Two-way conveying equipment and application method thereof

A two-way conveying and equipment technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of restricting filling capacity, low efficiency of conveyor belt use, and single function of conveyor belt, so as to increase equipment utilization and reduce Transportation links, the effect of reducing transportation accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. However, it will be understood by those skilled in the art that the present invention may be practiced without these specific details.

[0023] The present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

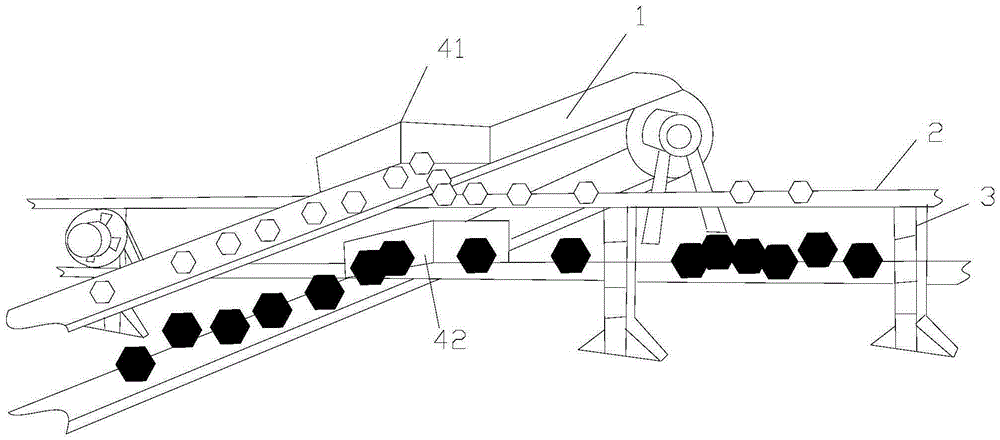

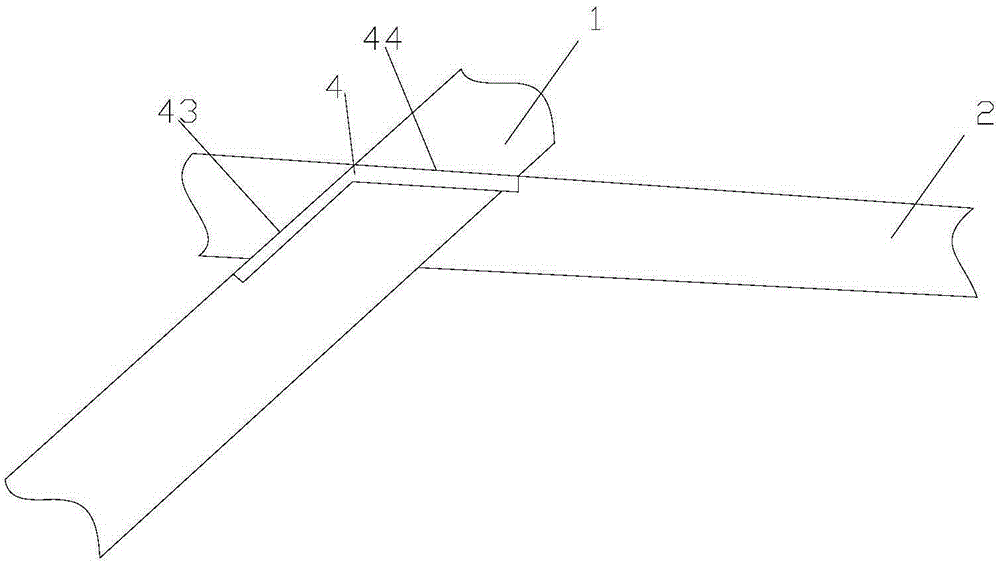

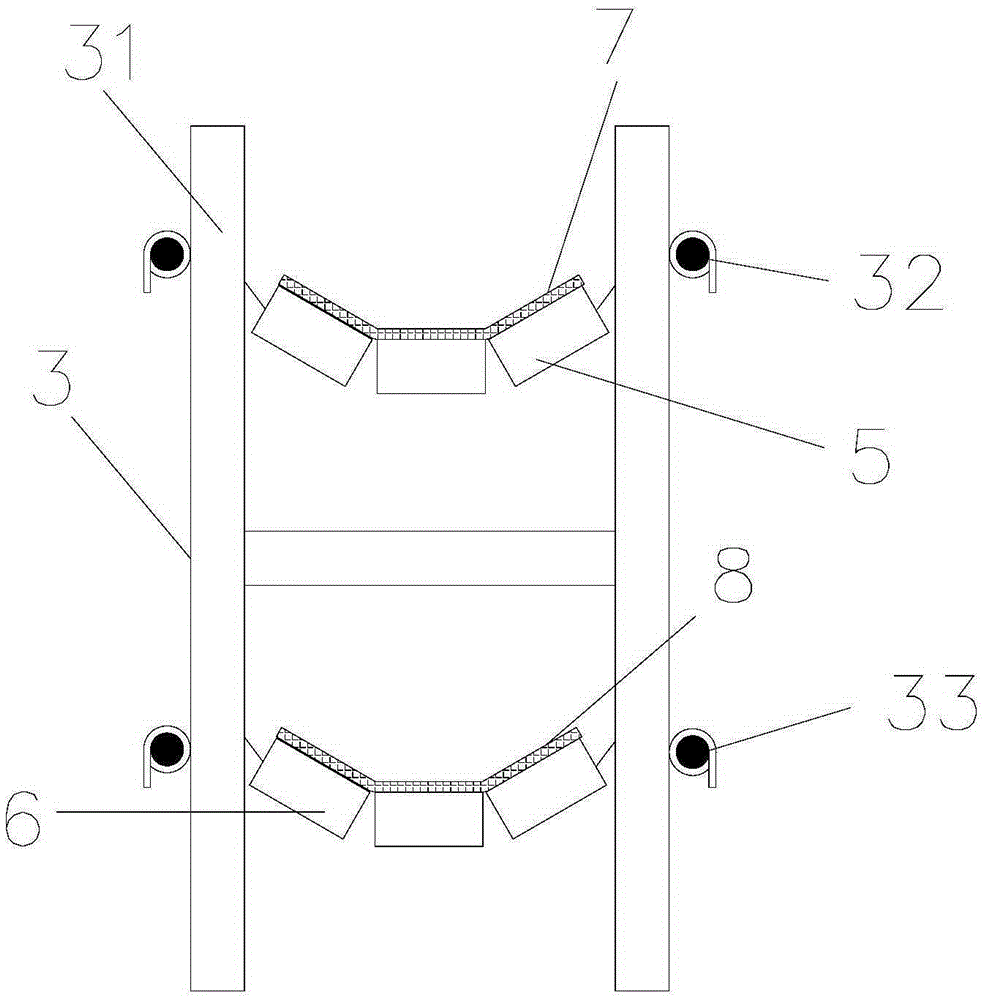

[0024] In some illustrative examples, such as figure 1 , figure 2 , image 3 As shown, a two-way conveying device is disclosed, comprising a belt conveyor and a support 3, the belt conveyor has an endless conveyor belt, and there are multiple belt conveyors, including the upper belt conveyor 1 and the lower-level belt conveyor 2; the upper-level belt conveyor 1 and the lower-level belt conveyor 2 constitute a relay-type conveying structure; the lower-level belt conveyor 2 passes through the The endless conveyor belt of the upper-level belt conveyor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com