Self-repair re-molded multi-deformation thermosetting shape memory resin material and preparation method thereof

A resin material and self-healing technology, which is applied in the field of shape memory functional high-performance resin matrix, can solve the problems of micro-crack damage, inability to effectively realize complex shape deformation, memory resin cannot be reshaped, etc., and achieve stable shape memory performance , excellent heat resistance, the effect of many recovery cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]Dissolve 5g of bismaleimidodiphenylmethane (BMI) and 4g of 4,4'-diaminodiphenylsulfone in acetone in a cooling reflux device, and react at a controlled temperature of 60°C for 12 hours under stirring conditions , the solution was removed by rotary evaporation to remove the acetone solvent, and then vacuum-dried at 70° C. for 12 hours to obtain bismaleimide / aromatic diamine oligomer powder. Add the oligomer to 75g of epoxy resin (E-54), melt into a transparent solution at 100°C, add 4g of accelerator zinc acetylacetonate, stir for about 3 minutes, then add 12g of glutaric anhydride, stir quickly and mix well Finally, it is poured into a flat mold, and after vacuum defoaming at 110°C, it is treated according to the curing process 110°C / 1h+140°C / 8h+160°C / 2h, and the cured material is taken out after natural cooling.

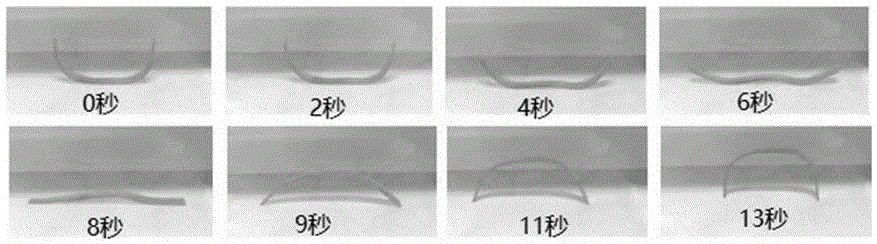

[0033] figure 1 It is a diagram of the transesterification reaction and crack repair mechanism. In the material of the present invention, under the condition...

Embodiment 2

[0040] Dissolve 13g of bismaleimidodiphenylmethane (BMI) and 9g of 4,4'-diaminodiphenylsulfone in acetone in a cooling reflux device, and react at a controlled temperature of 70°C for 12 hours under stirring conditions , the solution was removed by rotary evaporation to remove the acetone solvent, and then vacuum-dried at 70° C. for 12 hours to obtain bismaleimide / aromatic diamine oligomer powder. Add the oligomer to 100g of epoxy resin (E-51), melt into a transparent solution at 100°C, add 6.7g of accelerator zinc acetylacetonate, stir for about 3 minutes, then add 15g of glutaric anhydride, stir and mix quickly After uniformity, it is poured into a flat mold, and after vacuum defoaming at 110°C, it is treated according to the curing process 110°C / 1h+140°C / 8h+160°C / 2h, and the cured material is taken out after natural cooling.

[0041] Figure 4 is the shape memory cycle curve (DMA test) of the material of Example 2. The glass transition temperature of the prepared material...

Embodiment 3

[0044] After dissolving 25g of bismaleimide diphenyl ether and 18g of 4,4'-diaminodiphenyl ether in acetone in a cooling reflux device, under stirring conditions, the temperature was controlled at 70°C for 12 hours, and the After the acetone solvent was removed by rotary evaporation, the solution was vacuum-dried at 70° C. for 12 hours to obtain bismaleimide / aromatic diamine oligomer powder. Add the oligomer to 120g of novolac epoxy resin (F-51), melt it into a transparent solution at 100°C, add 8g of accelerator zinc acetylacetonate, stir for about 5 minutes, and then add 18g of hexahydrophthalo Acid anhydride, after stirring quickly and mixing evenly, pour it into a flat mold, after vacuum defoaming at 110°C, treat it according to the curing process 110°C / 1h+140°C / 8h+160°C / 2h, and take out the solidified material after natural cooling.

[0045] Figure 6 is the shape memory cycle curve (DMA test) of the above materials. The glass transition temperature of the prepared mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com