Method for erecting precast beam of super-wide bridge deck at narrow space by using high-low leg gantry crane

A technology of prefabricated beams and leg doors, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., to achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation manner of the present invention will be further described below in combination with specific examples.

[0031] The present invention is aimed at the difficult point of the prefabricated beam transportation and erection method, and the measures are:

[0032] (1) Determine the foundation of the door crane according to the topography and geological conditions of the site, and strictly control the quality of the foundation.

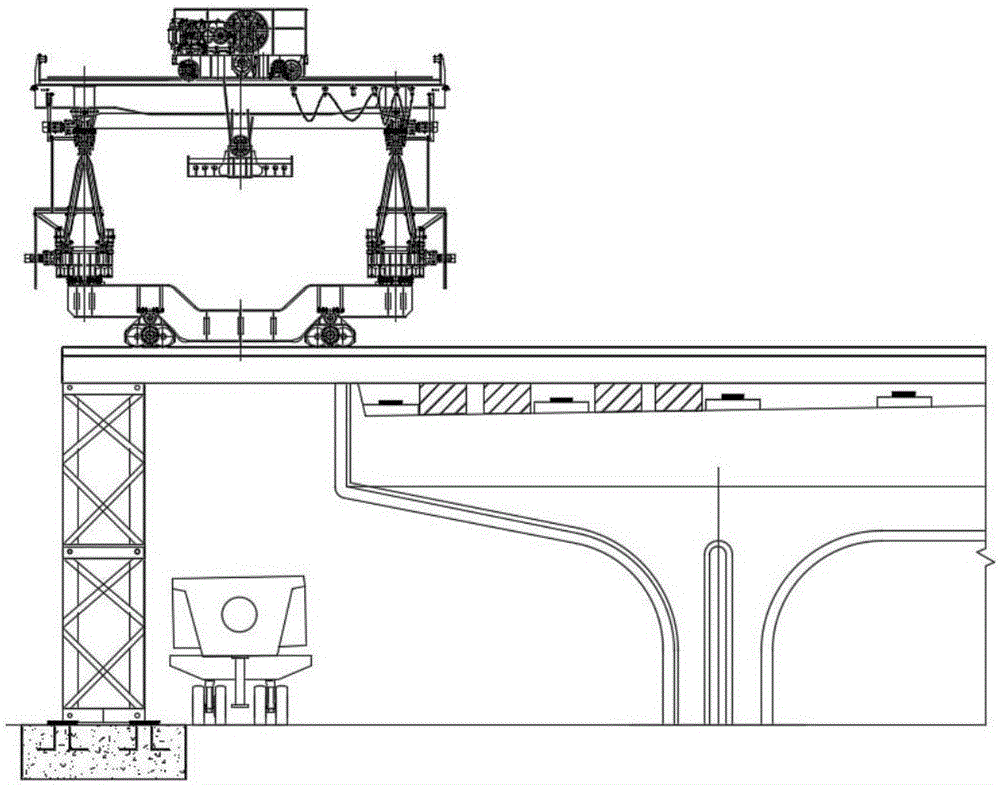

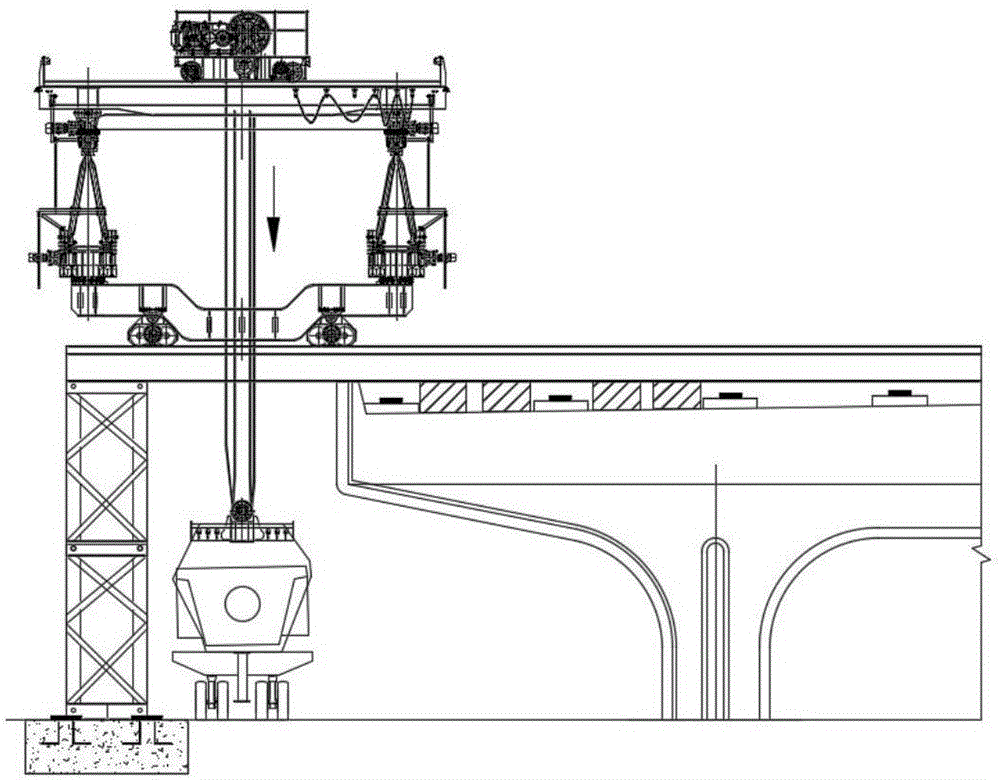

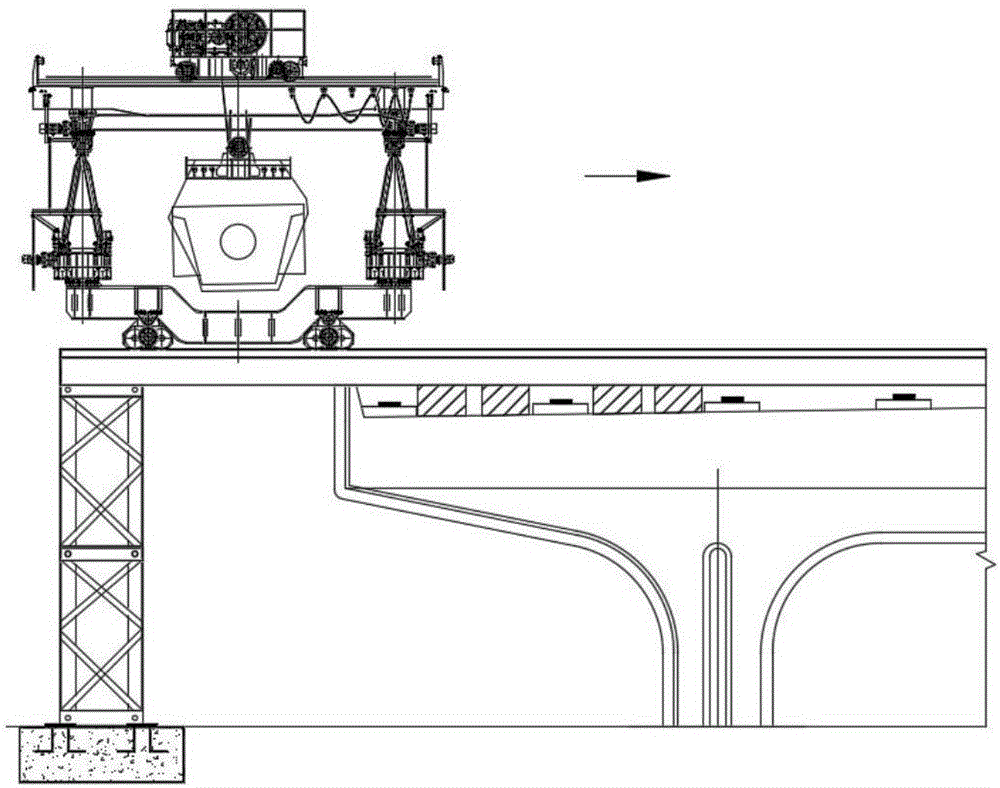

[0033] (2) The height and load of the outriggers of the gantry crane are calculated according to the actual situation and processed accurately, and the elevation of the combination (outrigger + traversing track, outrigger of the gantry crane + beam of the gantry crane) matches the elevation of the bridge deck.

[0034] (3) Accurately install the outriggers of the door crane and the traversing track to meet the space in the passageway between the lifting beam of the bridge erecting machine and the beam transporting vehicle, and ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com