Dosing device

A quantitative feeding device and feeding technology, applied in transportation, packaging, loading/unloading, etc., can solve the problems of high price, high cost, complex structure, etc., and achieve the effect of simple structure and principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

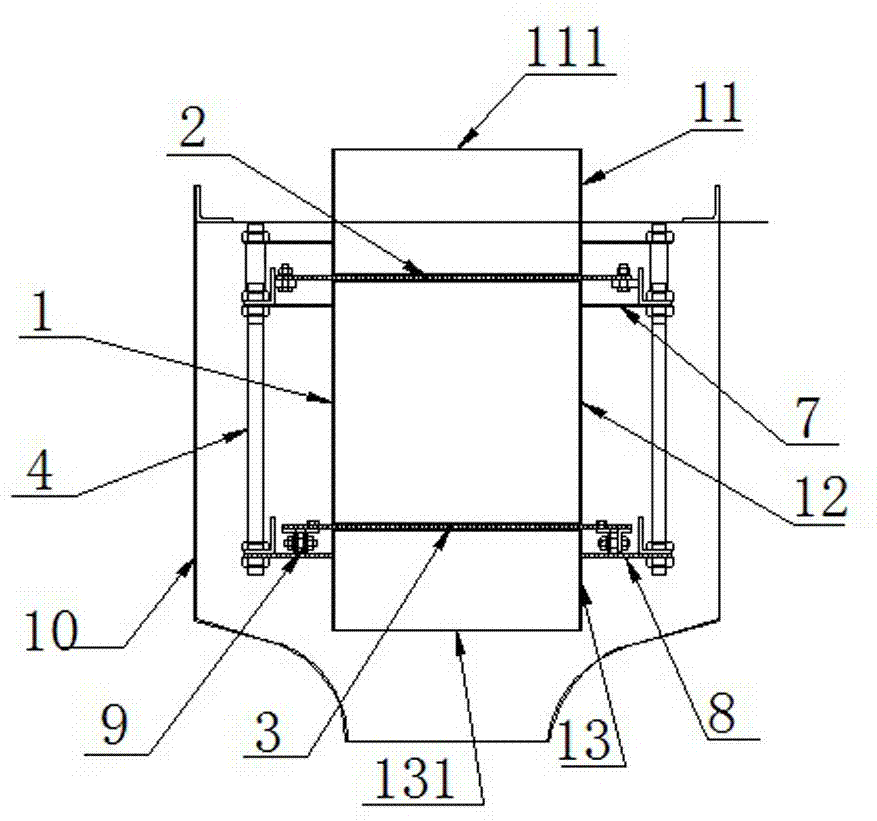

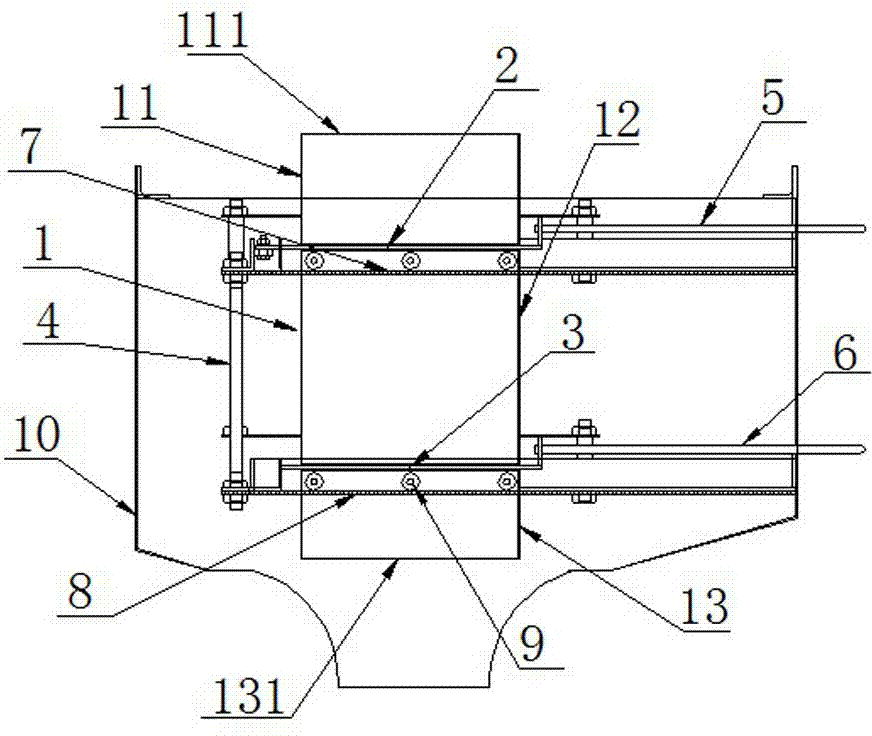

[0018] Embodiment: a quantitative feeding device, including a feeding channel 1, a first valve plate 2 and a second valve plate 3, the upper end of the feeding channel is a material inlet 111 and the lower end of the feeding channel is a material outlet 131. The first valve plate and the second valve plate are installed on the feeding channel in an up-and-down position relative to each other. When the first valve plate is closed, it can block the flow of materials in the feeding channel. When the second valve plate is closed, The flow of material in the feeding channel can be blocked, and the space between the first valve plate and the second valve plate forms a quantitative metering chamber. The principle and operation process of the quantitative feeding device are as follows: when working, close the second valve plate and open the first valve plate, the material enters from the feed port of the feeding channel, and then close the first valve plate, at this time the material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com