Umbrella skirt type cement-based composite insulated cross arm and manufacturing technology thereof

A technology of composite insulation and insulating cross-arm, applied in the direction of building types, buildings, towers, etc., can solve the problems of increasing the area of transmission corridors, increasing the height of iron towers and steel consumption, and increasing the operating cost of transmission lines, so as to reduce engineering demolition Cost, reduce the height of the tower, reduce the effect of line corridor distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

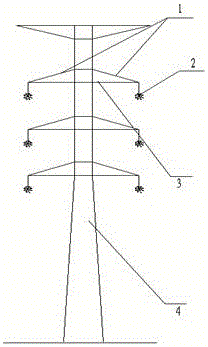

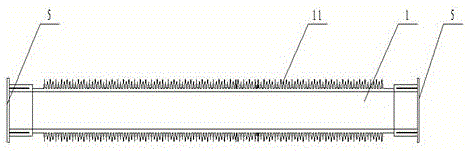

[0024] see figure 1 with figure 2 , the embodiment of the present invention includes:

[0025] An umbrella skirt type cement-based composite insulating cross-arm, the insulating cross-arm has a triangular shape structure, which is formed by connecting three cement-based composite insulating parts 1 and three rigid parts 3 through flanges 5, the cement-based composite The insulating part 1 is made by one-time molding process of centrifugal method, which makes full use of the good insulating properties and high-strength mechanical properties of cement-based composite materials, so that the insulating cross-arm takes on the two functions of electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com