Light alkane dehydrogenation catalyst and its preparation method and use

A dehydrogenation catalyst, a technology for low-carbon alkanes, applied in the direction of hydrocarbons, hydrocarbons, metal/metal oxide/metal hydroxide catalysts, etc. problems such as anchoring, to achieve the effect of high activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

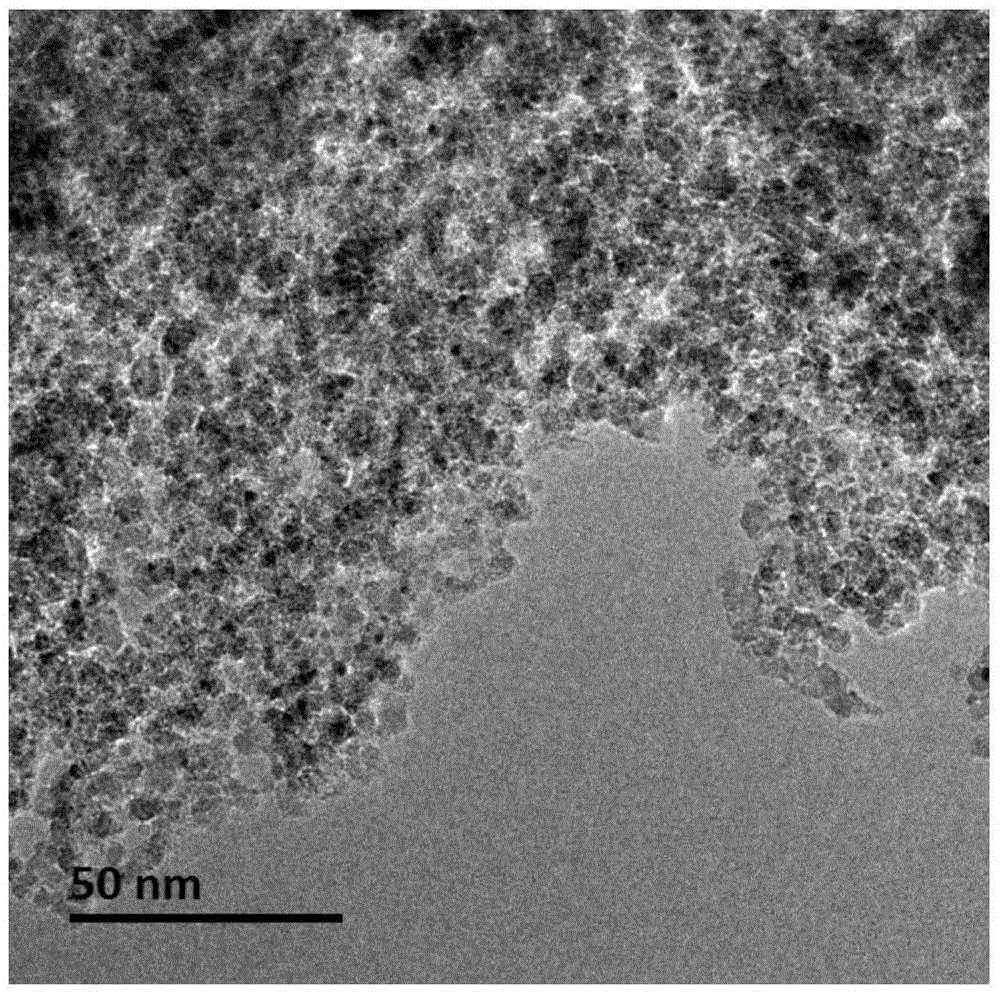

[0016] The preparation method of the catalyst of the invention comprises the steps of calcining the nano-diamond at 1000-1400 DEG C in an inert gas, impregnating it with a platinum-containing compound solution, drying it in the air, and then reducing it.

[0017] In the above method, the calcining temperature of the nano-diamond in an inert gas is preferably 1000-1200°C. The inert gas is preferably nitrogen. The firing time is preferably 2-20 h, more preferably 2-8 h.

[0018] After the nano-diamond is baked in an inert gas, it is impregnated with a platinum-containing compound, and the platinum-containing compound is selected from platinum nitrate, chloroplatinic acid, potassium chloroplatinate, dichlorotetraammine platinum or platinum acetylacetonate. The liquid / solid ratio during immersion is preferably 50 to 70 mL / g, and the immersion temperature is preferably 15 to 45°C. The platinum content in the platinum-containing compound solution used for impregnation is preferabl...

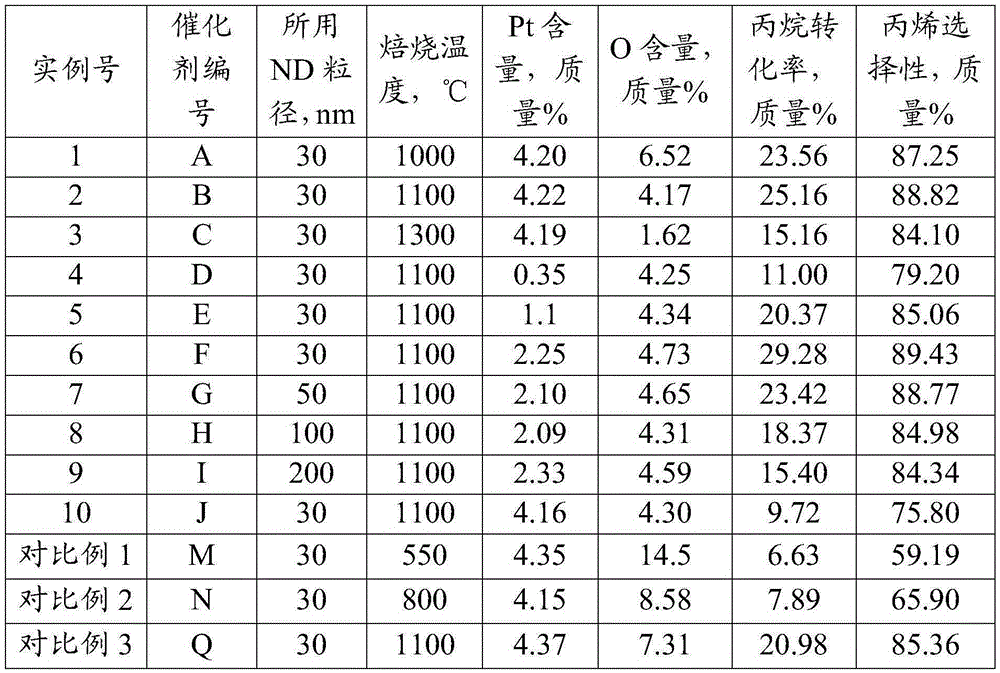

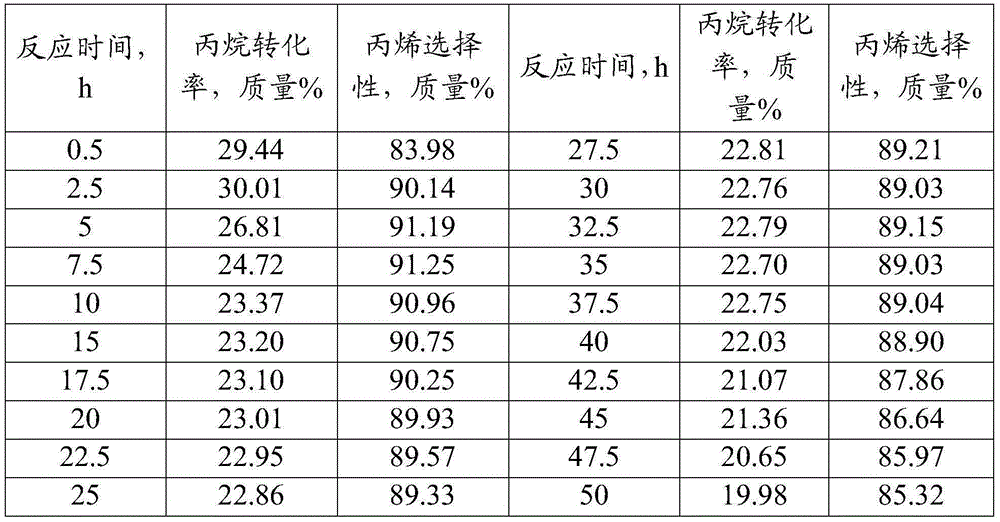

example 1

[0026] Preparation of catalyst of the present invention and performance evaluation of propane dehydrogenation

[0027] (1) Preparation of catalyst

[0028] Take nano-diamond ND-30 with a particle size of 30nm, in N 2 Baked at 1000°C for 18 hours. Take 1.0g in N 2 The nano-diamonds after medium roasting were put into 8.6mL of chloroplatinic acid solution with a Pt content of 5.8mg / mL and 55.4mL of deionized water, treated with ultrasonic waves at 25°C for 3h, stirred for another 48h, and dried at 110°C for 24h; Reduction in a sodium formate solution with a concentration of 15mg / mL for 1 hour at 100°C, the molar ratio of sodium formate to Pt used was 15:1, and dried at 60°C for 18 hours to obtain catalyst A with a pore diameter of 11.7nm and a specific surface area of 340m 2 / g, the total pore volume is 0.796cm 3 / g (according to nitrogen absorption-desorption curve, adopt BET equation to obtain specific surface area, adopt BJH equation to obtain pore diameter and total por...

example 2

[0032] Catalyst is prepared by the method for example 1 and carries out propane dehydrogenation reaction, and difference is (1) in step with nanodiamond in N 2 The catalyst B was calcined at 1100°C. The contents of platinum and oxygen in the prepared catalyst B and the results of propane dehydrogenation reaction are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com