Drilling Hydraulic Mining Underground Mining Robot

A technology for robots and mining wells, applied in the field of drilling, can solve the problems of large-scale promotion and application of drilling hydraulic mining technology, insufficient flowback of ore slurry, and difficulty in mining completion, so as to reduce drilling costs, improve production safety, The effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The principles and features of the present invention will be further described below in conjunction with the accompanying drawings. The examples given are only used to explain the present invention, not to limit the scope of application of the present invention.

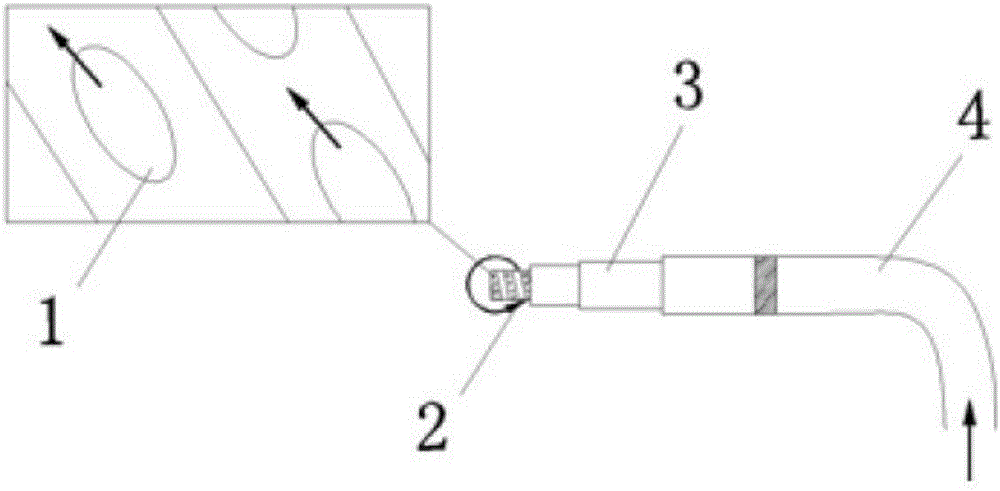

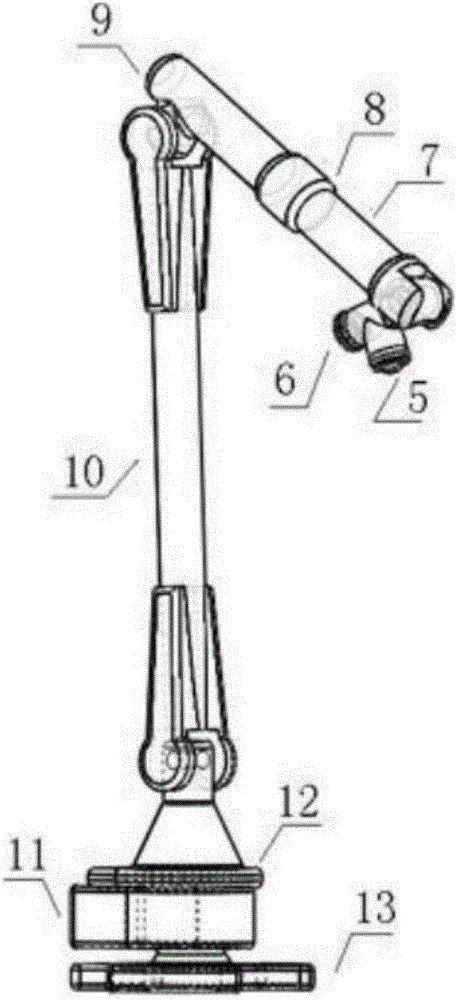

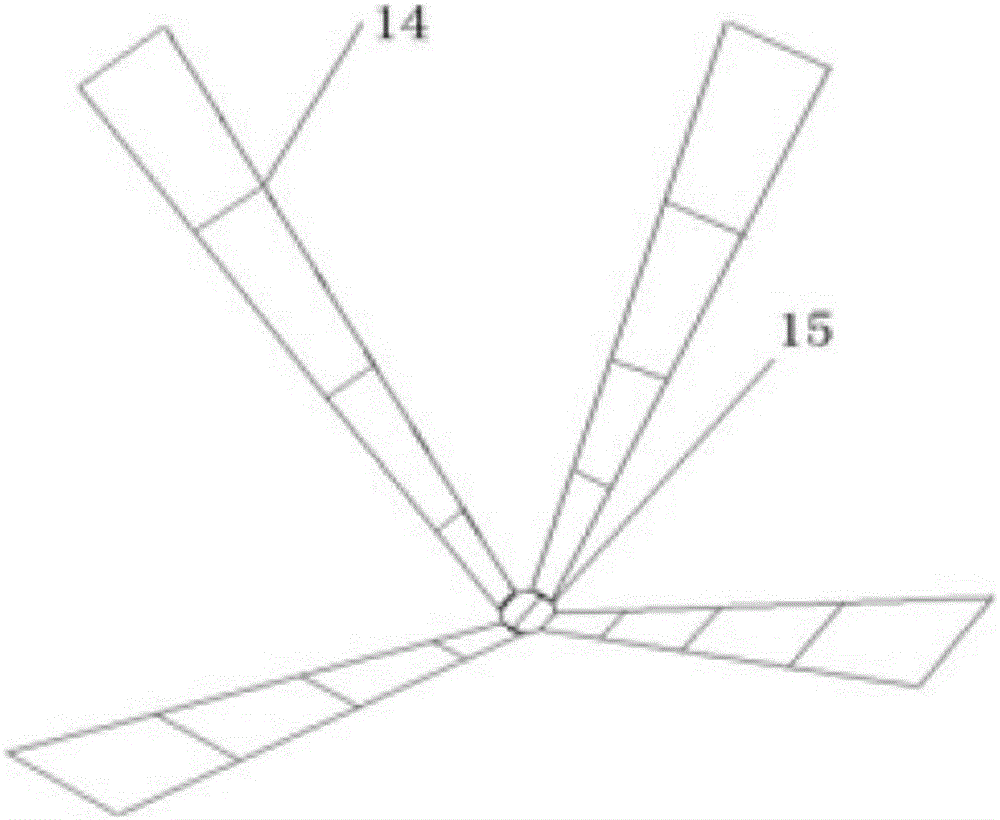

[0025] refer to Figure 1 to Figure 5 As shown, the drilling hydraulic mining underground mining robot of the present invention includes: a spiral hydraulic rotary nozzle 2, a telescopic support 3, a water supply hose 4, an infrared scanning device and a measuring device joint 5, a water supply hose joint 6, Hollow drill string 7, protective cover joint 8, drill pipe inner water pipe joint 9, crank rod 10, integrated electrical control box 11, 360° rotating support 12, mechanical arm base 13, foldable protective blade 14, mechanical arm Connector 15, mobile carrying platform 16, transmission wheel 17, toothed crawler belt 18, transmission shaft base 19, transmission shaft 20, spring shock absorber 21, hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com