A laser rapid prototyping method for vertical metal thin-wall parts with complex surfaces

A laser rapid prototyping, complex surface technology, applied in the direction of process efficiency improvement, additive manufacturing, energy efficiency improvement, etc., can solve the problems affecting the surface quality of thin-walled formed parts, intermittent scanning paths, etc., to reduce equipment complexity, avoid Intermittent, improved surface quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The laser rapid prototyping method for vertical metal thin-wall parts with complex surfaces provided by the present invention will be further described below in conjunction with the accompanying drawings and a specific implementation example. In the embodiment, the selected laser rapid prototyping parameters are: laser power 1000W, scanning speed 6mm / s, powder feeding amount 3.6g / min; the powder used is 316L stainless steel powder; the substrate used is 316 stainless steel plate.

[0024] The method steps are as follows:

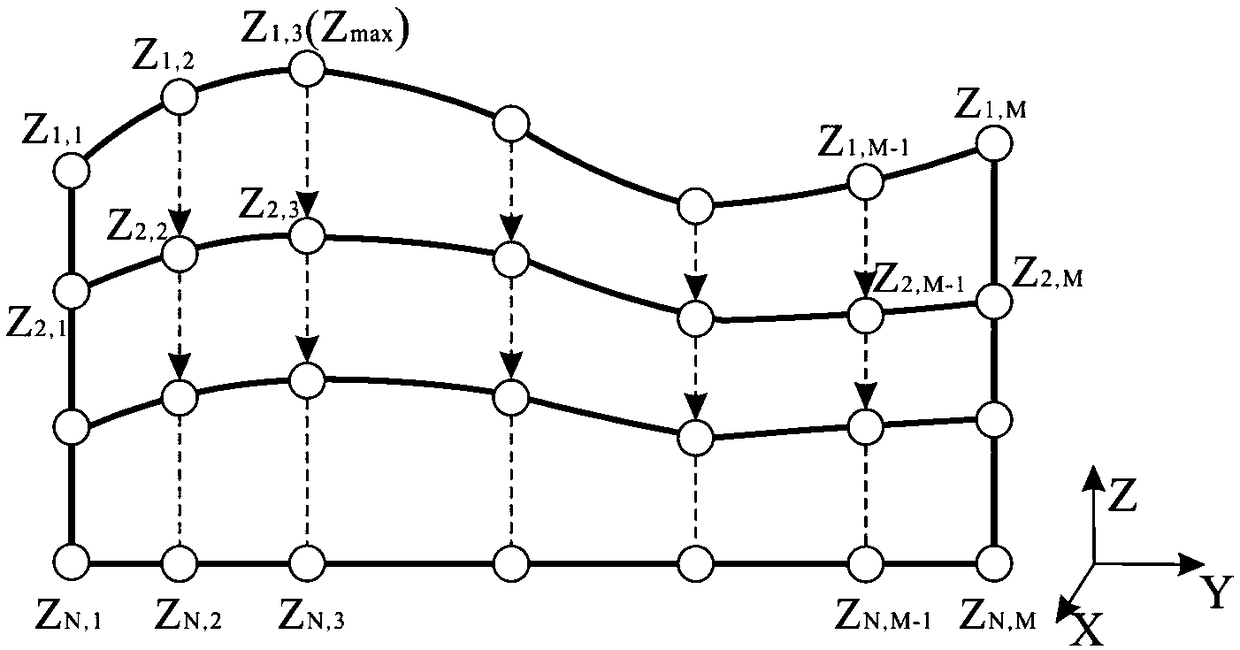

[0025] 1) The Y-direction length of the complex surface vertical metal thin-walled part to be formed is 94 mm. A three-dimensional solid model is established for the complex surface vertical metal thin-walled part to be formed. Considering the accuracy requirements and shape characteristics, the complex surface vertical metal thin-walled part is The upper surface of is divided into 94 points evenly, and the height values of these points are expresse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com