Ready-to-eat pig trotters, pig trotter degreasing process and pig trotter processing technology including pig trotter degreasing process

A degreasing process and processing technology, which is applied in the field of food processing, can solve problems such as greasy taste, inability to accurately control the amount of degreasing, and incomplete degreasing, and achieve the effect of strong fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment one: a kind of trotter degreasing process, comprises the following steps:

[0038] Step 1: lipase cultivation: take the lipase and place it in water, adjust the pH value to 5-7, expand the cultivation and set aside;

[0039] Step 2: Degreasing trotters: Take edible alkali and water, add edible salt, add the cultured lipase in step 1 after heating up, then add trotters, heat up after heat preservation to inactivate enzymes, detect enzyme activity, and wait until there is no enzyme activity Finally, the impurities on the water surface are removed to obtain the degreased trotters.

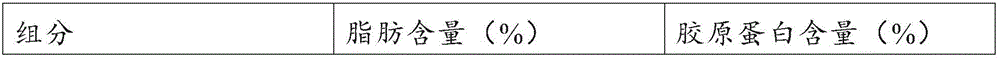

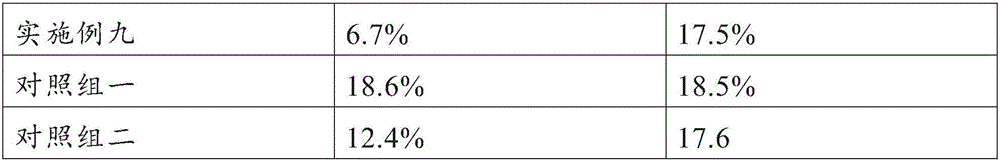

[0040]The pig's trotters after degreasing treatment in Example 1 are used as the test group, the commercially available pig's trotters are used as the control group 1, and the pig's trotters obtained by the instant degreasing pig's trotters processing technology provided by the application publication number CN102228260A are used as the control group 2. The fat content and collagen ...

Embodiment 2

[0046] Embodiment two: a kind of trotter degreasing process, comprises the following steps:

[0047] Step 1: lipase cultivation: take the lipase and put it in water at 45°C, adjust the pH value to 5.5-6.5, and expand the culture for later use;

[0048] Step 2: Degreasing trotters: Take edible alkali and water with a mass ratio of 0.05:100, add edible salt, add the cultured lipase in step 1 after heating up, then add trotters, heat up after heat preservation to kill enzymes, and detect enzymes activity, after no enzymatic activity, remove impurities on the water surface to obtain degreased trotters.

[0049] For Example 2, the degreased trotters were used as the test group, the commercially available trotters were used as the control group 1, and the trotters obtained by the instant degreased trotters processing technology provided by the application publication number CN102228260A were used as the control group 2 , and the fat content and collagen content were detected respec...

Embodiment 3

[0055] Embodiment three: a kind of trotter degreasing process, comprises the following steps:

[0056] Step 1: lipase cultivation: take the lipase and place it in 40°C water, adjust the pH value to 6.0, and expand the culture for later use;

[0057] Step 2: Degreasing trotters: Take edible alkali and water with a mass ratio of 1:100, add edible salt, heat up to 40°C, and put in the lipase 10 obtained in Step 1 4 u·g -1 The unit is 150ml, and then 260kg of pig’s trotters are added. After heat preservation for 50 minutes, the temperature is raised to 100°C to inactivate the enzyme, and the enzyme activity is detected.

[0058] For Example 3, the degreased trotters were used as the test group, the commercially available trotters were used as the control group 1, and the trotters obtained by the instant degreased trotters processing technology provided by the application publication number CN102228260A were used as the control group 2 , and the fat content and collagen content w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com