Reduced-pressure type backflow preventer

A backflow preventer and check valve technology, which is applied in the field of pipeline valves, can solve the problems of easy loosening of parts, time-consuming and material consumption, etc., and achieve the effect of stable opening, convenient replacement of parts and cleaning, and good prevention of backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

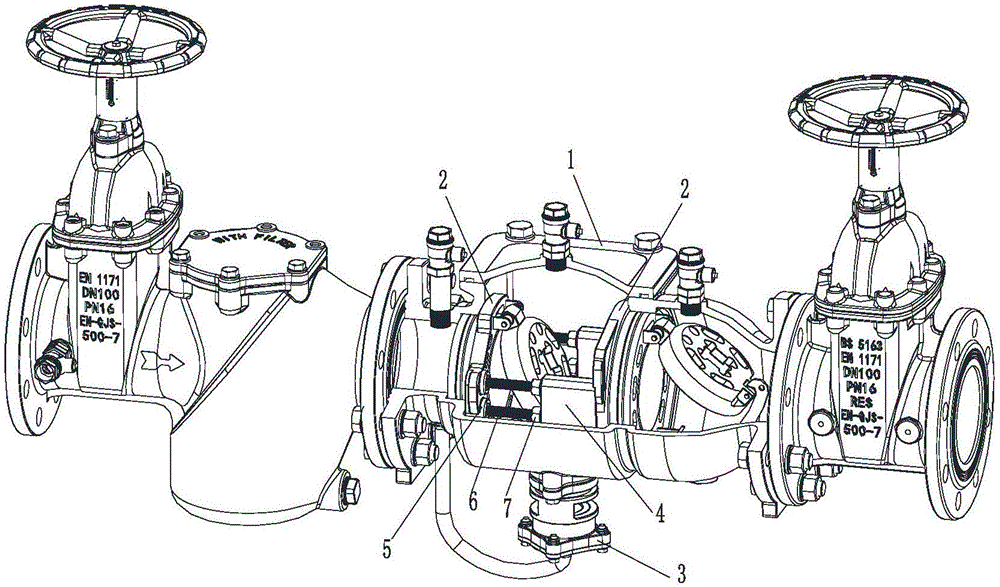

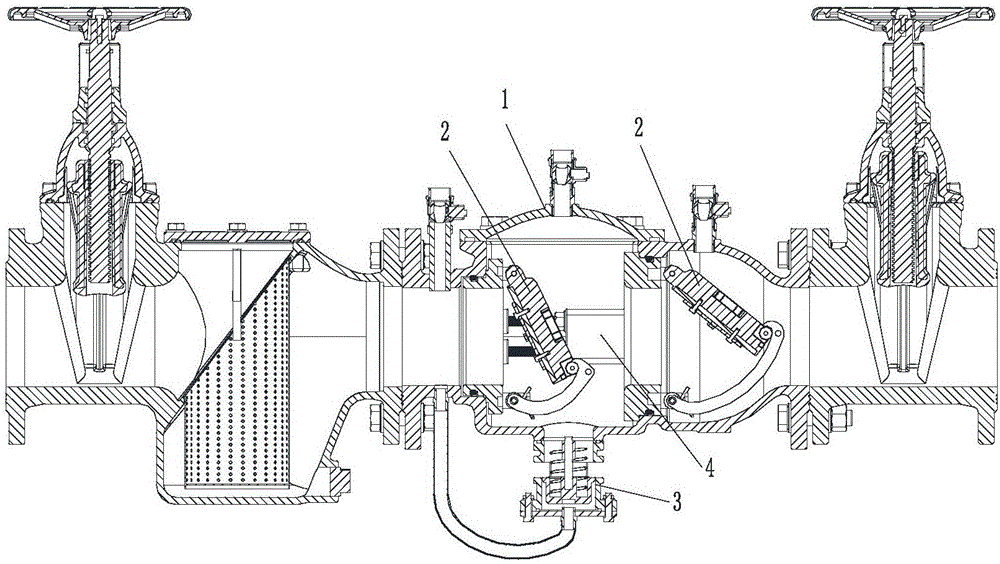

[0039] Such as Figure 1-14 As shown, a decompression type backflow preventer includes a valve body 1, two check valves 2 with the same structure and a drain valve 3; a cavity is formed inside the valve body, and the valve wall of the valve body has an inlet A water outlet, a water outlet, and a water discharge port; the two check valves are fixedly installed in the valve body through the support member 4, and are respectively located at the water inlet and the water outlet; the water discharge valve is installed outside the valve body, located at the water discharge port;

[0040] The check valve 2 includes a valve seat 201, a valve disc 202, a rocker 203, and a double torsion spring 204; one side of the valve disc is hinged on the upper end of the valve seat, and a roller 205 is installed on the other side of the valve disc; One end of the rocker is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com