Air source heat pump heating system and control method thereof

An air source heat pump and heating system technology, applied in superheaters, refrigerators, refrigeration components, etc., can solve the problems of compressor suction temperature too high, unable to work normally, and unable to guarantee compressor suction temperature refrigerant temperature, etc. Achieve the effect of increasing the evaporation temperature and heat absorption, reducing the risk of liquid hammer, and improving the heating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

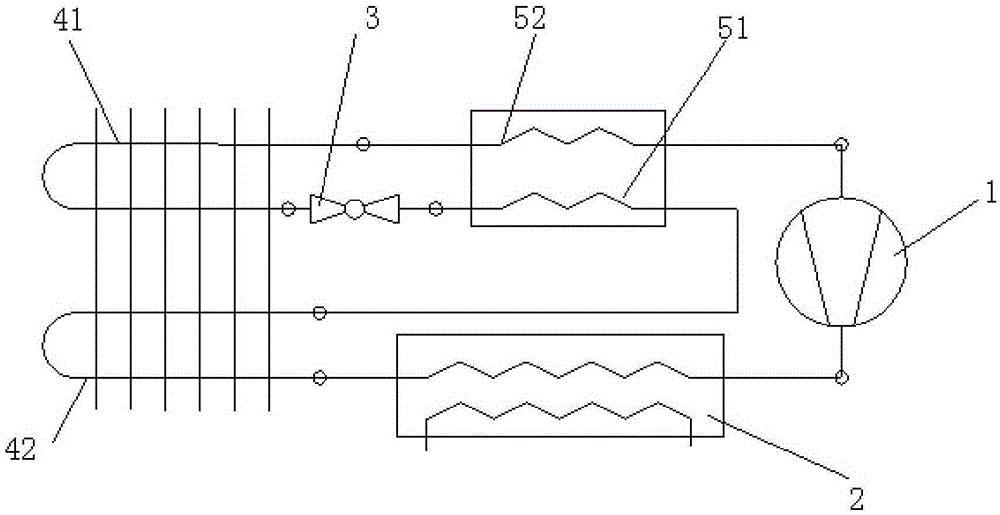

[0029] The preferred embodiment discloses an air source heat pump heating system. Such as figure 1 As shown, the air source heat pump heating system includes a compressor 1, a condenser 2, a throttling element 3 and a first evaporator 41 which are sequentially connected in series to form a circulation loop, wherein the throttling element 3 is preferably an expansion valve.

[0030] Between the refrigerant outlet of the condenser 2 and the refrigerant inlet of the throttling element 3 is communicated with the first branch of the regenerator 51; between the inlet of the compressor 1 and the refrigerant outlet of the first evaporator 41 is communicated with a regenerator The second branch 52; the second evaporator 42 is communicated between the refrigerant outlet of the condenser 2 and the refrigerant inlet of the first branch 51 of the regenerator, and the second evaporator 42 is used for the refrigerant flowing out of the condenser 2 heat exchange.

[0031] The specific conne...

Embodiment 2

[0041]This preferred embodiment discloses an air source heat pump heating system. In the air source heat pump heating system, the refrigerant can be but not limited to CO 2 , its structure is basically the same as that of the preferred embodiment 1. The air source heat pump heating system includes a compressor, a condenser, a throttling element, and a first evaporator connected in series to form a circulation loop, and a regenerator is connected between the refrigerant outlet of the condenser and the refrigerant inlet of the throttling element. A branch; between the inlet of the compressor and the refrigerant outlet of the first evaporator, there is a second branch of the regenerator; between the refrigerant outlet of the condenser and the refrigerant inlet of the first branch of the regenerator, there is a The second evaporator is used for exchanging heat for the refrigerant flowing out of the condenser.

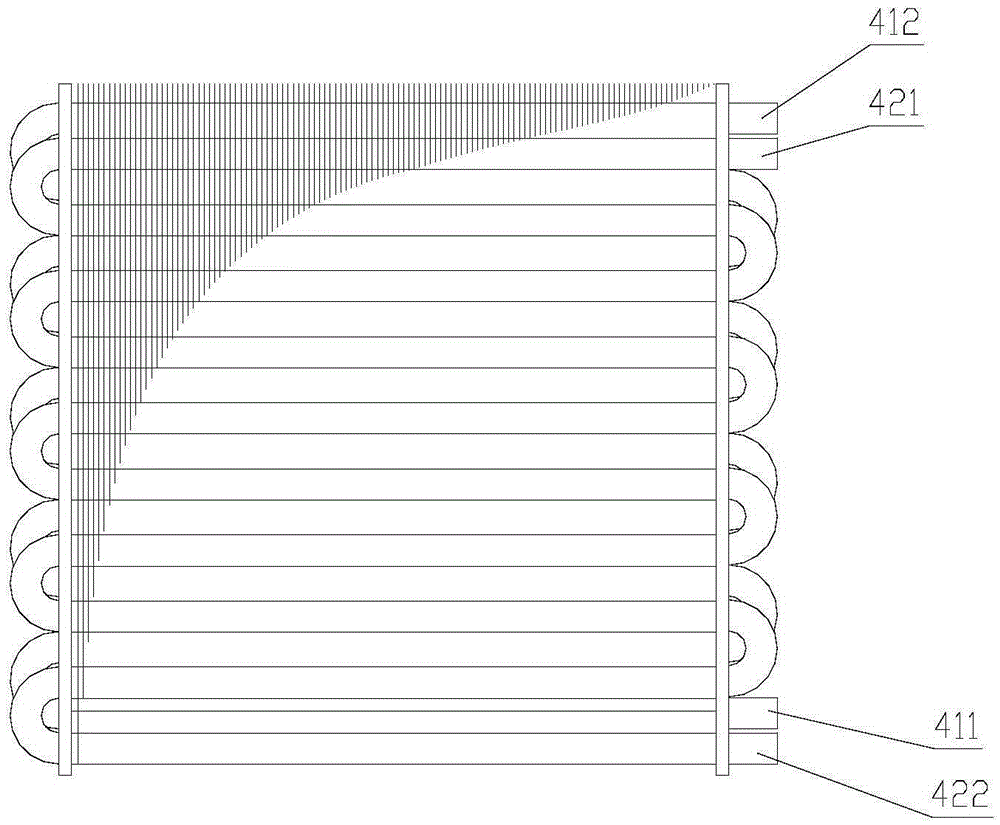

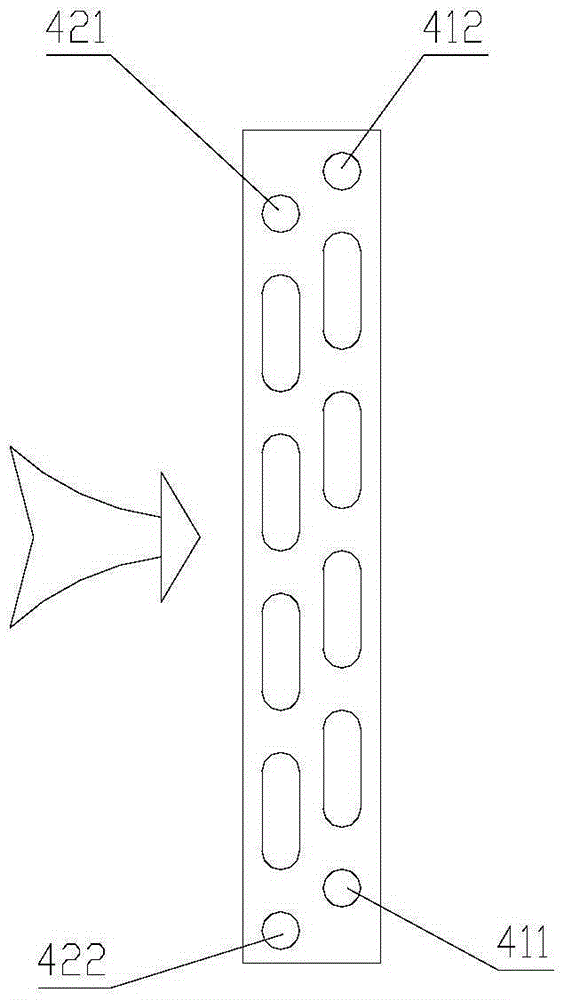

[0042] The difference is that the first evaporator and the second eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com