Heating type high-pressure vapor spray washer and a spraying method thereof

A heating and spray washing machine technology, which is applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, washing process, etc., which can solve the problem that the dirt is difficult to be cleaned, cleaned and the decontamination effect is not good. to achieve the best

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

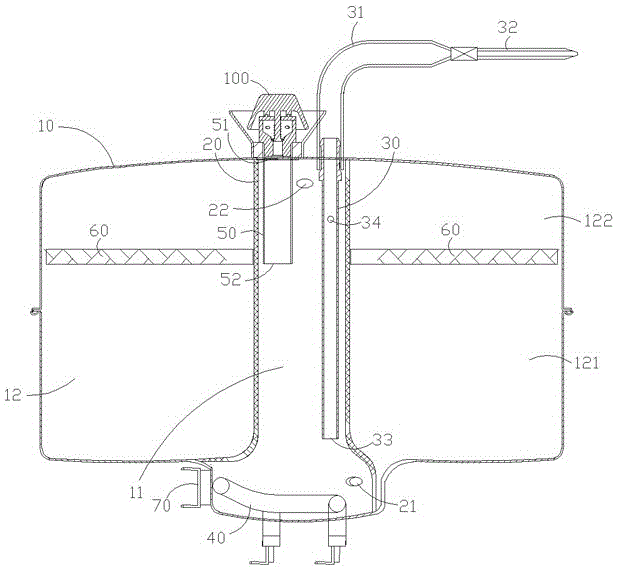

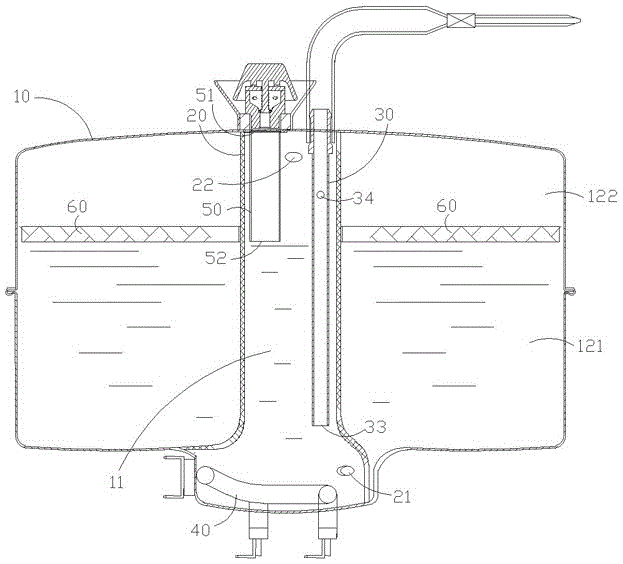

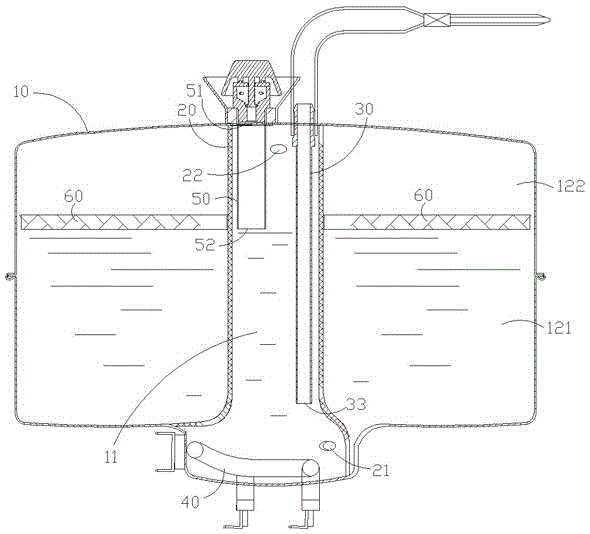

[0036] Such as Figures 1 to 9 As shown, a heating type high-pressure water vapor spray washing machine includes a boiler body 10, a heat insulation cover 20 and a water vapor output pipe 30, the boiler body 10 has a boiler cavity, and the heat insulation cover 20 is arranged in the boiler cavity , and the inner cavity of the boiler is divided into a heating chamber 11 and a water storage chamber 12 by means of the heat insulation jacket 20, wherein the water storage chamber 12 is formed by surrounding the inner surface of the boiler body 10 and the outer surface of the heat insulation jacket 20 , the heating cavity 11 is formed by surrounding the inner surface of the heat insulating sleeve 20 .

[0037] A water hole 21 and an air hole 22 are provided on the heat insulating cover 20, the water hole 21 is arranged at the bottom of the heat insulating cover 20, the air hole 22 is arranged at the top of the heat insulating cover 20, and the water hole 21 and the air hole 22 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com