A centralized control system and method for an air compressor system

A centralized control system and control system technology, which is applied in the direction of pump control, liquid variable displacement machinery, machine/engine, etc., can solve the problems of increasing the cost of later maintenance, not being able to control the air pressure system, and reducing the service life, etc., to achieve convenience Effects of overhaul and maintenance, labor intensity reduction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

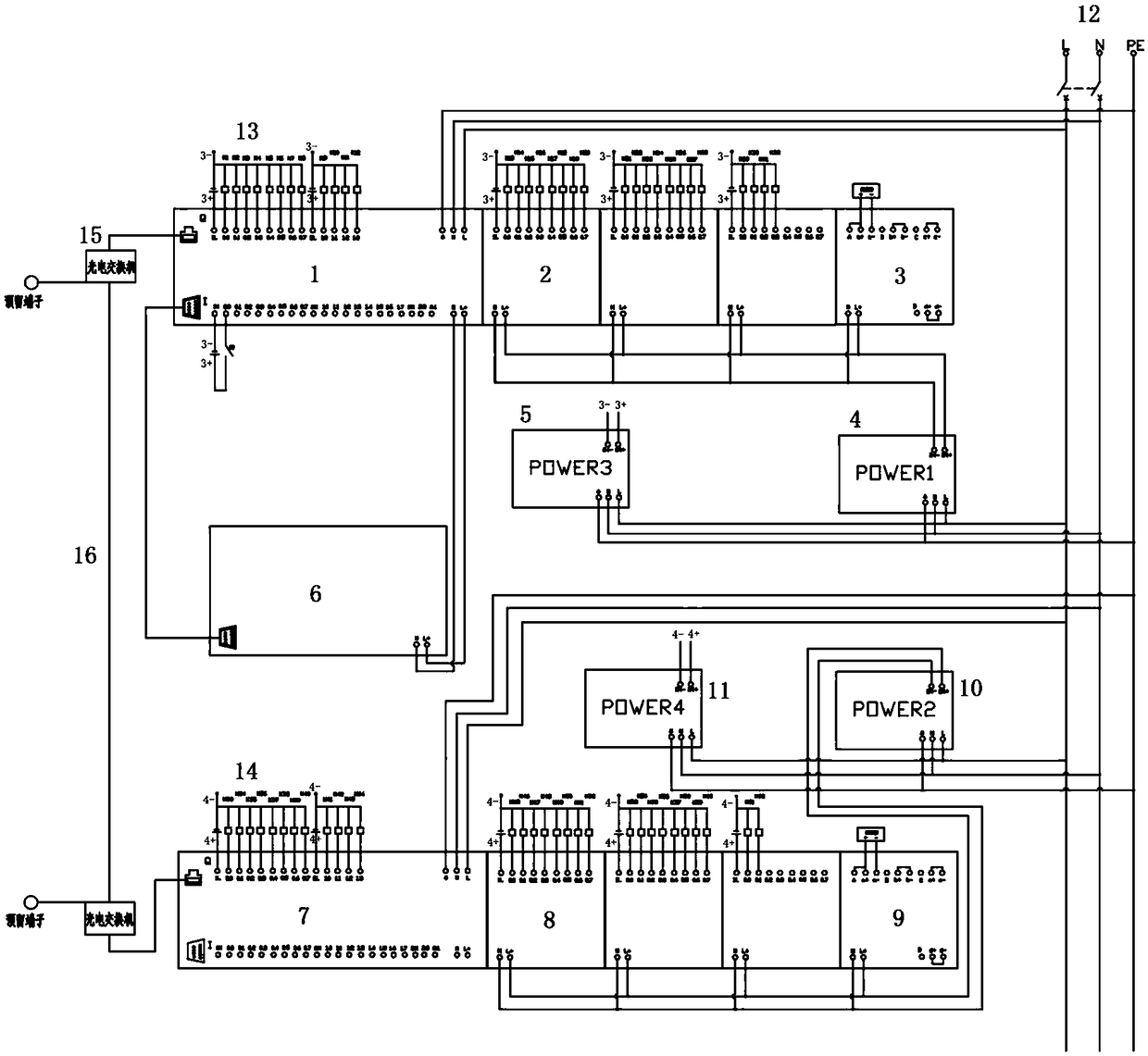

[0030] Such as figure 1In the described embodiment, a centralized control system about the air compressor system includes a master station control system, a slave station control system and a touch screen 6, the touch screen 6 is connected to the master station control system, the master station control system and the slave station control system All are equipped with photoelectric transceivers 15, and the photoelectric transceivers 15 on the master station control system are connected with the photoelectric transceivers 15 on the slave station control system through multimode optical fibers 16. Wherein: it also includes an alarm module, the touch screen 6 is provided with a storage module and a USB interface, the alarm module is connected with the touch screen 6, and the photoelectric transceiver 15 is provided with a reserved port.

[0031] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com