Non-excavation and top drilling combined crossing and spanning pipeline laying method

A laying method and non-excavation technology, applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc., can solve problems such as pipeline laying in complex strata, achieve convenient pipeline operation, long crossing distance, and prevent water gushing Effects of sand gushing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

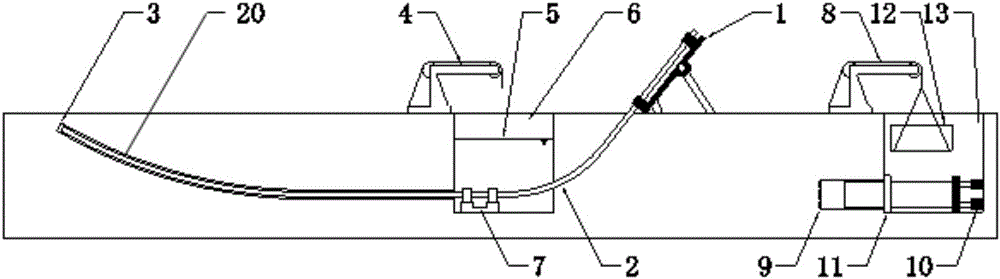

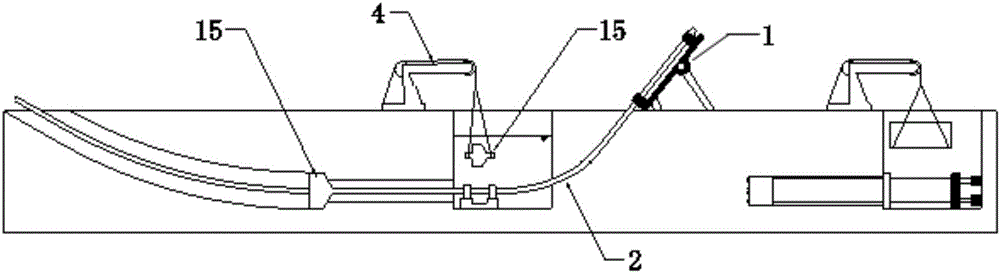

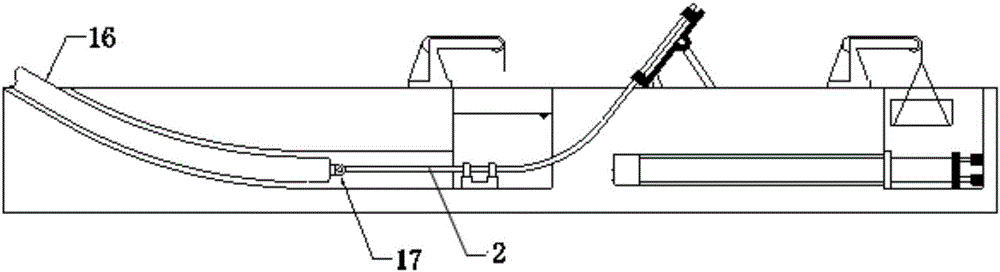

[0033] The present invention will be further described below in conjunction with drawings and embodiments.

[0034] The invention provides a method for laying a non-excavation drill roof combined crossing and spanning pipeline, which includes the following steps:

[0035] (1) According to geological survey data and pipeline design data, respectively select sections suitable for horizontal directional drilling rig technology and pipe jacking technology, and select the positions of pipe jacking working wells and receiving wells;

[0036] (2) The pipe jacking working well and the receiving well are completed, so that the depth of the pipe jacking working well and the receiving well is the same;

[0037] (3) Water injection 5 to the receiving well, pipe jacking construction and horizontal directional drilling rig construction are carried out simultaneously, so that the position to be laid at the bottom of the receiving well is opened; wherein, the horizontal directional drilling r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com