A waste heat power generation device based on organic flash cycle on the side wall of aluminum electrolytic cell

An aluminum electrolytic cell and waste heat power generation technology, which is applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve the problems of low transformation risk, and achieve the effect of low transformation risk, good versatility and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better explain the present invention, the main content of the present invention is further clarified below in conjunction with specific examples, but the content of the invention is not limited to the following examples.

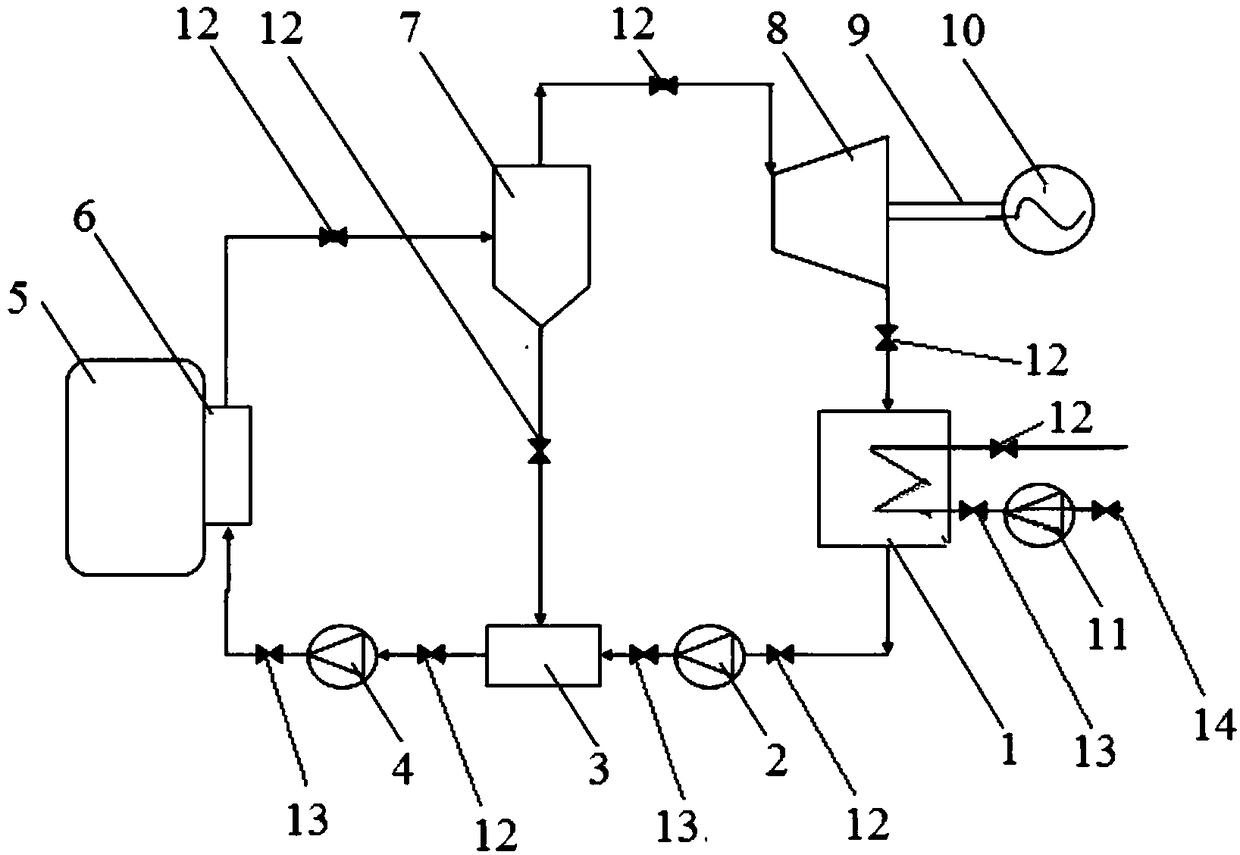

[0031] Such as figure 1 As shown, the aluminum electrolytic tank side wall waste heat power generation device based on the organic flash cycle of the present invention includes a condenser 1, a first working fluid pump 2, a mixer 3, a second working fluid pump 4, an aluminum electrolytic tank 5, a wall replacement Heater 6, evaporator 7, low boiling point working medium steam turbine 8, transmission shaft 9, generator set 10 and cooling water pump 11.

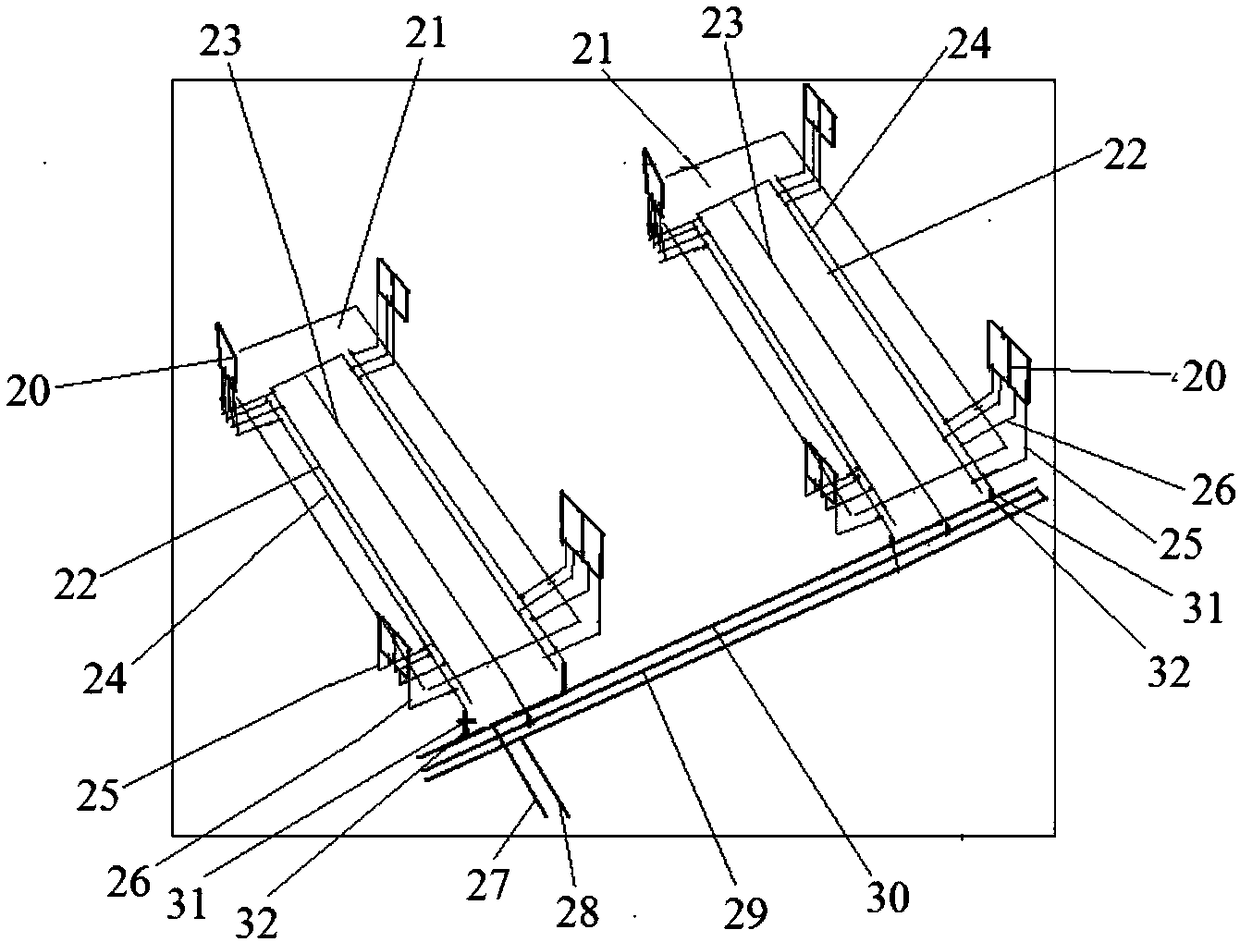

[0032] Wherein, the mixer 3 in this implementation is preferably a horizontal tank structure made of steel pressure-resistant material, such as Figure 5 As shown, the mixer 3 includes a mixer tank 39, a circulating liquid interface pipe 40 arranged on the upper right side of the mixer tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com