Cylindrical workpiece receiving device

A collection device and workpiece technology, which is applied to machine tools, manufacturing tools, conveyor objects, etc. designed for grinding the rotating surface of workpieces, can solve the problems of small application range, insufficient automation, complex structure of the collection device, etc. Easy to move and fix, wide application range, compact and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

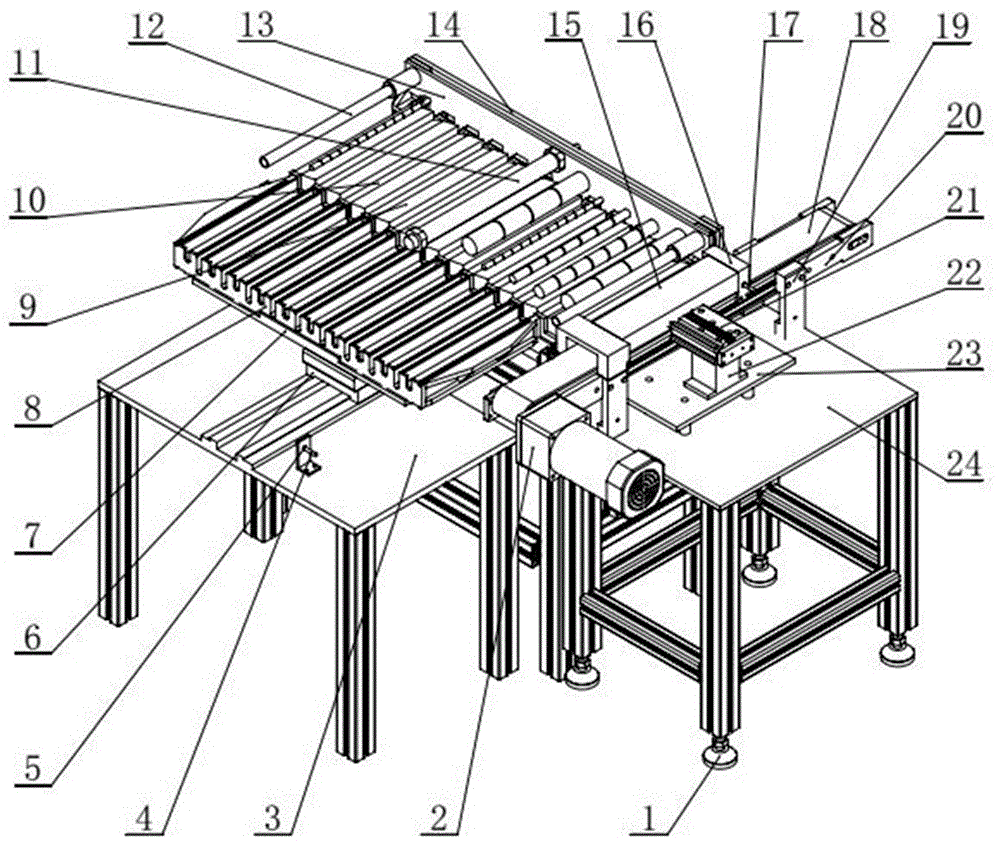

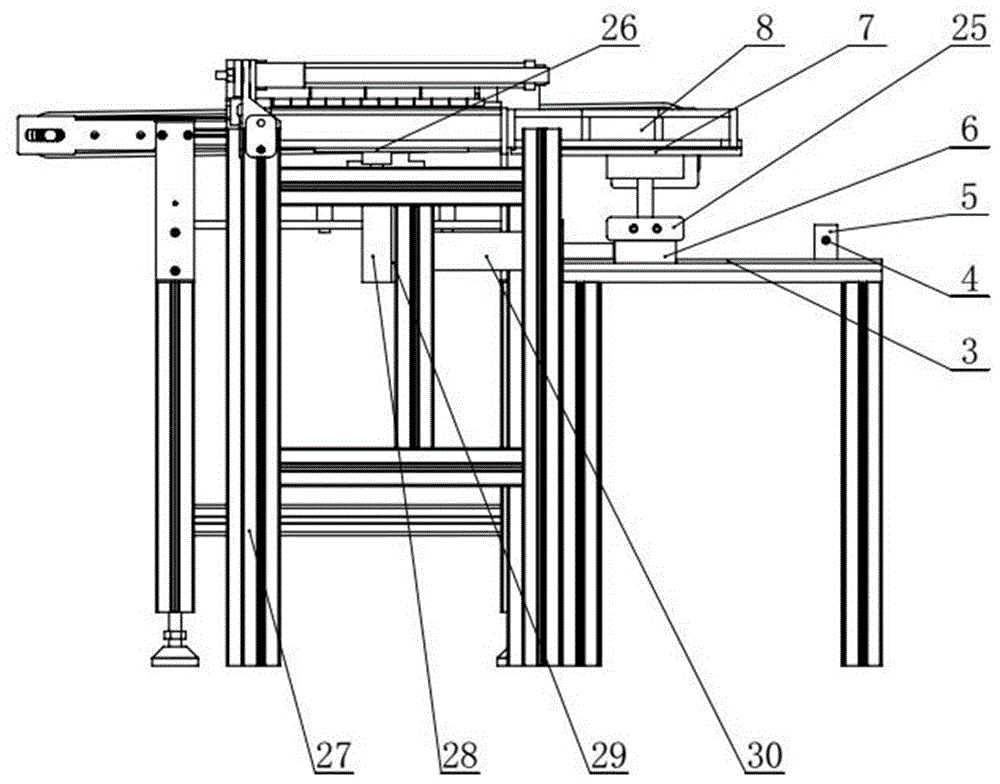

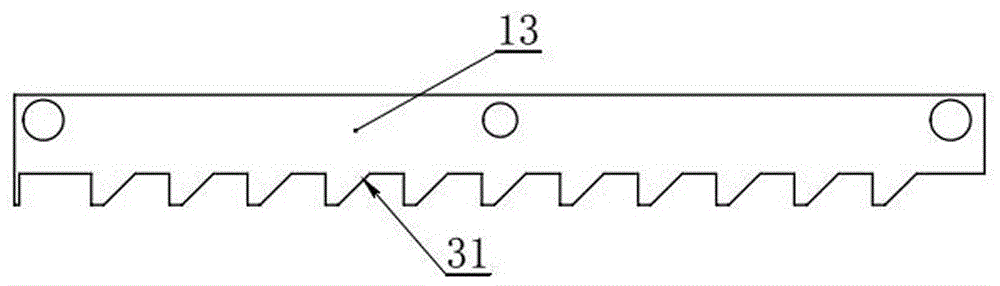

[0018] The specific implementation, structure, features and effects of the cylindrical workpiece receiving device according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0019] See attached figure 1 , 2 , 3, a cylindrical workpiece receiving device, comprising a machine platform 24, a material pushing box 15, a support 27, a material rack 10, a transverse slide seat 3 and a material receiving box 8, characterized in that: the boss 23 of the machine platform 24 A cylinder base 22 is installed, and a pusher cylinder I21 is installed on the cylinder base 22. The other end of the pusher cylinder I21 is equipped with a pusher box 15. The left end of the machine table 24 is installed with a flat belt base 20 through a support seat 19. The flat belt Base 20 is connected with material rack 10, and movable block 9 is placed on movable block base plate 26 by the movable block mouth of material rack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com