Printing system preventing organic gas from being discharged in printing

A printing system and organic gas technology, applied in general parts of printing machinery, printing machines, printing and other directions, can solve problems such as physical damage, air pollution, environmental damage, etc., to prevent volatilization, less irritating taste, and ensure good health. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

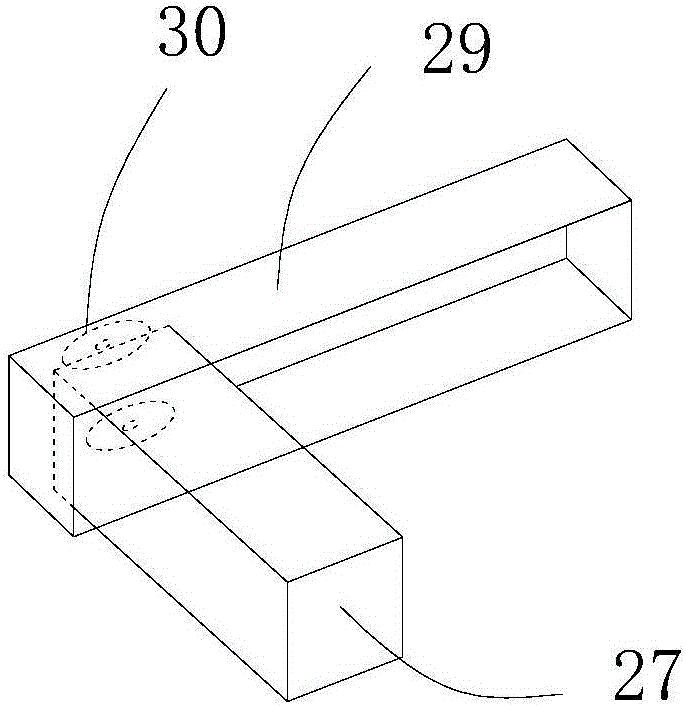

[0034] A printing system for preventing organic gas emissions during printing, comprising a printing box 1, a drying box 2 connected to the printing box 1, a cooling box 3 connected to the drying box 2, and a printing box 1 and a drying box 2 An exhaust fan 4 connected to the cooling box 3; the printing box 1 is provided with an inlet 5 and an outlet 6, and the printing box 1 is provided with a rotating shaft 7, a conveyor belt 8 arranged on the rotating shaft 7, and a printing substrate matched with the conveyor belt 8 Platform 9, a printing platen 10 matched with the printing platform 9 and a stripping mechanism 11 for peeling off the printed cardboard on the printing platform 9, the printing platform 9 is provided with a through hole 12, and the conveyor belt 8 placed on the top side of the rotating shaft 7 passes through Through the through hole 12 of the printing table 9; the drying box 2 is provided with a drying inlet 13 and a drying outlet 14, and the drying box 2 is pr...

Embodiment 2

[0036]A printing system for preventing organic gas emissions during printing, comprising a printing box 1, a drying box 2 connected to the printing box 1, a cooling box 3 connected to the drying box 2, and a printing box 1 and a drying box 2 An exhaust fan 4 connected to the cooling box 3; the printing box 1 is provided with an inlet 5 and an outlet 6, and the printing box 1 is provided with a rotating shaft 7, a conveyor belt 8 arranged on the rotating shaft 7, and a printing substrate matched with the conveyor belt 8 Platform 9, a printing platen 10 matched with the printing platform 9 and a stripping mechanism 11 for peeling off the printed cardboard on the printing platform 9, the printing platform 9 is provided with a through hole 12, and the conveyor belt 8 placed on the top side of the rotating shaft 7 passes through Through the through hole 12 of the printing table 9; the drying box 2 is provided with a drying inlet 13 and a drying outlet 14, and the drying box 2 is pro...

Embodiment 3

[0038] A printing system for preventing organic gas emissions during printing, comprising a printing box 1, a drying box 2 connected to the printing box 1, a cooling box 3 connected to the drying box 2, and a printing box 1 and a drying box 2 An exhaust fan 4 connected to the cooling box 3; the printing box 1 is provided with an inlet 5 and an outlet 6, and the printing box 1 is provided with a rotating shaft 7, a conveyor belt 8 arranged on the rotating shaft 7, and a printing substrate matched with the conveyor belt 8 Platform 9, a printing platen 10 matched with the printing platform 9 and a stripping mechanism 11 for peeling off the printed cardboard on the printing platform 9, the printing platform 9 is provided with a through hole 12, and the conveyor belt 8 placed on the top side of the rotating shaft 7 passes through Through the through hole 12 of the printing table 9; the drying box 2 is provided with a drying inlet 13 and a drying outlet 14, and the drying box 2 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com