Fractional crystallization analysis method of polyolefin resin

A polyolefin resin, fractional crystallization technology, applied in the analysis of materials, material crystallization, material thermal analysis and other directions, can solve the problems of inaccurate reaction of key properties, inconvenient selection of polyolefins, complex results, etc., to improve the accuracy of selection, Reduce time and cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

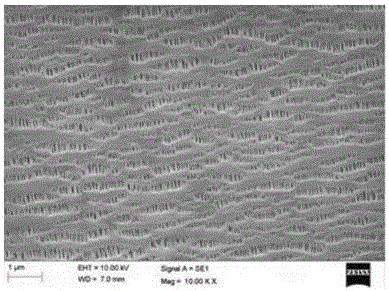

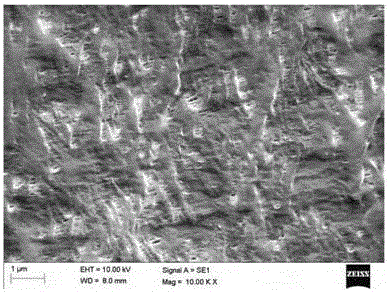

Image

Examples

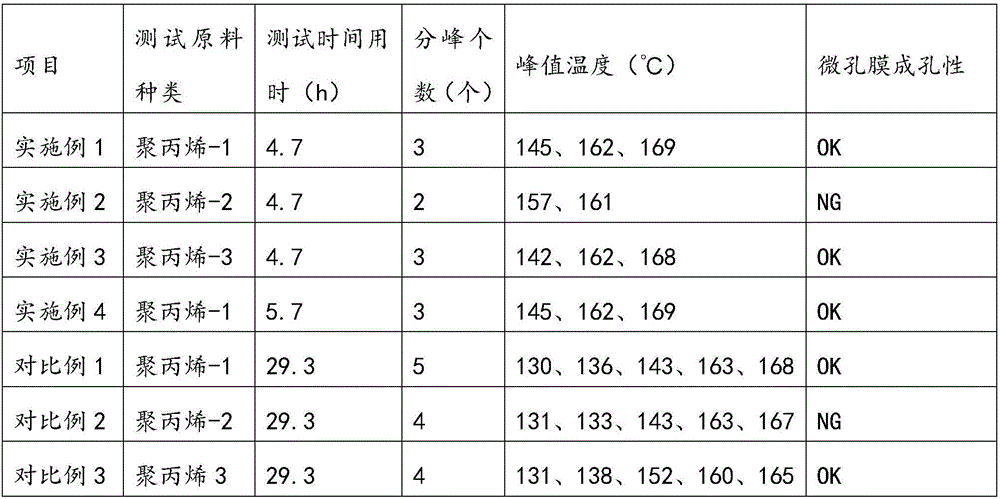

Embodiment 1

[0033] The present embodiment provides a method for fractional crystallization analysis of polyolefin resins. The test raw material is polypropylene-1 (conforming to the requirements for preparing qualified microporous membranes for lithium-ion batteries), and the specific steps are as follows:

[0034] 1. The differential scanning calorimeter was turned on and preheated for 30 minutes, and 5 mg of the test sample was put into the test crucible. During the whole test process, N 2 Protect;

[0035] 2. Constant temperature at 50°C for 2 minutes;

[0036] 3. Raise the temperature to 220°C at a constant speed of 10°C / min, and keep the temperature constant for 6 minutes to eliminate the thermal history of the sample;

[0037] 4. Cool down to 165°C at a constant speed of 10°C / min, and keep the temperature constant for 80 minutes;

[0038] 5. Cool down to 50°C at a constant speed of 50°C / min;

[0039] 6. Raise the temperature to 148°C at a constant speed of 10°C / min, and keep the ...

Embodiment 2

[0046] This example provides a method for fractional crystallization analysis of polyolefin resins, the steps are the same as in Example 1, except that the test raw material is polypropylene-2.

Embodiment 3

[0048] This example provides a method for fractional crystallization analysis of polyolefin resins, the steps are the same as in Example 1, except that the test raw material is polypropylene-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com