Missile rudder surface control mechanism

A control mechanism and rudder surface technology, applied to self-propelled bombs, projectiles, offensive equipment, etc., to achieve the effect of improving space efficiency and reducing occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

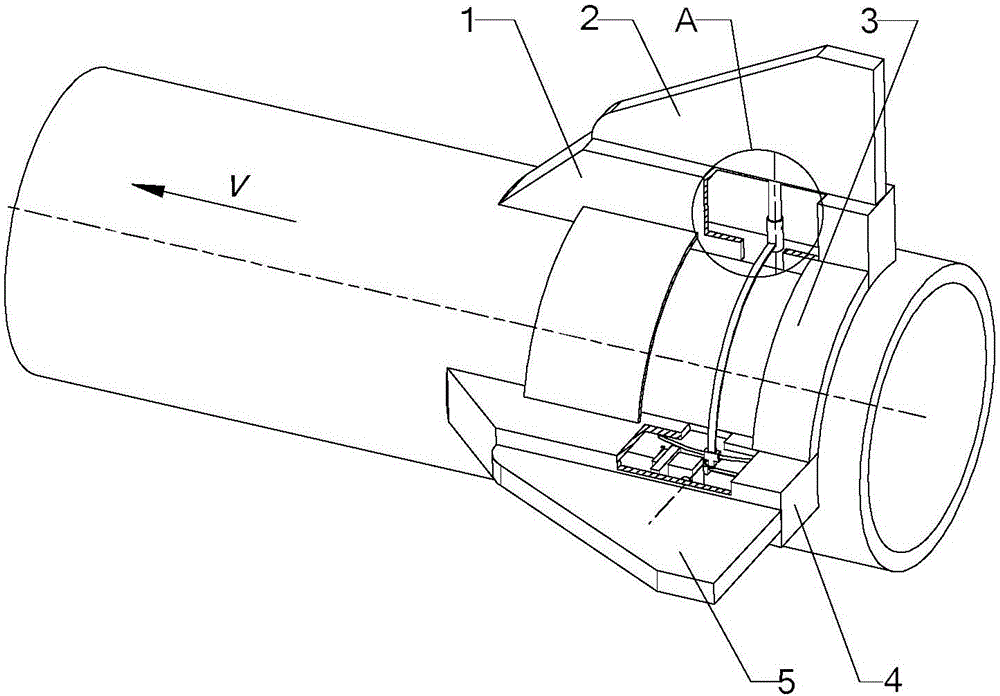

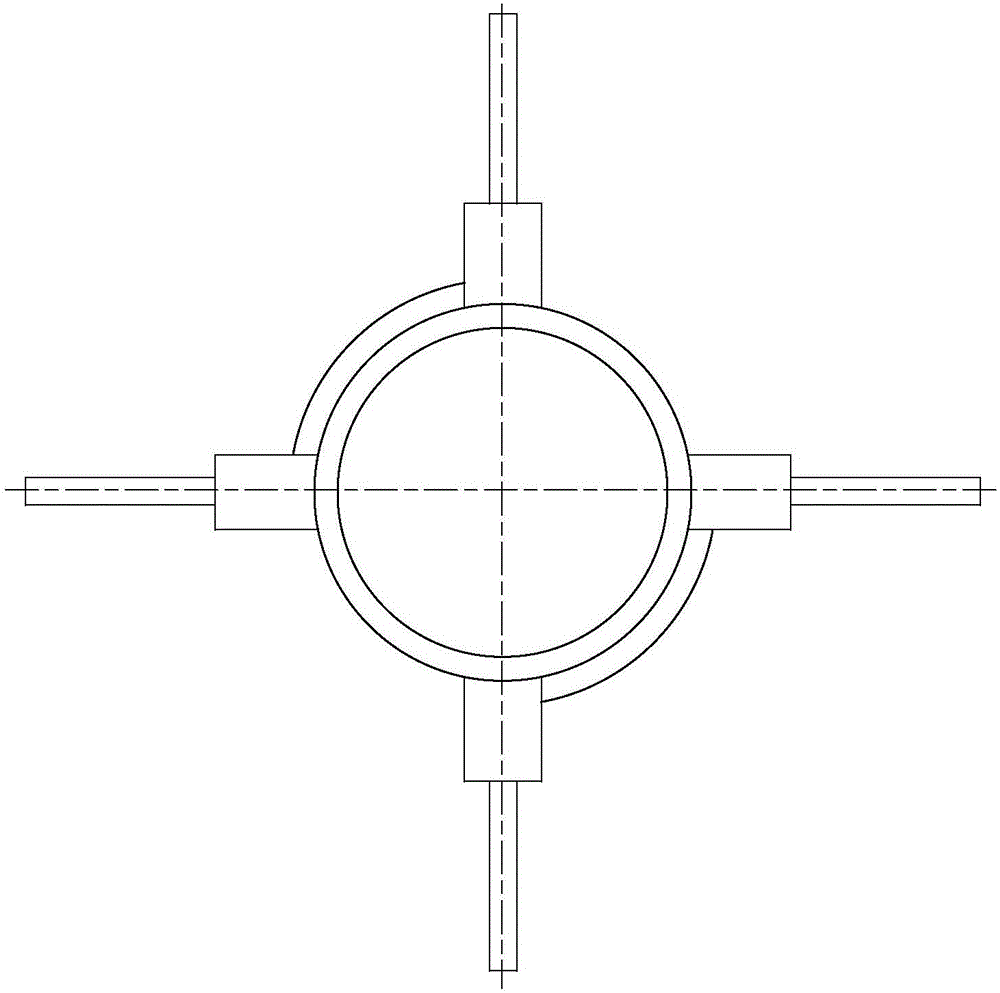

[0020] Such as Figure 1 to Figure 6 As shown, a missile rudder surface control mechanism includes a rudder cabin 1 and a rudder cabin 2 4; two rudder cabins 1 and two rudder cabins 4 are evenly distributed on the tail of the missile body along the circumference, and are fixed with the missile body Connection; two connecting cabins 3 are fastened to the body tail, and the two ends of each connecting cabin 3 are respectively fixedly connected with a rudder cabin 1 and a rudder cabin 2 4; 4 is connected with two rudders 5; each rudder one 2 is connected with a corresponding rudder cabin two 4 by a connecting rod one 6. figure 1 Among them, V is the running speed of the projectile.

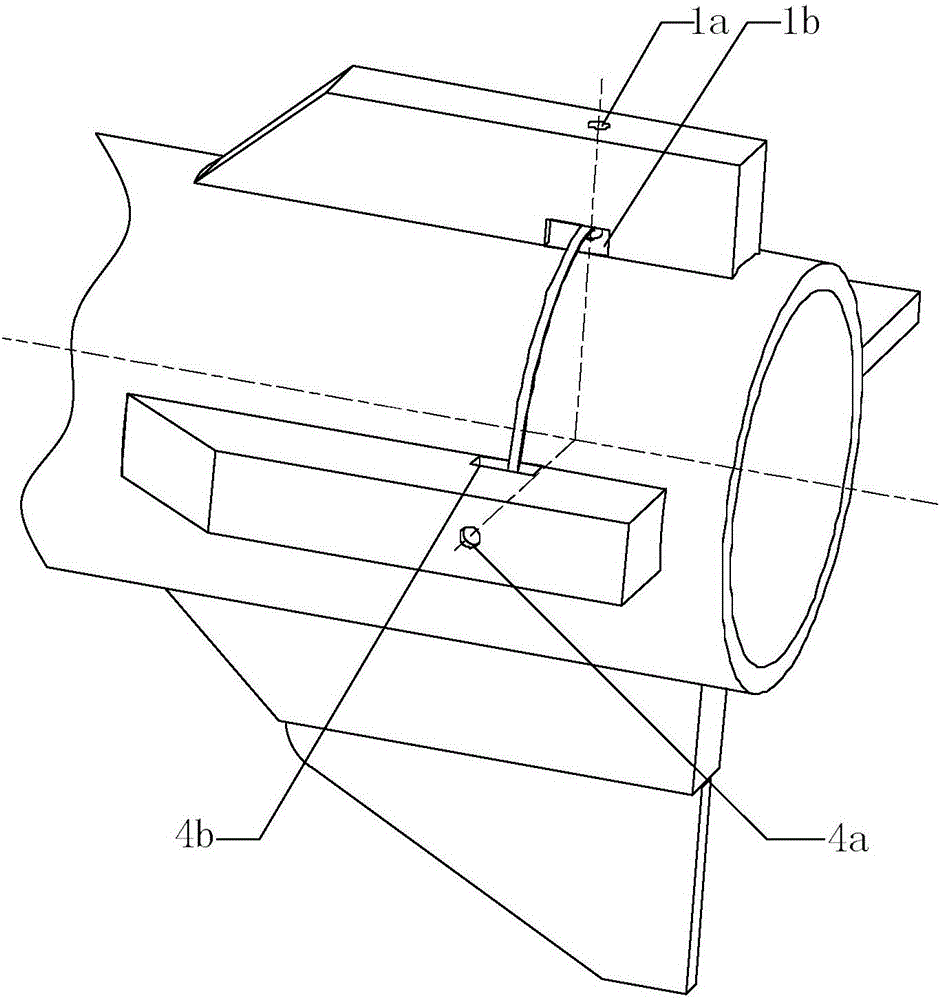

[0021] Such as Figure 4 and 5 As shown, the rudder shaft-2a fixed on the rudder-2 passes through the bushing 6d fixed at one end of the connecting rod-6, and forms a revo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com