Door of diffusion furnace used for production of solar cell pieces

A technology of solar cells and diffusion furnaces, which is applied in the directions of diffusion/doping, circuit, crystal growth, etc., can solve the problems of injury to workers, achieve simple structure, and improve the effect of safe operation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

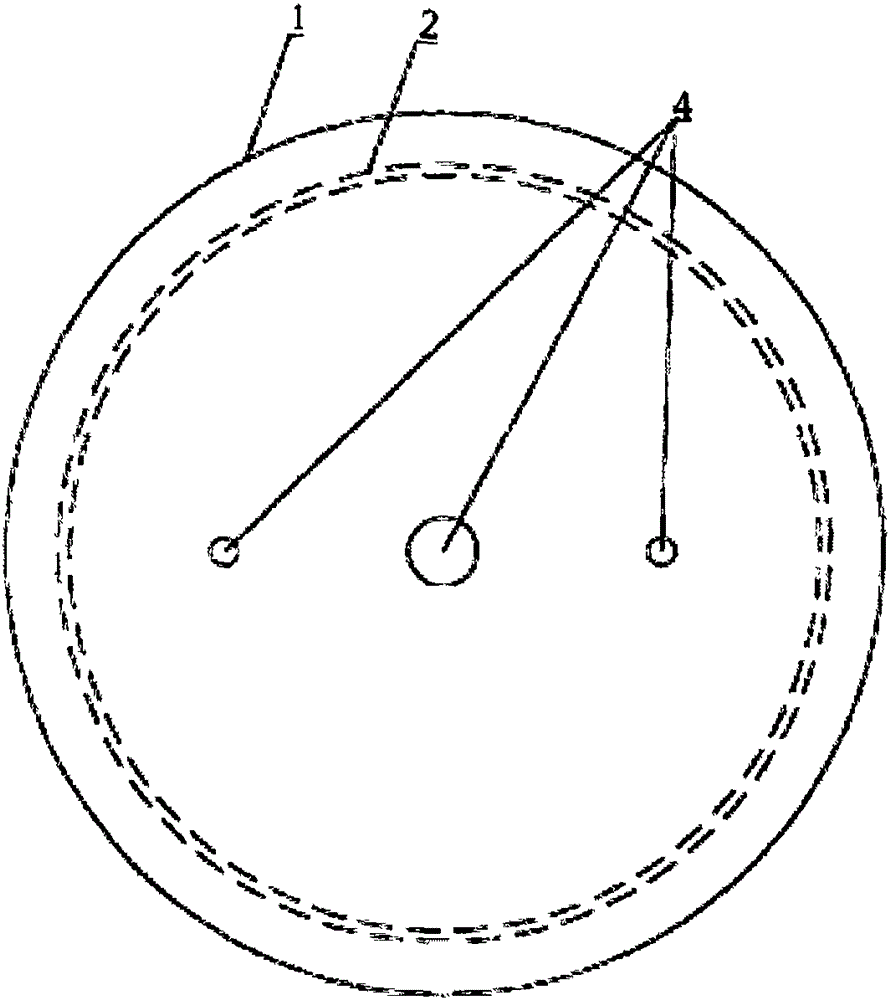

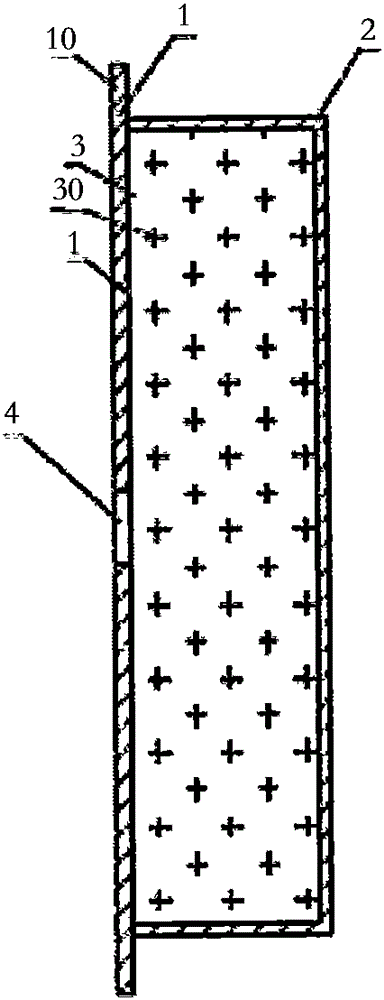

[0013] Such as figure 1 and 2 As shown, the furnace door of the diffusion furnace according to this embodiment includes a circular furnace door body 1, a door plate 2 forming an accommodating space 3 with the furnace door body 1, and quartz insulation cotton 30 filled in the accommodating space 3, The furnace door body 1 and the door plate 2 are made of opaque quartz glass.

[0014] The above-mentioned furnace door body 1 is provided with a plurality of filling ports 4, through which the quartz insulation cotton can be filled into the accommodation space 3, and at the same time, the furnace door body 1 also has the function of connecting it with the door plate 2. The outwardly extending flange 10 enhances the blocking effect of the furnace door on the furnace mouth of the diffusion furnace. The furnace door of the diffusion furnace of the present invention has a simple structure. Quartz insulation cotton is filled in the accommodating space formed by the door body and the do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com