Method for operating an electric machine

A technology of operating parameters, operating phases, applied in motor vehicles, transportation and packaging, driver input parameters, etc., can solve problems such as wear, expensive dual-mass flywheels, limiting motor vehicle power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

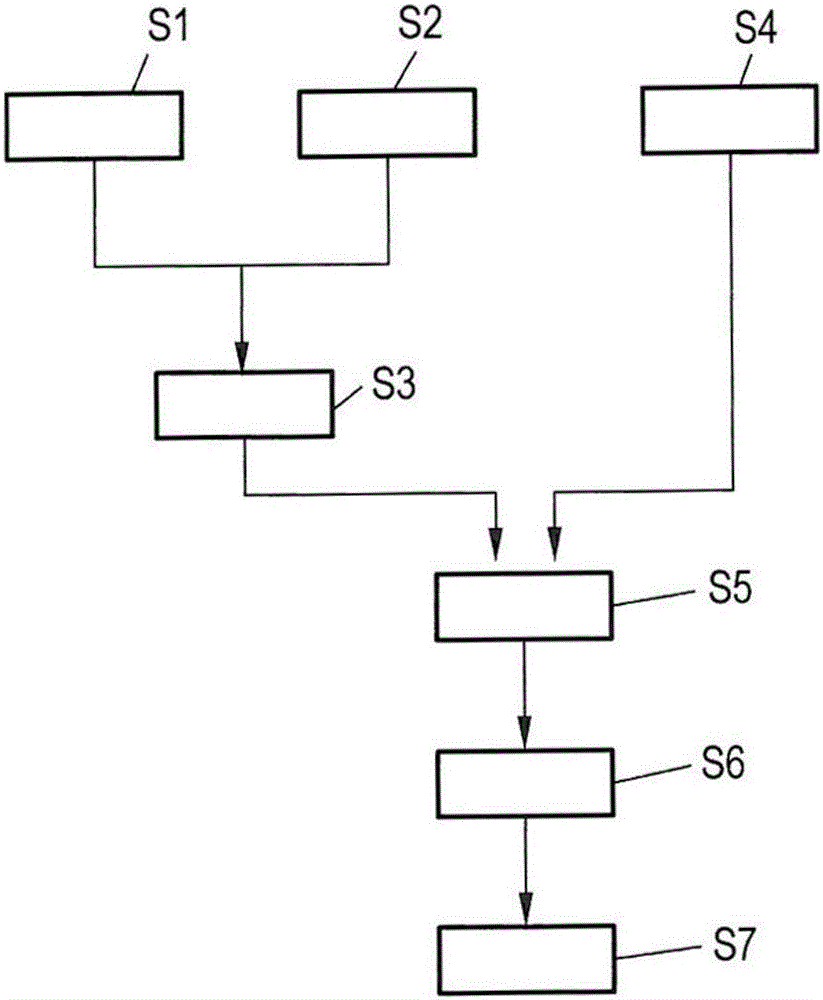

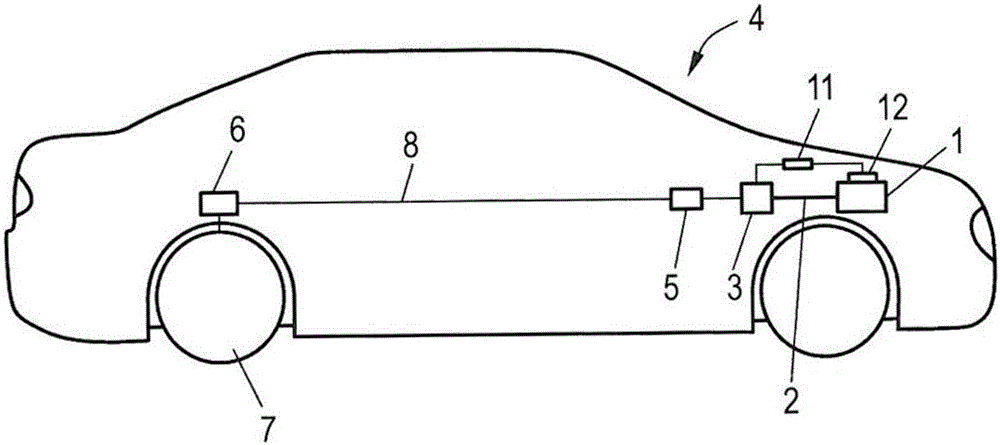

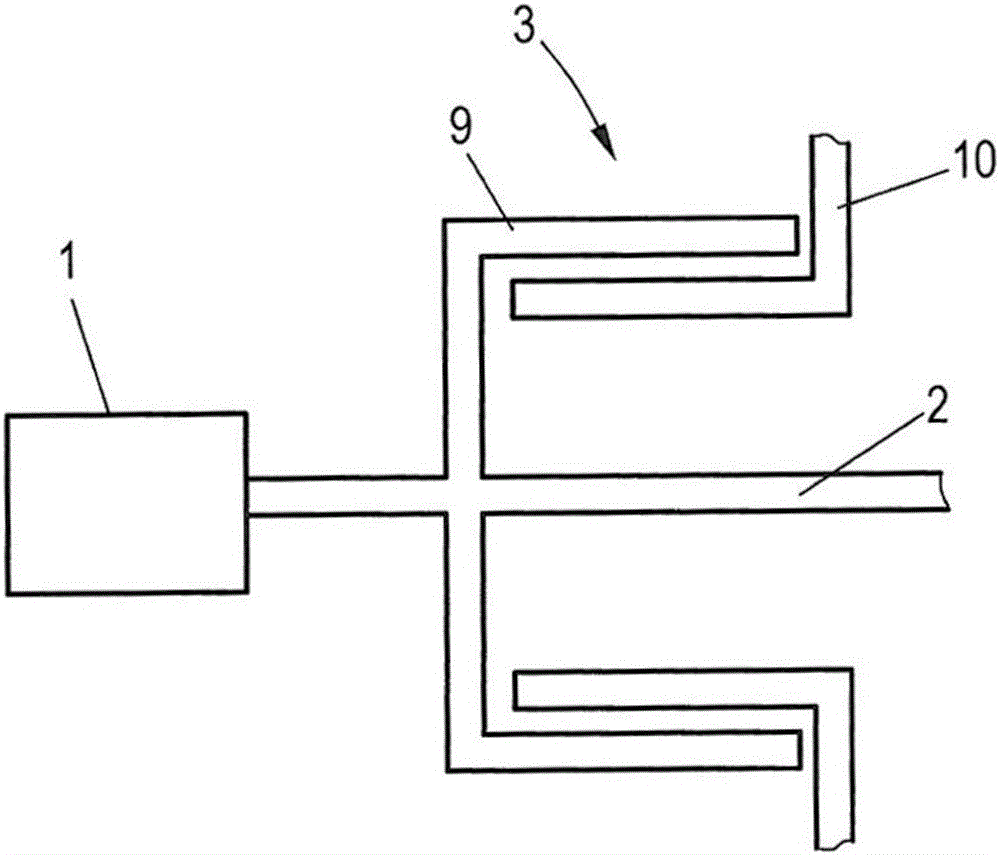

[0022] figure 1 A method for operating an electric machine coupled to an output shaft of a motor vehicle internal combustion engine is shown. The method refers to figure 2 and image 3 clarified, among which figure 2 A motor vehicle 4 is shown which comprises an internal combustion engine 1 , an output shaft 2 of the internal combustion engine 1 and an electric machine 3 coupled to the output shaft 2 . image 3 Detailed views of these components are shown.

[0023] Motor vehicle 4 is driven by internal combustion engine 1 , the torque of internal combustion engine 1 being conducted via output shaft 2 to transmission 5 , which transmits the torque to rear wheels 7 via differential 6 after transmission on layshaft 8 . The internal combustion engine 1 is a four-stroke engine, the torque of which fluctuates during the stroke of its cylinders. The cylinders of internal combustion engine 1 can supply torque to output shaft 2 only during their working strokes. During the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com