No-scaling fluidized bed heat exchanger

A fluidized bed heat exchanger and heat exchanger technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of decreased heat exchange effect and easy scaling of heat exchanger tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

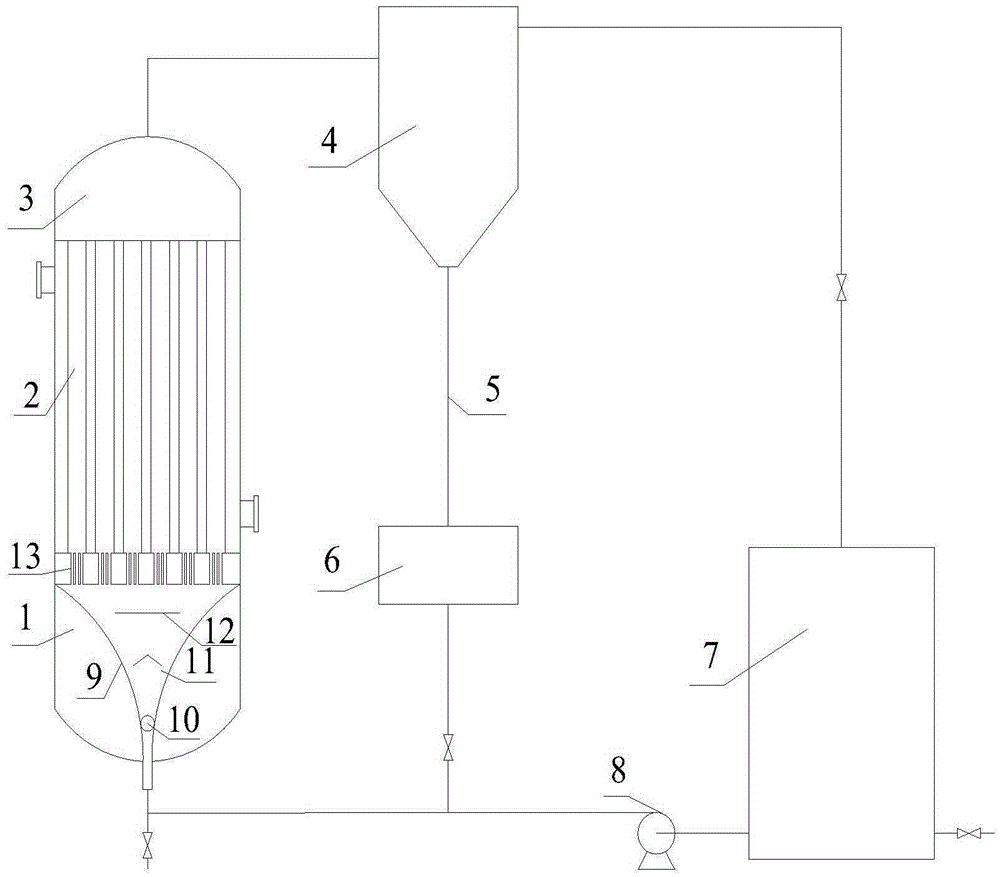

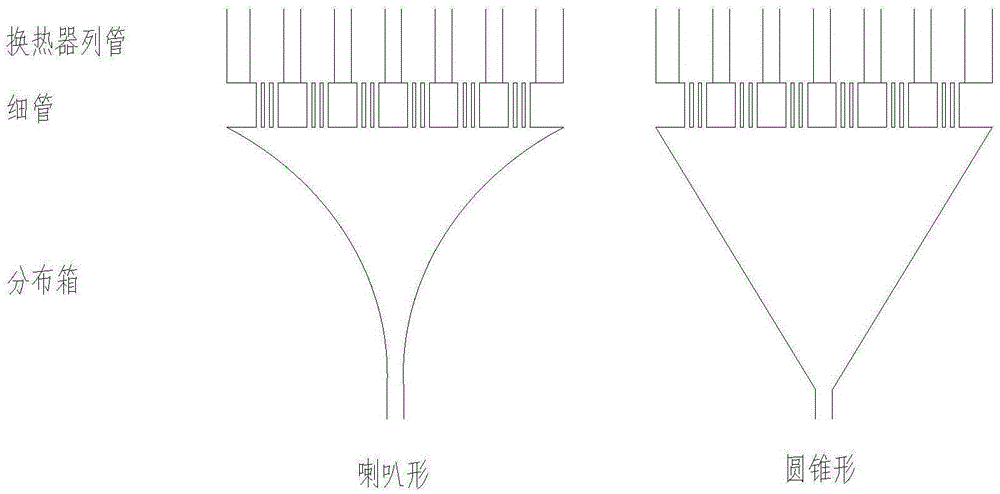

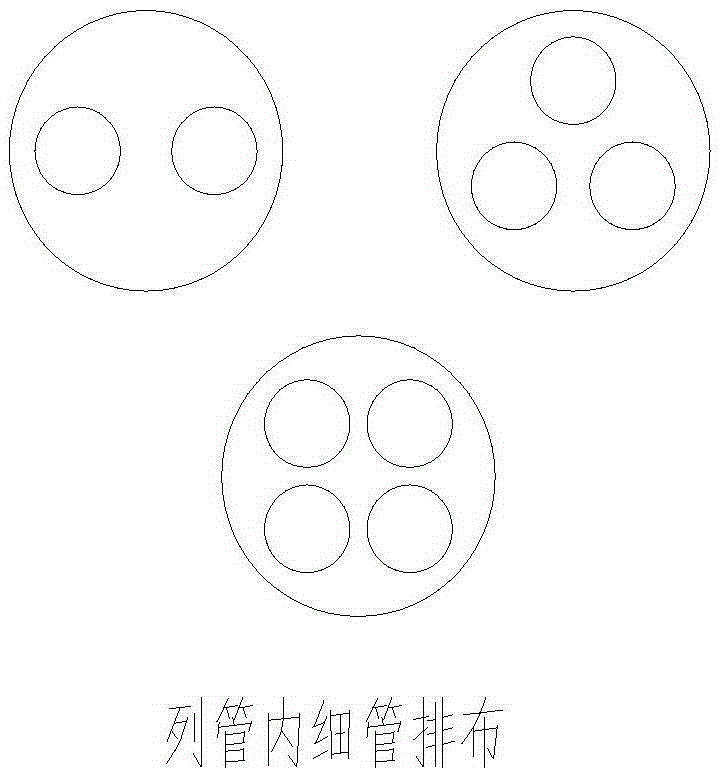

[0033] use figure 1 The non-fouling fluidized bed heat exchanger shown is applied to the refining tower condenser of a methyl tert-butyl ether plant. The non-fouling fluidized bed heat exchanger is equipped with 600 heat exchanger tubes, and each tube The length is 3000mm, the pipe diameter is Φ22×1.5mm, and the pipes are arranged in an equilateral triangle. The solid particles are glass beads with an average particle diameter of 5 mm, and the average volume solid content of the solid particles in the non-fouling fluidized bed heat exchanger is 3%. The liquid phase is circulating cooling water with a flow rate of 1.5m / s. The distribution bin is figure 2 Conical shape shown. Distribution box height 300mm. The diameter of the narrow tube is 6mm, the length is 8mm, and there are 4 thin tubes arranged in each heat exchanger tube. The diameter of the spherical plug is twice the diameter of the inlet of the lower tube box. bezel for Figure 4 For the plate type shown, the ma...

Embodiment 2

[0035] The same non-fouling fluidized bed heat exchanger as in Example 1 is applied to the refining tower condenser of a certain methyl tert-butyl ether plant. The solid particles are glass beads with an average particle diameter of 2 mm. The solid particles are in the non-fouling flow The average volume solid content in the fluidized bed heat exchanger is 8%. The liquid phase is circulating cooling water with a flow rate of 4m / s. The distribution bin is figure 2 Trumpet shown. The height of the distribution box is 900mm. The diameter of the narrow tube is 6mm, the length is 15mm, and there are 4 thin tubes arranged in each heat exchanger tube. The diameter of the spherical plug is 1.2 times the diameter of the inlet of the lower tube box. bezel for Figure 4 For the reverse roof type shown, the maximum length of the vertical projection is 0.3 times the diameter of the heat exchanger cylinder. The distribution plate is Figure 5 The shown single-layer convex circular p...

Embodiment 3

[0037] The same non-fouling fluidized bed heat exchanger as in Example 1 is applied to the refining tower condenser of a certain methyl tert-butyl ether plant. The solid particles are made of alumina beads with an average particle size of 5mm, and the solid particles do not scale in this The average volume solid content in the fluidized bed heat exchanger is 3%. The liquid phase is circulating cooling water with a flow rate of 1.5m / s. The distribution bin is figure 2 Conical shape shown. The distribution box height is 300mm. The diameter of the narrow tube is 6mm, the length is 8mm, and there are 3 thin tubes arranged in each heat exchanger tube. The diameter of the spherical plug is twice the diameter of the inlet of the lower tube box. bezel for Figure 4 For the propeller type shown, the maximum length of the vertical projection is 0.1 times the diameter of the heat exchanger cylinder. The distribution plate is Figure 5 The shown single-layer downward-convex grid b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com