Zero resistance flue check valve

A technology of check valve and flue, which is applied in the direction of valve device, control valve, function valve type, etc., can solve the problems of endangering physical and mental health, pollution, and inability to completely discharge indoor fumes, etc., achieve zero resistance and direct air discharge, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

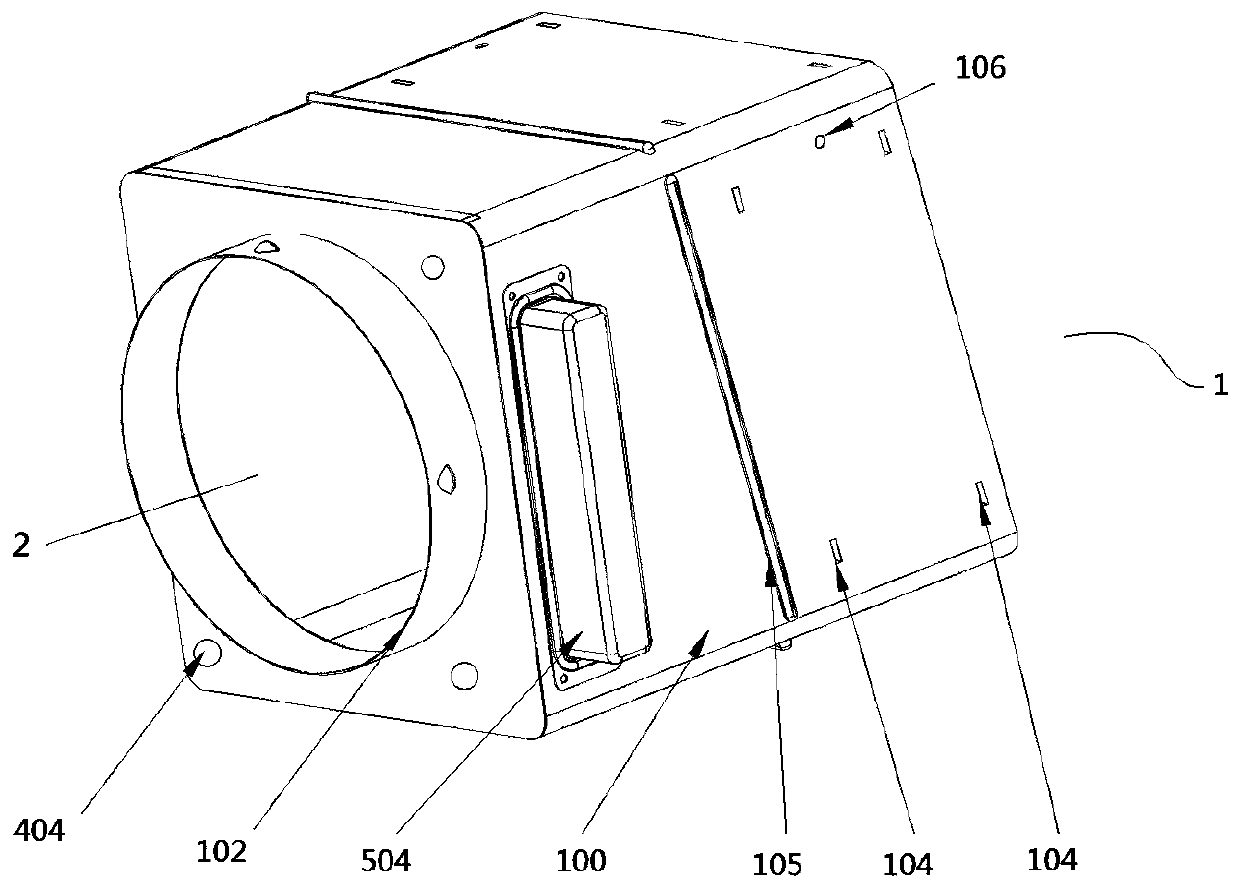

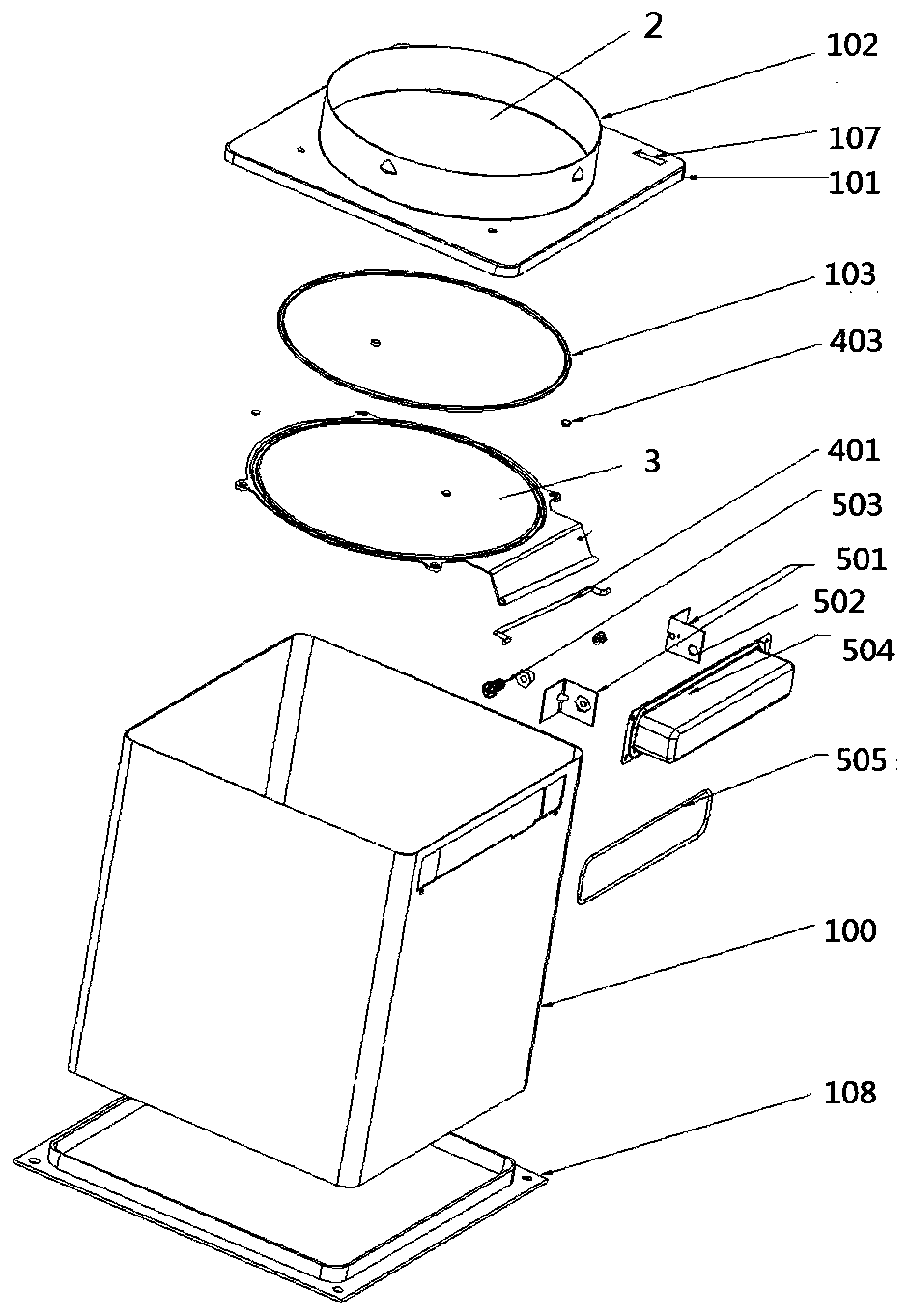

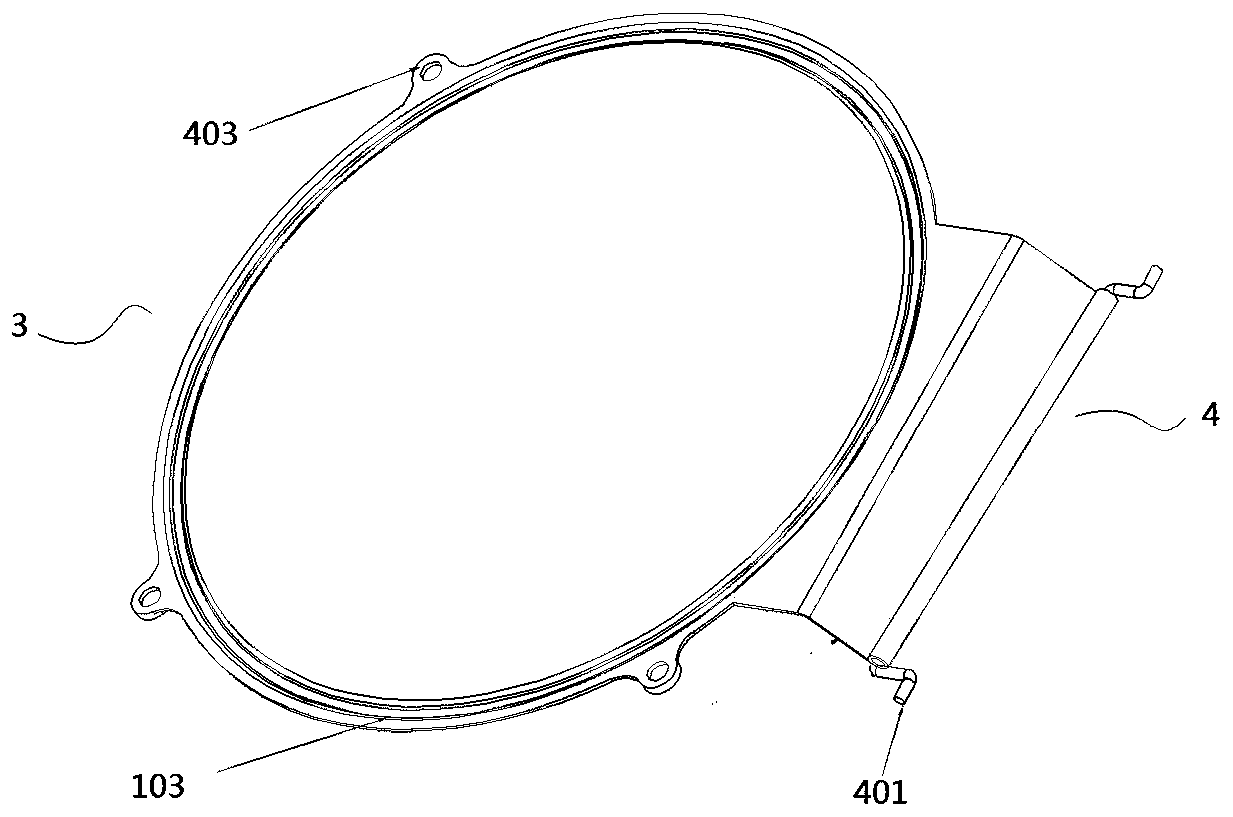

[0019] Such as Figure 1-2 As shown, the zero-resistance flue check valve of the present invention includes a valve body 1, which can be composed of a square shell 100 and an upper cover 101 located at one end of the square shell 100, wherein an air hole 2 is opened in the middle of the upper cover 101, And a section extends outward from the air hole 2 to form an external connection 102 , and an upper cover level 107 can be provided on the upper cover 101 as required. The present invention is provided with a monolithic valve 3 at the vent hole 2. One side of the valve 3 extends outward for a section and passes through the side wall of the valve body to bend obliquely. The width of the upper and lower ends of the bent part is not equal. Install door shaft 4 at the bent end, such as Figure 3-4 As shown, since the width of the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com