Coated pigment composition and production method thereof

A technology for a pigment composition and a manufacturing method, applied in the directions of organic dyes, inks, household appliances, etc., can solve the problems of reduced color concentration and insufficient resolubility, and achieve the effects of high color concentration and high resolubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

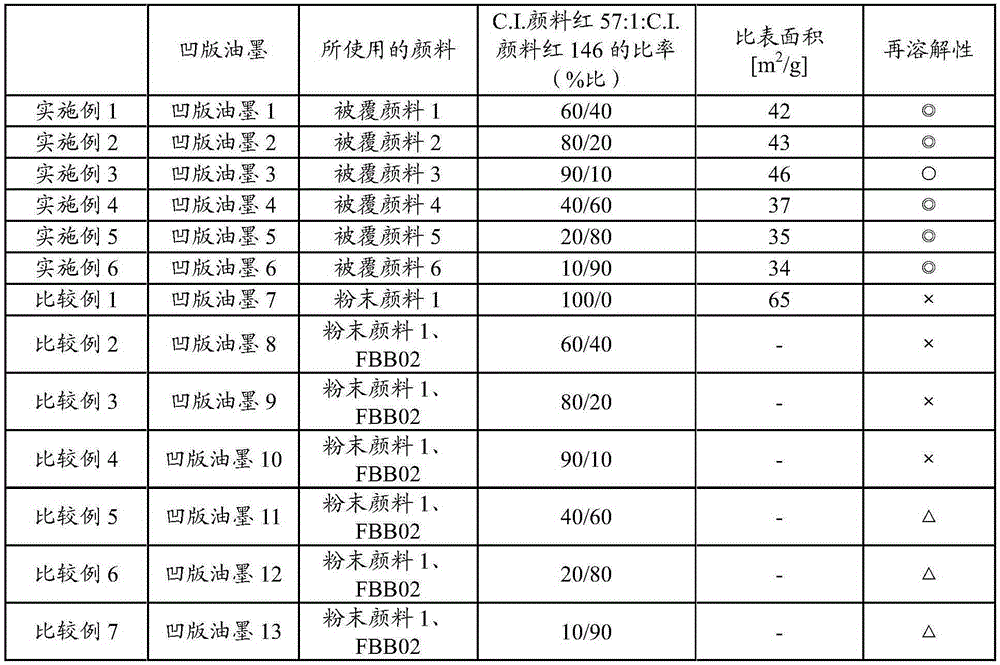

Examples

Embodiment 1

[0088] 9.0 parts of coated pigment 1 obtained in Production Example 3, 14.0 parts of toluene-free polyurethane resin (Sanprene IB-501, manufactured by Sanyo Chemical Industry Co., Ltd.), 1.5 parts of vinyl chloride- Chlorovinyl acetate resin of vinyl acetate copolymer, 3 parts of methyl ethyl ketone, 3 parts of ethyl acetate, 14 parts of propyl acetate, 2 parts of isopropanol, 180 parts of 3mmφ steel balls, with a paint conditioner (Toyo Seiki Co., Ltd.) was dispersed for 60 minutes to obtain a pigment dispersion liquid. Further, 16 parts of toluene-free polyurethane resin (Sanprene IB-501, manufactured by Sanyo Chemical Industry Co., Ltd.), 33 parts of propyl acetate, and 4.5 parts of isopropanol were added to the pigment dispersion, and dispersed for 5 minutes with a paint conditioner. , to obtain gravure ink 1.

Embodiment 2

[0090] In the operation of Example 1, except that the coated pigment 1 was changed to the coated pigment 2, the same operation as in Example 1 was carried out, and the gravure ink 2 was obtained.

Embodiment 3

[0092] In the operation of Example 1, except that the coated pigment 1 was changed to the coated pigment 3, the same operation as in Example 1 was carried out, and the gravure ink 3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com