Full-automatic dumpling production line

A fully automatic, production line technology, applied in the directions of baking, mixing/kneading with vertical installation tools, dough fermenter, etc., it can solve the problems of inability to meet daily needs, continuous supply of noodles, high labor costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

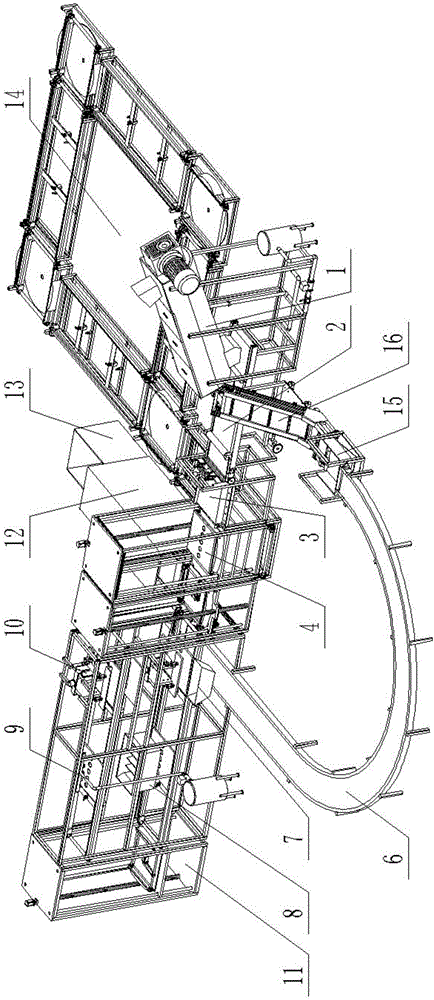

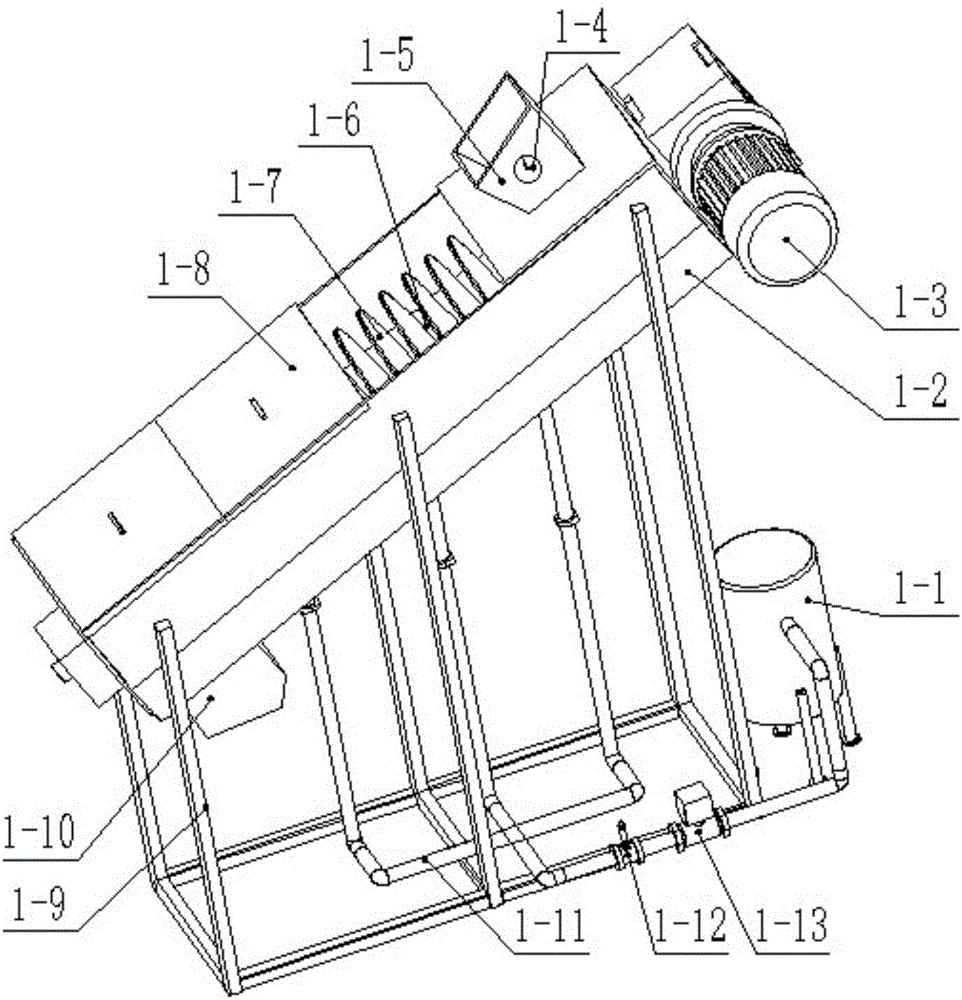

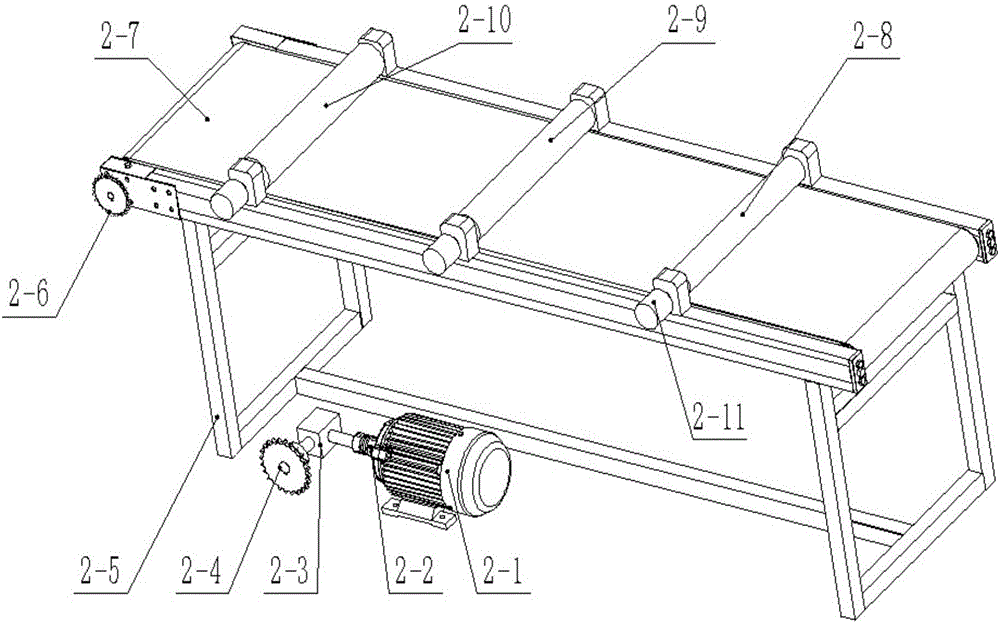

[0047] Such as figure 1 with 13 As shown, the fully automatic dumpling production line includes a dough mixing device 1, a noodle belt forming device 2, a noodle belt segmenting device 3, a transitional noodle conveying and resting device 4, a transitional collection device 5, a first chain transmission device, and an annular remaining noodle Recycling conveyor belt 6, dumpling skin forming device 7, filling device 8, second chain transmission device, dumpling skin trimming device 9, dumpling wrapping forming device 10, upper and lower conveying device 11, quick freezing device 12, material storage box 13 , wake up noodle device track 14, recovery transition device 15, climbing conveyor 16 and dumpling mold device 17. The noodle band forming device 2 is arranged at the output end of the dough kneading device 1; the noodle band forming device 3 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com