A feeding trough for dairy cows

A technology for feeding troughs and cows, applied in animal feeding devices, applications, animal husbandry, etc., can solve the problem that cows cannot accurately grasp the time and quantity, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail through specific embodiments below.

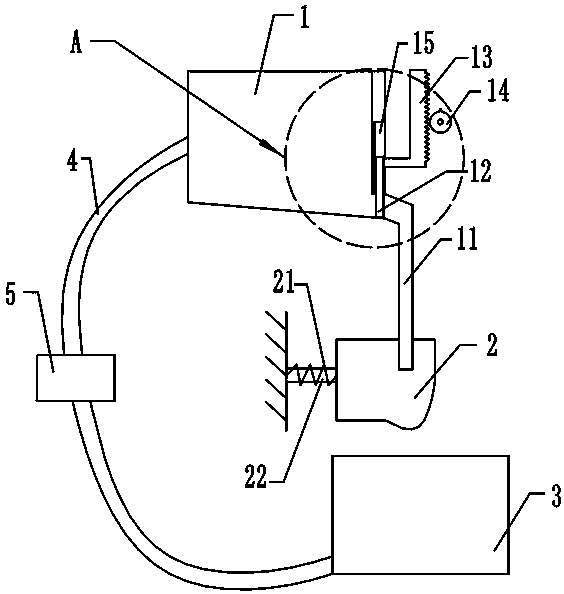

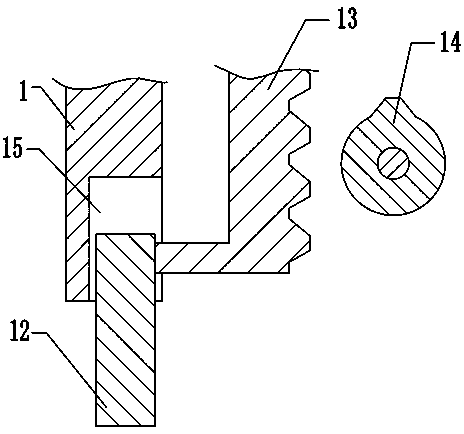

[0022] The reference signs in the accompanying drawings of the description include: material storage box 1, material collecting tank 2, feeding tank 3, air pipe 4, fan 5, feeding pipe 11, inserting plate 12, L-shaped dial 13, dial 14, slide Groove 15, torsion spring 21, pole 22.

[0023] Such as figure 1 As shown: above the feeding trough 3, a collecting tank 2 is placed, and the outer end of the collecting tank 2 is sunken downwards. One side of the collecting tank 2 is rotatably hinged on one end of the pole 22. It is 90° on both sides of the axial direction of the support rod 22, and the other end of the support rod 22 is fixed to the wall. , a material storage box 1 is placed above the material collection tank 2, and the side of the material storage box 1 close to the inclined inner bottom is provided with a discharge port. A chute 15 is provided on the wall of the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com