Label, method for manufacturing label, method for using label, and body with label

一种制造方法、粘合体的技术,应用在标签领域,能够解决难以分辨断裂面等问题,达到容易制造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

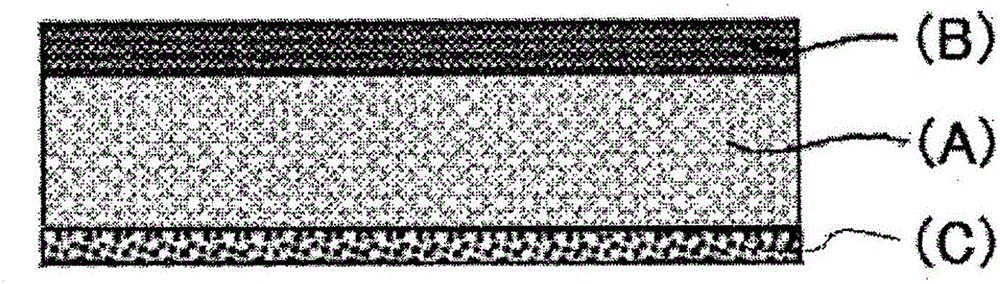

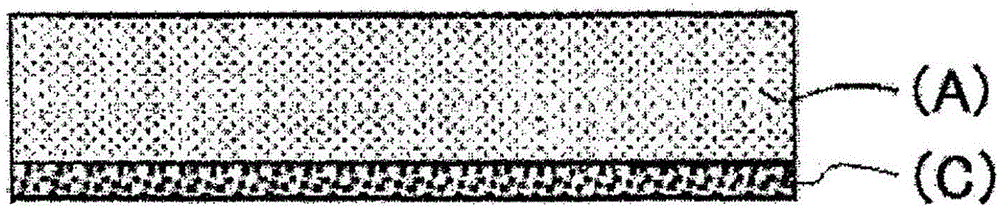

[0443] The resin composition b used as the base material layer (A) was melt-kneaded with an extruder set at 230° C., and then supplied to a T-die set at 250° C., from T The die is extruded into a sheet and cooled using a cooling device to obtain an unstretched sheet. This unstretched sheet was heated to 142° C., and stretched four times in the longitudinal direction by utilizing the difference in circumferential speed of the roll group to obtain a uniaxially stretched sheet.

[0444] In addition, resin composition e was used as the resin composition to be the surface layer (B), kneaded by an extruder set at 250° C., and then supplied to a T-die set at 250° C. Extrude into a sheet with a T-die, laminate one side of the uniaxially stretched sheet obtained in the step and cool to 60°C to obtain a base layer (A) / surface layer (B) (resin composition b / Two types of two-layer laminated sheets of resin composition e).

[0445] Next, heat the two double-layer laminated sheets obtain...

Embodiment 2~5

[0451] In Example 1, the heating temperature of the unstretched sheet to be the base material layer (A) was changed from 142°C to the temperature described in Table 2 when stretching the unstretched sheet in the longitudinal direction 4 times. Except that the heating temperature of the two-layer laminated sheet was changed from 148°C to the temperature listed in Table 2, in the same manner as in Example 1, the substrate layer (A) and The laminated film of each density of the surface layer (B), and using it, the labels of Examples 2-5 were obtained.

Embodiment 6

[0457] In Example 2, the T-die used for producing the unstretched sheet to be the base material layer (A) was set to two types of double-layer T-die, and the extruder set at 230° C. The resin composition b of the material layer (A1) (main layer) is melted and kneaded and extruded to a T-die. On the other hand, another extruder set at 230°C is used to form the base material layer (A2) The resin composition f (surface layer) was melt-kneaded and extruded to a T-die, and the two resin compositions were laminated in a T-die set at 250° C. Two kinds of double-layer unstretched sheets containing resin composition f and resin composition b were obtained in the same manner as in Example 2, except that the substrate layer (A1) / substrate layer (A2) / substrate layer (A2) / Three kinds of three-layer laminated films of the surface layer (B) (resin composition b / resin composition f / resin composition e) were obtained, and a label was obtained.

[0458] The overall thickness of the laminated ...

PUM

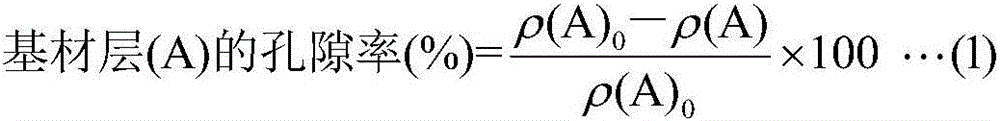

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com