Beancurd jelly discharging device for bean products

A soy product and cutting technology, which is applied in dairy products, cheese substitutes, applications, etc., can solve problems such as insufficient mixing, lagging, and incomplete cutting, and achieve complete crushing, speed up the feeding speed, and ensure the crushing rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

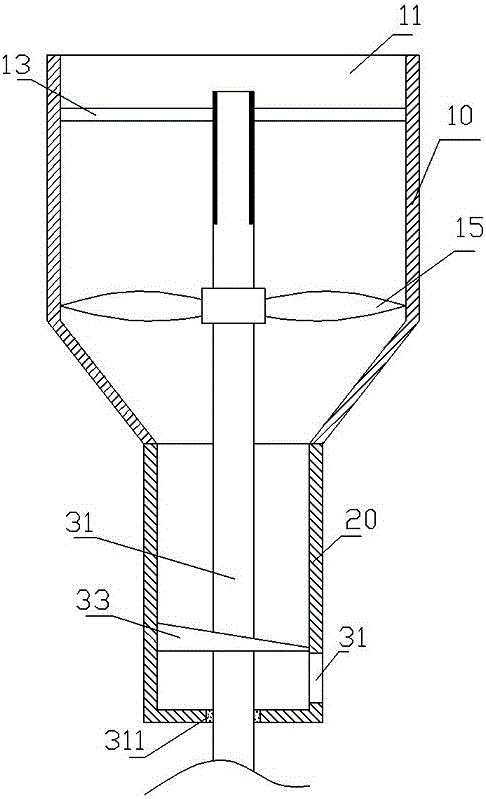

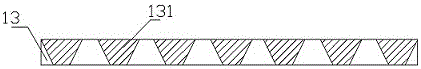

[0017] The reference numerals in the accompanying drawings of the description include: material storage cylinder 10, feed inlet 11, grid plate 13, grid bar 131, spiral blade 15, feeding channel 20, movable rod 31, sealing ring 311, feeding plate 33 .

[0018] Such as figure 1 The shown bean product lower brain device includes a material storage tube 10 with an inverted cone mechanism at the lower end, a feeding channel 20 and a driving mechanism. A feeding port 11 is provided above the material storage tube 10, and the driving mechanism includes a movable rod 31. The bottom of the movable rod 31 is connected with a cylinder, and the movable rod 31 passes through the feeding channel 20 and then extends into the material storage cylinder 10; the material storage cylinder 10 is connected with a grid plate 13, and the center of the grid plate 13 is provided with a threaded h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com