Organic fertilizer fermentation tank

A fermentation tank and organic fertilizer technology, applied in the direction of organic fertilizers, fertilization devices, excretion fertilizers, etc., can solve the problems of poor fermentation effect and inability to ferment manure, and achieve the goals of shortening fermentation time, good economic benefits, and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

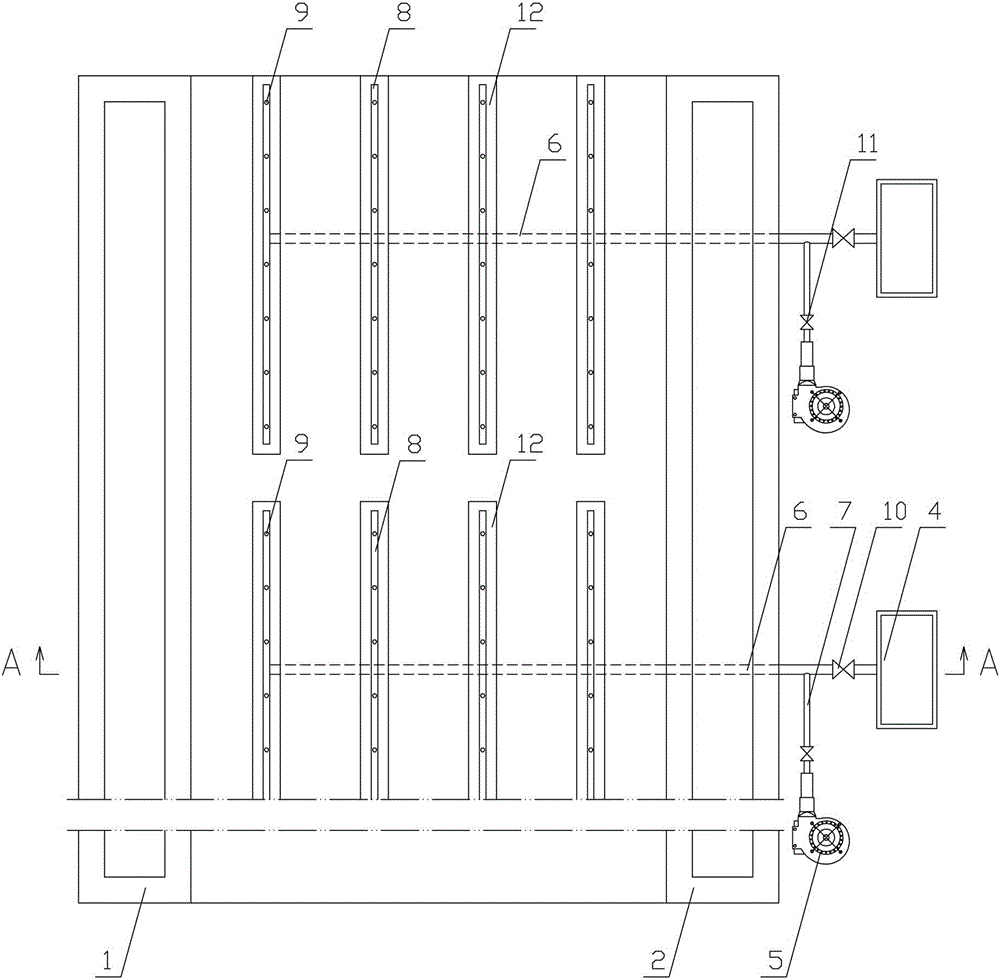

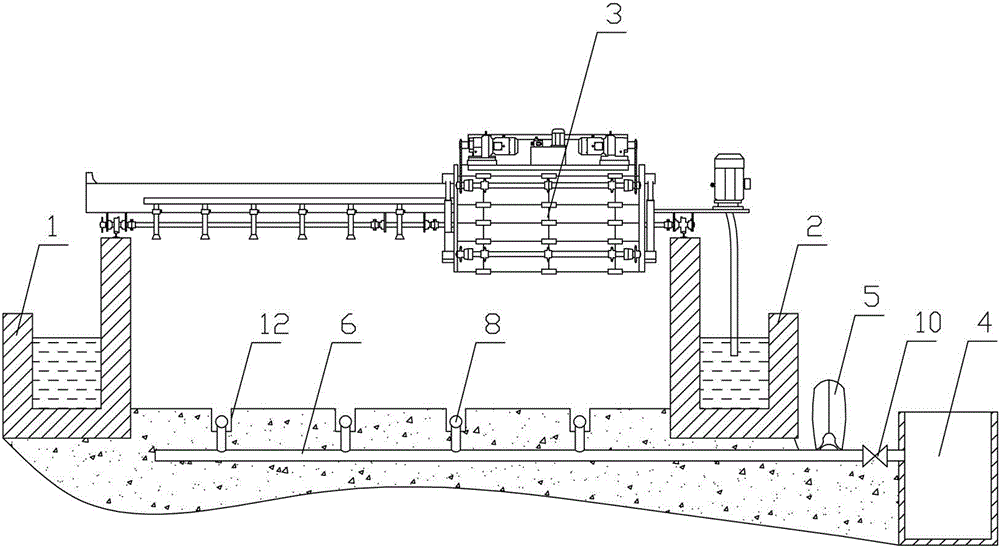

[0015] see Figure 1-2 , the present invention has left and right slurry tanks 1,2 arranged side by side. The body is equipped with a turning device 3, especially: several groups of aeration and excrement recovery systems are arranged in the fermentation tank body, and each group of aeration and excrement recovery systems includes a liquid collection tank 4, a high-pressure air pump 5, and a water collection pipe. 6. Air pipe 7 and a number of aeration pipes 8, wherein the tank edge of liquid collection tank 4 is flush with the ground, liquid collection tank 4 is connected to water collection pipe 6, water collection pipe 6 is connected to air transmission pipe 7 and aeration pipe 8, aeration An air eye 9 is provided on the pipe 8, and an on-off valve A10 is installed on the water collection pipe 6 between the air pipe 7 and the sump 4, the gas input end of the air pipe 7 is connected to the high-pressure air pump 5, and an on-off valve is installed on the air pipe 7 B11; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com