A structure and construction method of improving the tunnel lining shock absorption capacity

A technology of shock absorption capacity and construction method, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of increased internal force of support structure, increased seismic inertial force, and lining collapse, so as to reduce the damage of lining structure, The effect of reducing earthquake disaster losses and simple and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

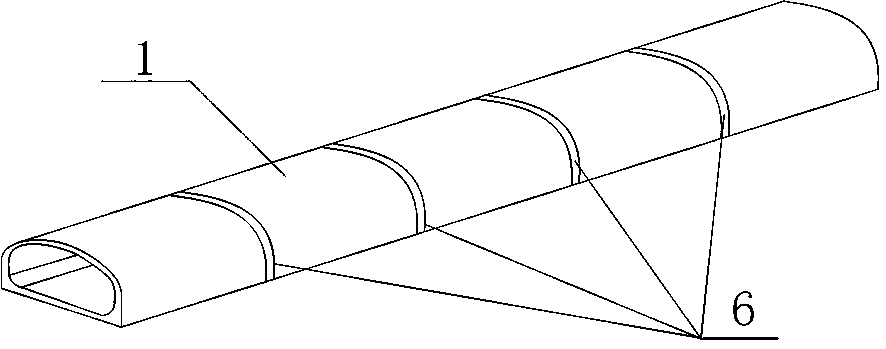

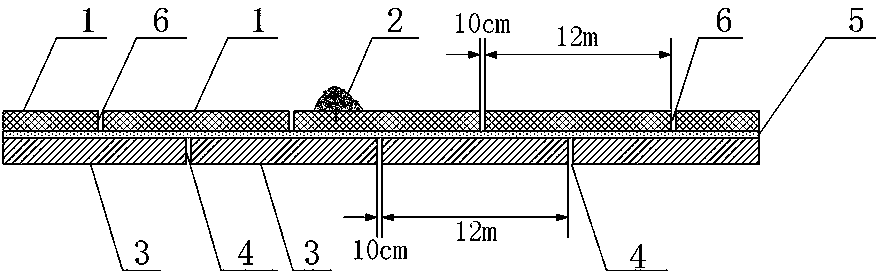

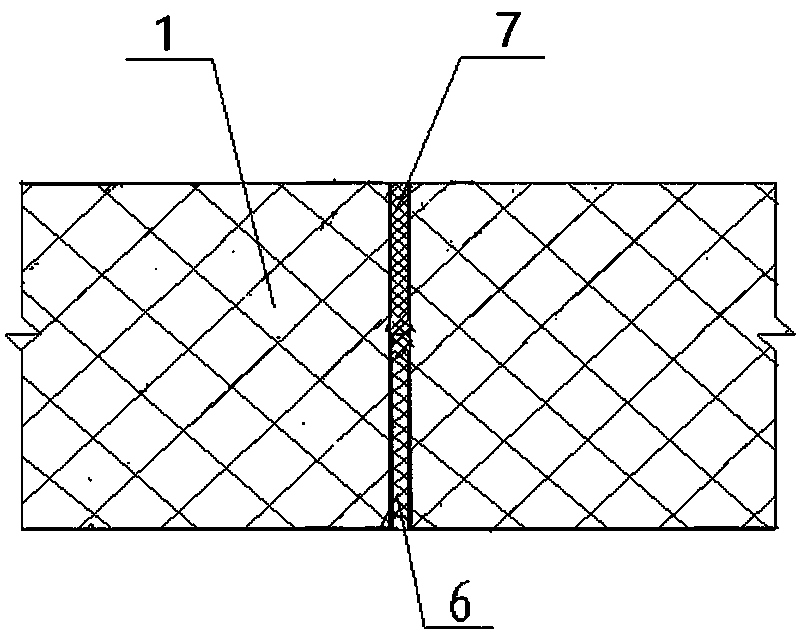

[0030] Combine below Figure 1-Figure 4 And embodiment the present invention is described further.

[0031] Such as Figure 1-Figure 4 As shown, this embodiment relates to a structure that improves the anti-seismic and shock-absorbing capacity of the tunnel lining. When the tunnel passes through the weak surrounding rock, if the construction is improper, the lining is prone to cracking, water seepage, primary branch invasion and even landslide accidents. After the landslide accident, the landslide body should be cleaned up in time, the collapse cavity should be backfilled, and the backfill body should be grouted and reinforced. However, no matter what backfilling method, backfilling material, grouting material and grouting amount are adopted, the strength, stiffness, joints, occurrence and other parameters of the surrounding rock in the collapse cavity cannot be restored to the original state of the surrounding rock, which also caused the surrounding rock The seismic inertia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com