Warehouse bacteriostatic herbicide and preparation method

A herbicide and warehouse technology, applied in the directions of herbicides and algaecides, botanical equipment and methods, fungicides, etc., can solve the problem of large residues of herbicides, achieve good removal effect, prevent pollution, and inhibit mitosis. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

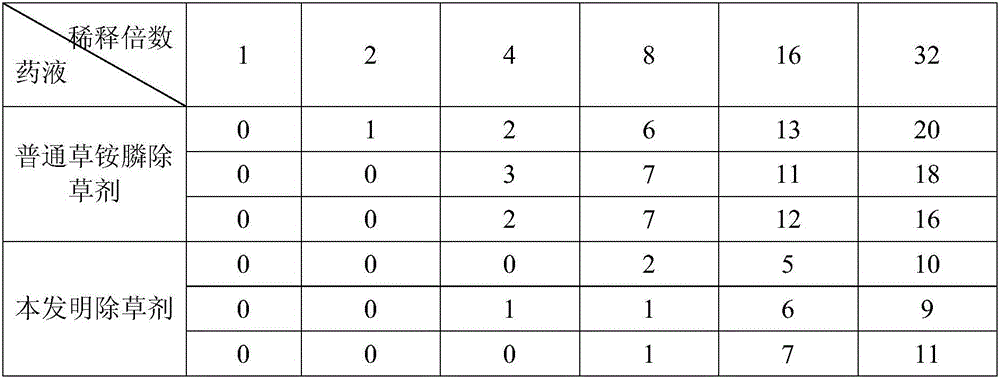

Examples

Embodiment 1

[0021] A bacteriostatic herbicide for warehouse use, characterized in that the herbicide comprises the following components in parts by mass: 10 parts of glufosinate-ammonium, 10 parts of Nuxychium chinensis extract, 1 part of Kochia chinensis extract , 0.8 parts of sorbitol polyoxyethylene ether, 0.4 parts of methyl hydroxyethyl cellulose, 0.4 parts of toluene, 1 part of silicone milk, 0.8 parts of bentonite, and 1 part of copper sulfate monohydrate.

[0022] A method for preparing a bacteriostatic herbicide for storage, the method comprising the following steps:

[0023] (1) Take by weighing glufosinate-ammonium, rhubarb extract, bentonite, copper sulfate monohydrate mixed grinding, cross 80 mesh sieve, obtain mixture;

[0024] (2) Add water to the phase mixture, the mass fraction of the water is 5 parts, stir at 50° C. for 60 minutes to make the mixture uniform, then add sorbitol polyoxyethylene ether, methyl hydroxy Ethyl cellulose, toluene, finally add silicone milk, sti...

Embodiment 2

[0026] A bacteriostatic herbicide for warehouse use, characterized in that the herbicide comprises the following components in parts by mass: 25 parts of glufosinate-ammonium, 30 parts of Nuxychnium chinensis extract, 10 parts of Kochia chinensis extract , 3.5 parts of sorbitol polyoxyethylene ether, 3 parts of methyl hydroxyethyl cellulose, 3 parts of toluene, 2 parts of silicone milk, 4 parts of bentonite, 5 parts of copper sulfate monohydrate.

[0027] A method for preparing a bacteriostatic herbicide for storage, the method comprising the following steps:

[0028] (1) Take by weighing glufosinate-ammonium, rhubarb extract, bentonite, copper sulfate monohydrate mixed grinding, cross 80 mesh sieve, obtain mixture;

[0029] (2) Add water to the phase mixture, the mass fraction of the water is 5 parts, stir at 50° C. for 60 minutes to make the mixture uniform, then add sorbitol polyoxyethylene ether, methyl hydroxy Ethyl cellulose, toluene, finally add silicone milk, stir eve...

Embodiment 3

[0031] A bacteriostatic herbicide for warehouse use, the herbicide includes the following components in parts by mass: 15 parts of glufosinate-ammonium, 15 parts of Nuxychium chinensis extract, 3 parts of Kochia chinensis extract, alkyl glycoside 1 part, 0.8 parts of ethyl hydroxyethyl cellulose, 0.8 parts of xylene, 1.2 parts of defoamer, 1.2 parts of bentonite, 2 parts of copper sulfate monohydrate.

[0032] A method for preparing a bacteriostatic herbicide for storage, the method comprising the following steps:

[0033] (1) Take by weighing glufosinate-ammonium, rhubarb extract, bentonite, copper sulfate monohydrate mixed grinding, cross 80 mesh sieve, obtain mixture;

[0034] (2) Add water to the phase mixture, the mass fraction of the water is 5 parts, stir at 50°C for 60min to make the mixture uniform, then add alkyl glucoside, ethyl hydroxyethyl cellulose to the uniformly mixed material element, xylene, and finally add phosphoric acid, and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com