Integrated tightening and riveting mechanism for steering gear adjusting nut and application method thereof

A technology for adjusting nuts and riveting mechanisms, which is applied in the field of parts assembly devices, can solve problems such as long working cycle, center deviation of riveting points, and slow manufacturing speed, and achieve the effects of improved product quality, compact mechanism, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

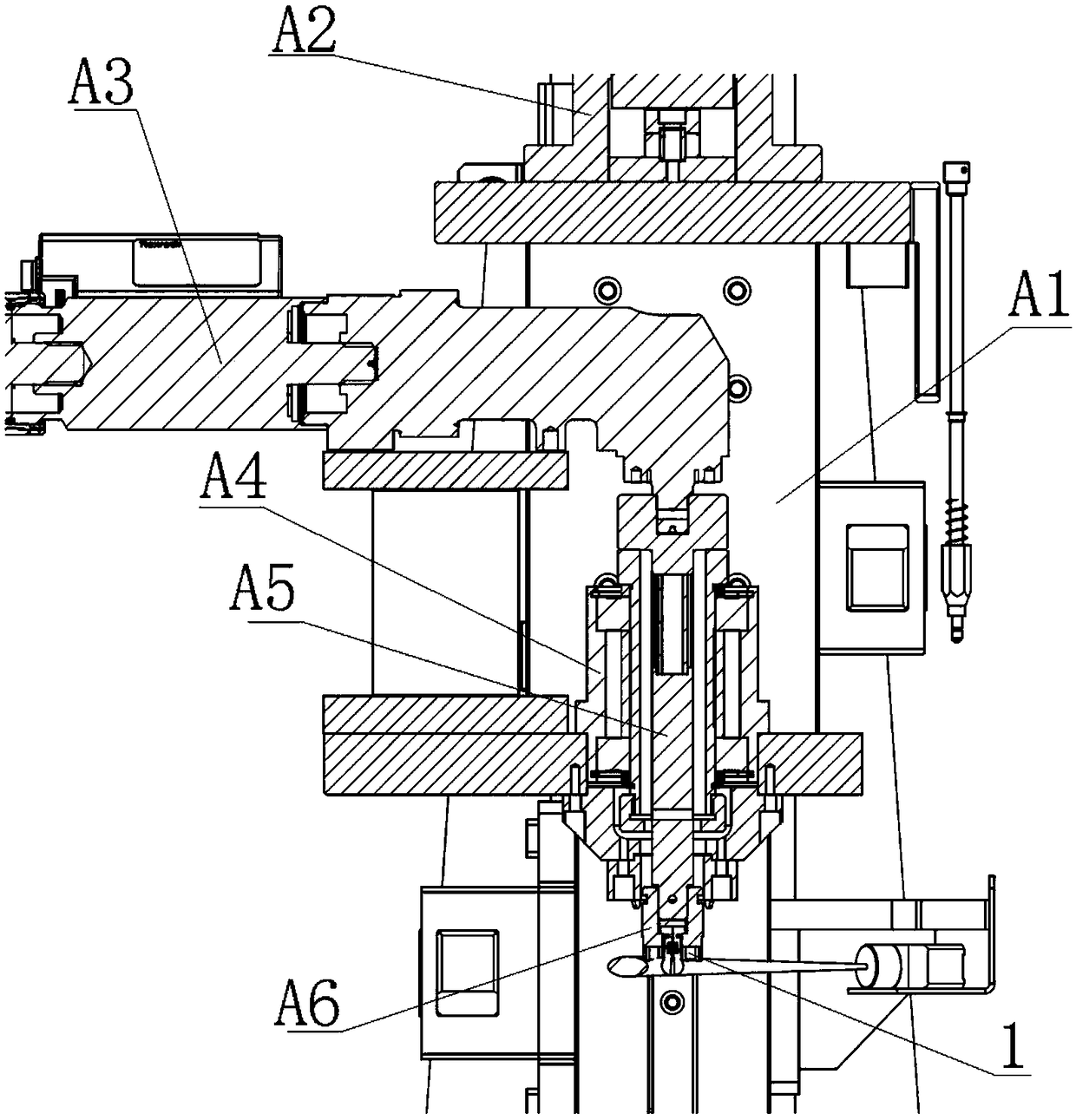

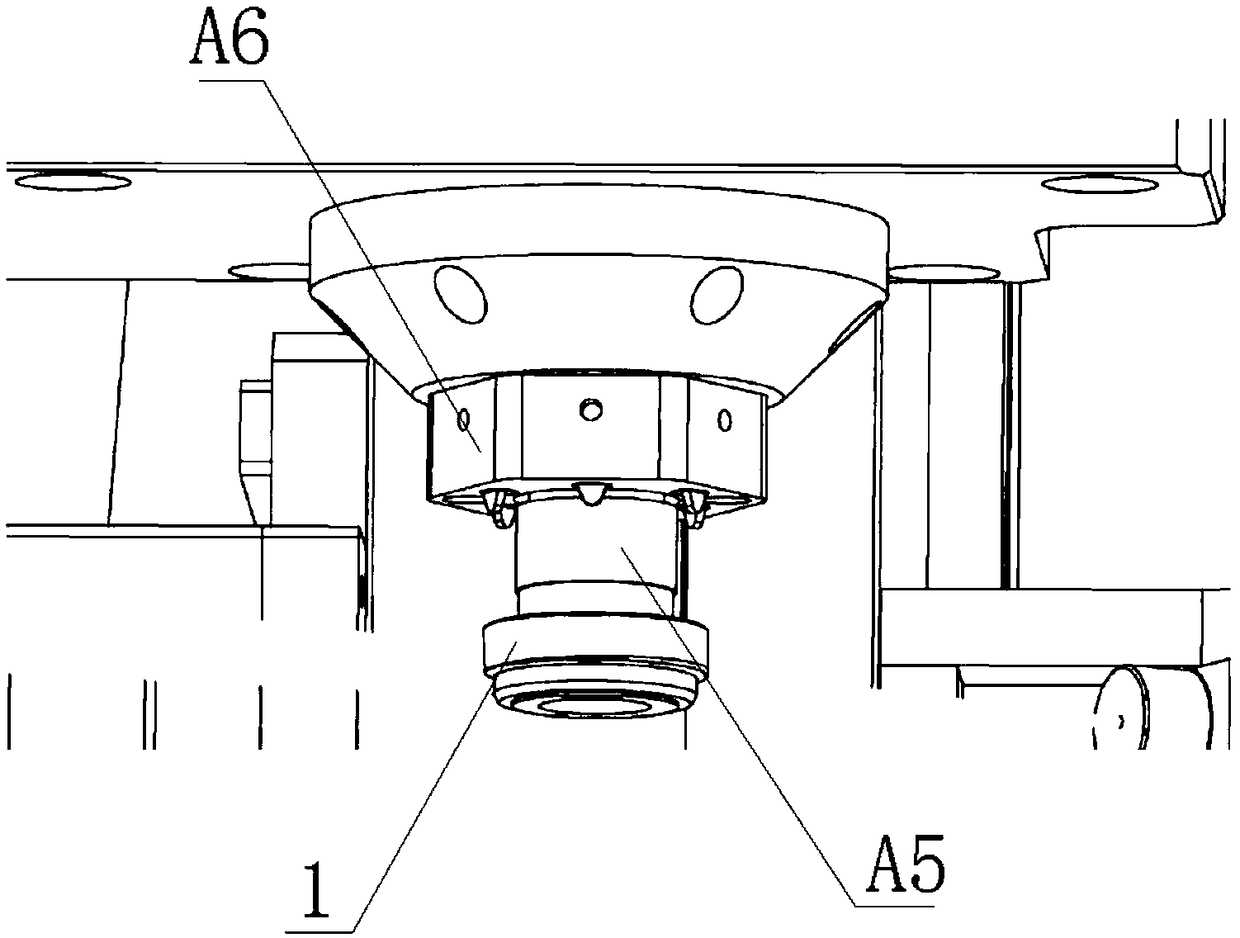

[0027] like Figure 1 to Figure 3 As shown in the figure, the steering gear adjustment nut adopts an integrated tightening and riveting mechanism, including an adjustment nut 1. The adjustment nut is set at the limit position of the machine tool where the set adjustment nut is screwed into the casing. The upper part of the adjustment nut is provided with an integrated Tightening and riveting mechanism component A;

[0028] The tightening axis and the riveting axis of the integrated tightening and riveting mechanism assembly A coincide on the same axis line, and the integrated tightening and riveting mechanism assembly can move up and down, and the adjustment nut arranged below it is tightened with the shell, and then tightened. Afterwards, the integral tightening and riveting mechanism components then riveted the adjusting nut.

[0029] The integrated tightening and riveting mechanism component A includes a C-type mechanism bracket A1, a gas-liquid hybrid booster cylinder A2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com