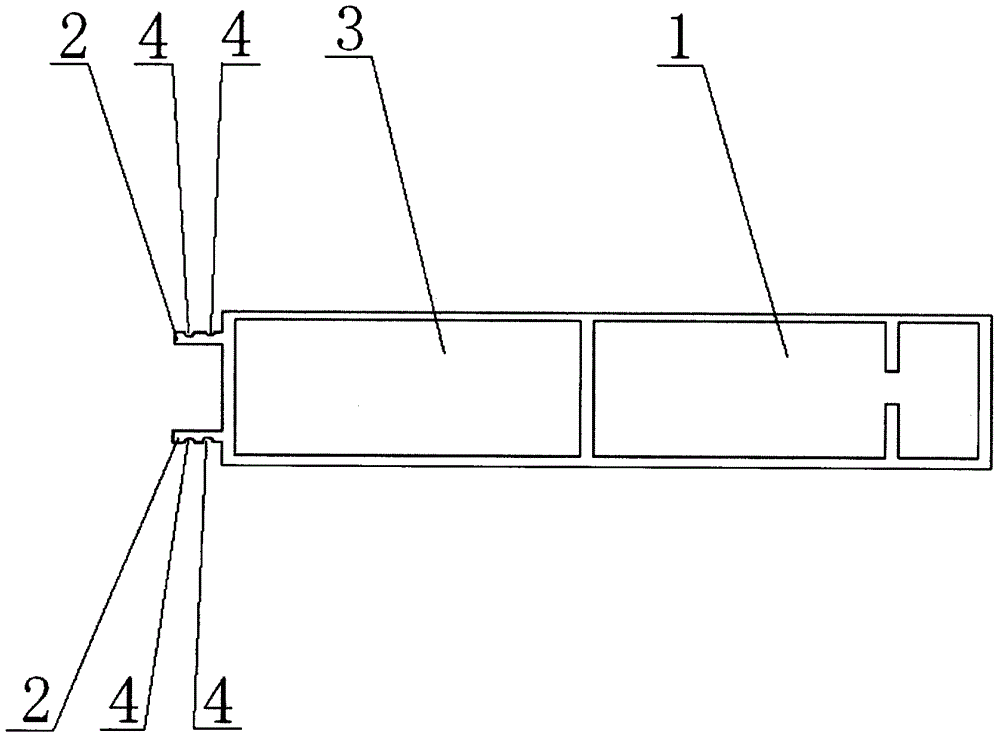

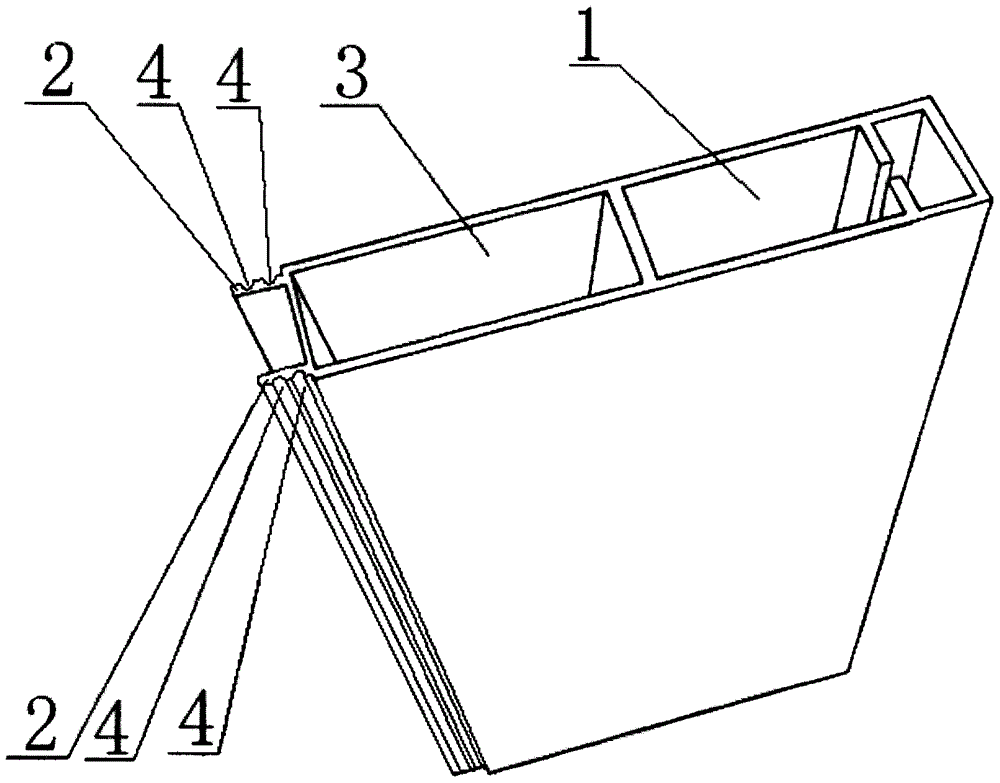

The invention discloses a rear edge frame of aluminum material composite board. Specifically, the rear edge frame is a square aluminum material panel which is hollowed out; a corner clip slot position is formed in the right end of the rear edge frame; an inner fastener position and a corner clip reserved slot position are formed in the left end of the rear edge frame; and a fastening groove is formed in the outer side of the inner fastener position. The rear edge frame provided by the invention can be combined with a front edge frame and a plurality of middle edge frames, so that the complete firm aluminum material composite board is formed. The specification and size of the composite board can be adjusted as required by increasing or decreasing the plurality of middle edge frames. The aluminum material composite board, which is combined by taking the rear edge frame provided by the invention as one of carriers, is quit strong in wear resistance, weather resistance and corrosion resistance, and moreover, the composite board is environment-friendly and beautiful. In addition, the aluminum material composite board can be widely applied to furniture and building decoration materials; and the aluminum material composite board has a quite good market prospect.

Description

technical field [0001] The invention belongs to a new type of board, in particular to a rear frame of an aluminum composite board. [0002] technical background [0003] At present, aluminum panels made of aluminum include aluminum veneer, aluminum-plastic composite panel and composite aluminum panel. [0004] Aluminum veneer is a kind of pure aluminum plate. The production of aluminum veneer requires large-scale equipment, resulting in high product cost and high price. [0005] The aluminum-plastic composite panel is a composite material processed on special aluminum-plastic panel production equipment with chemically treated coated aluminum plate as the surface material and polyethylene plastic as the core material. The unique performance of the aluminum-plastic composite panel itself determines its wide range of uses: it can be used for building exterior walls, curtain wall panels, renovation of old buildings, interior wall and ceiling decoration, advertising signs, displa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A47B96/00A47B96/20E04F13/072

CPCA47B96/00A47B96/201E04F13/072

Inventor 邓永成

Owner 广西平果恒通铜铝门业有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com