An automatic installation system for railway t-beam steel formwork

An automatic installation and steel formwork technology, which is applied to fluid pressure actuation system components, fluid pressure actuation devices, molds, etc., can solve the problems of gantry cranes that cannot be synchronized, poor control accuracy, and low operating safety factor, so as to improve mobile work. Efficiency, improvement of construction safety, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

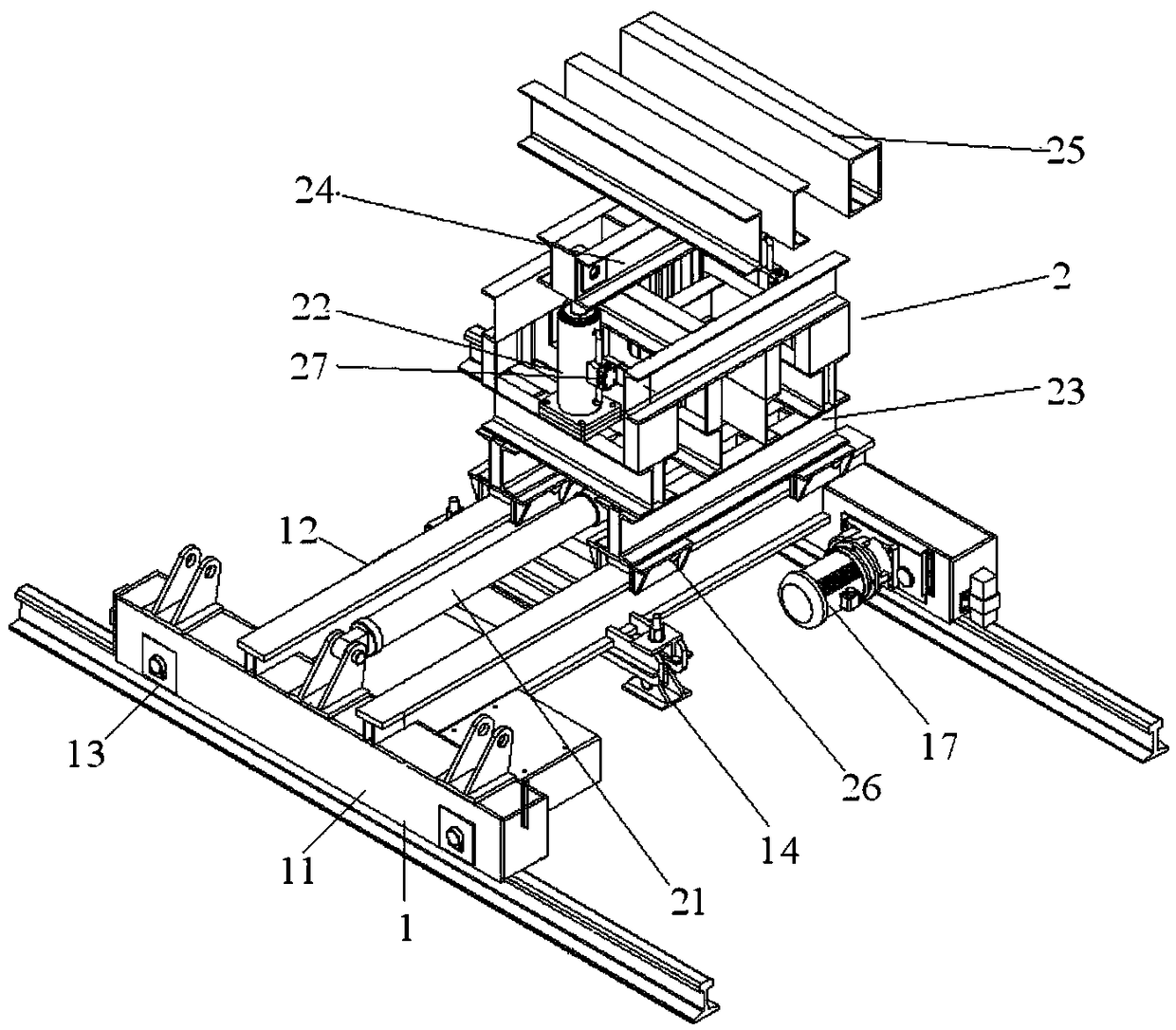

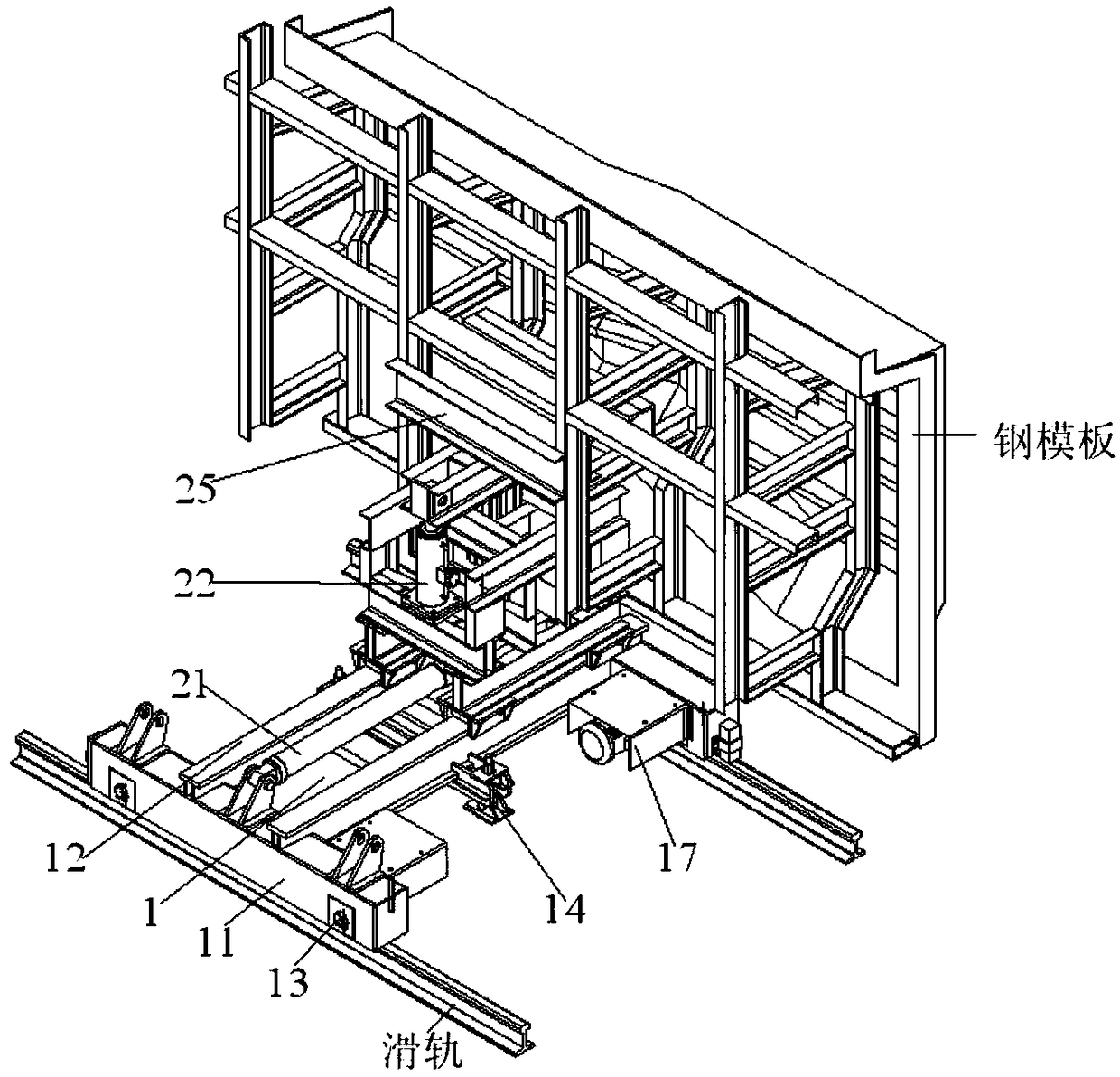

[0044] Comply with the above technical solutions, such as Figure 2 to Figure 13 As shown, this embodiment provides an automatic installation system for railway T-beam steel formwork, including trolley walking equipment 1, automatic lifting equipment 2 and hydraulic station system 3;

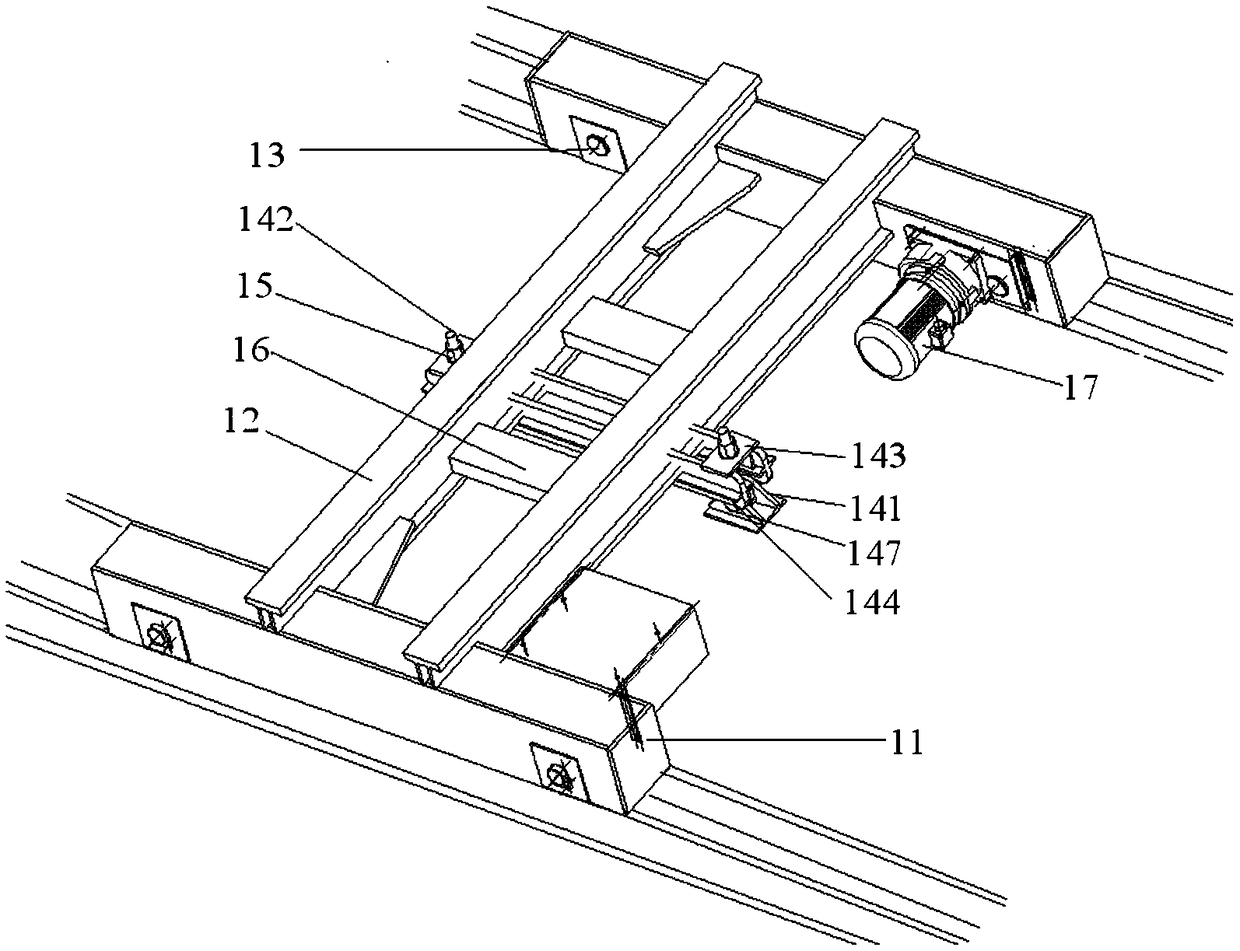

[0045] The trolley walking equipment 1 includes cross beams 11 parallel to each other. Longitudinal beams 12 parallel to each other are connected between the cross beams 11. Walking wheels 13 are arranged on the bottom of the cross beams 11. An anti-dumping mechanism 14 is installed on the longitudinal beams 12. The anti-dumping mechanism includes ear seats 141, movable trunnion 142, fastening plate 143 and support plate 144, the center of fastening plate 143 is processed with through hole 145, the lower surface of fastening plate 143 is provided with two parallel vertical plates 146, ear seat 141 and movable One end of the trunnion 142 is connected by a bolt 147, and the other end of the movabl...

Embodiment 2

[0062] The railway T-beam steel formwork automatic installation system of the present invention has been used in the actual construction of railway prefabricated beams and has achieved good results, as follows:

[0063] (1) Calculation of economic benefits before and after using the automatic installation system of railway T-beam steel formwork of the present invention, according to conventional construction, most parts of the system need to be hoisted and manually transported, using the present invention to realize overall movement, faster speed, and significantly reduced labor intensity , adopting the system of the present invention greatly reduces the cost expenditure and obtains better social and economic benefits.

[0064] The comparison is made from the three aspects of required team members, mold removal and installation time, and benefit analysis. The results are as follows:

[0065]

[0066]

[0067] (2) use the comparison of prefabricated T beam quality inspect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com