Additive manufacturing using miscible materials

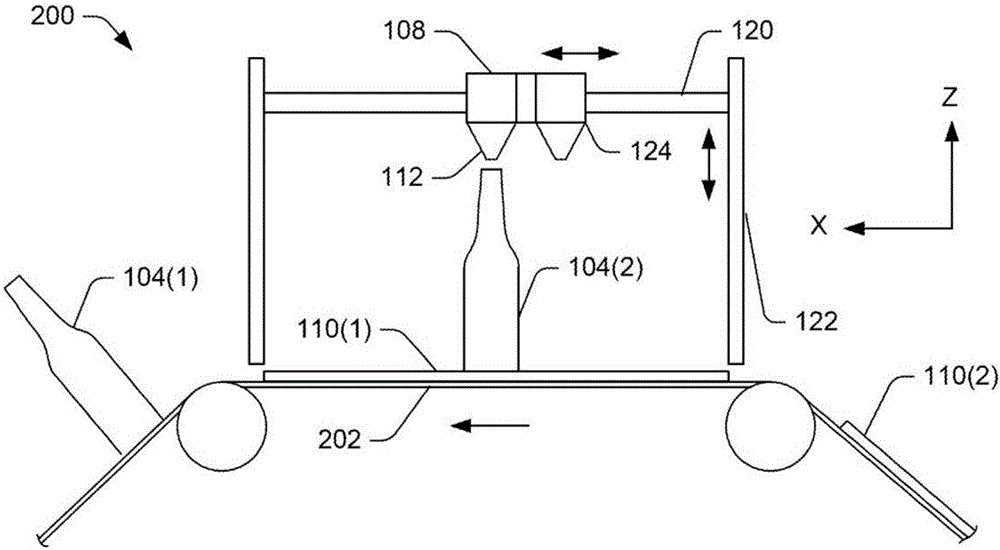

A technology for additive manufacturing and products, which is applied in the field of additive manufacturing using easy-to-mix materials, and can solve the problems of complex and difficult to implement additive manufacturing systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Figure 9 Shown is a first object portion 900 formed on a first substrate 902 and a second object portion 902 formed on a second substrate 906, which were formed using an extrusion-based additive manufacturing system. In this embodiment, the first and second body parts 900 and 904 are "pins", or cylindrical body parts, which are made using 3D printer formed. The first object portion 900 and the second object portion 904 each have a diameter of about 6 mm and a height of about 25 mm. The material used to form the first and second body parts 900 and 904 is the trade name TRITAN TM copolyester (specifically TRITAN TM TX1500HF copolyester), which is commercially available from Eastman Chemical Materials used to form the first and second substrates 902 and 906 are also TRITAN TM TX1500HF copolyester. Substrates 902 and 906 are made by incorporating the TRITAN TM TX1500HF copolyester is injection molded into the shape of bases 902 and 906, while first and second bo...

Embodiment 2

[0090] Figure 11 Shown is a first hexagonal vase 1100 formed using an additive manufacturing method, a second shorter hexagonal vase 1102 formed using an additive manufacturing method, a third hexagonal vase 1104 formed on a first substrate 1106 , and a fourth hexagonal vase 1108 formed on the second base 1110 , but not to the bottom of the fourth hexagonal vase 1108 . All four hexagonal vases 1100, 1102, 1104 and 1108 are under the trade name EASTAR (especially EASTAR TM 5011 PETG copolyester), a glycol-modified polyethylene terephthalate copolyester commercially available from Eastman Chemical In addition, hexagonal vases 1100, 1102, 1104 and 1108 are made with 3D printer formed, and for the build material in extrusion head 108 (i.e., EASTAR TM 5011 PETG copolyester) temperature is set at 240 ° C.

[0091] The first hexagonal vase 1100 is about 43mm high and 22mm in diameter, and the wall thickness is about 1mm. The frosted (opaque) look on the first hexagonal vase 1...

Embodiment 3

[0098] Figure 13 Object portion 1300 formed on substrate 1302 is shown, and a completed object 1304 comprising object portion 1300 and a portion of substrate 1302 is shown, wherein the completed object 1304 is shown attached to board 1306 . Figure 13 The photo on the left shows an object portion 1300 printed onto a substrate 1302 in the form of a tab 1308 with a raised tongue 1310 . Object part 1300 is an example of a functional object part 1300 that provides functionality (fixation) to the finished object 1304, such as Figure 13 Shown in the photo on the right. For example, a raised tab 1310 is shown inserted into a groove 1312 in the plate 1306 as an end cap for the plate 1306 . The material of construction used to form the object portion 1300 is the trade name SPECTAR TM (especially SPECTAR TM 14471 copolyester), a copolyester material of construction commercially available from Eastman Chemical The substrate 1302 dimension is approximately 2 mm thick and is the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com