Turnover and material collection equipment with flattening function

A technology of function and equipment, which is applied in the field of flipping and feeding equipment, can solve the problems of not having the flipping function and flattening the cardboard, the tray cannot realize continuous feeding, and the tray does not have the lifting function, so as to achieve a simple mechanism and realize the flipping effect , good flip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

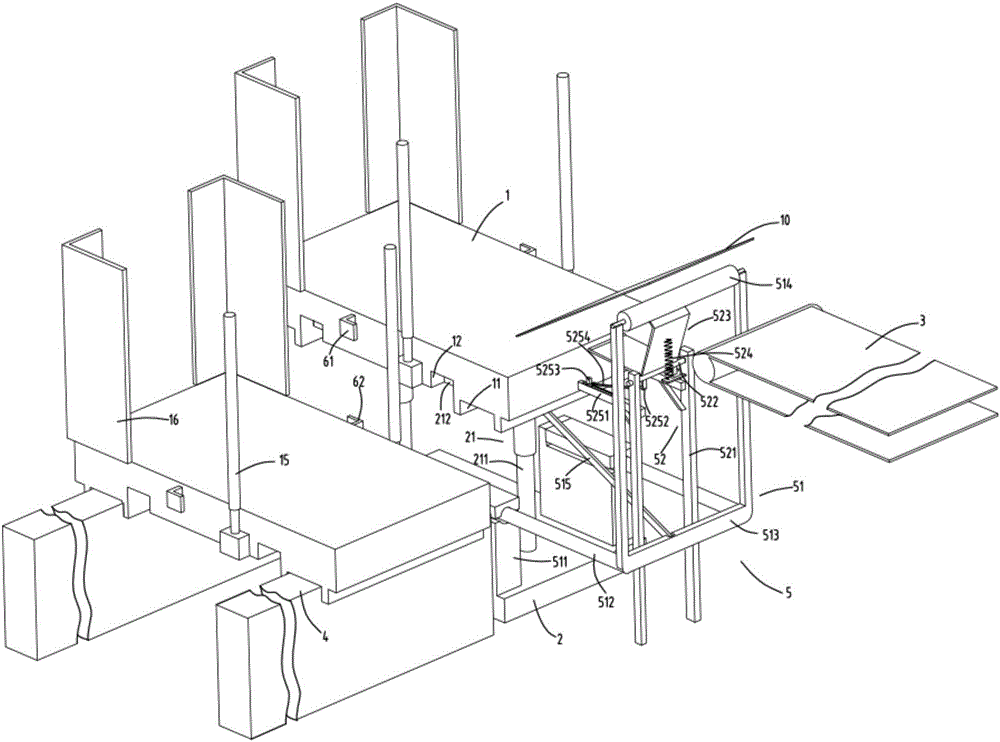

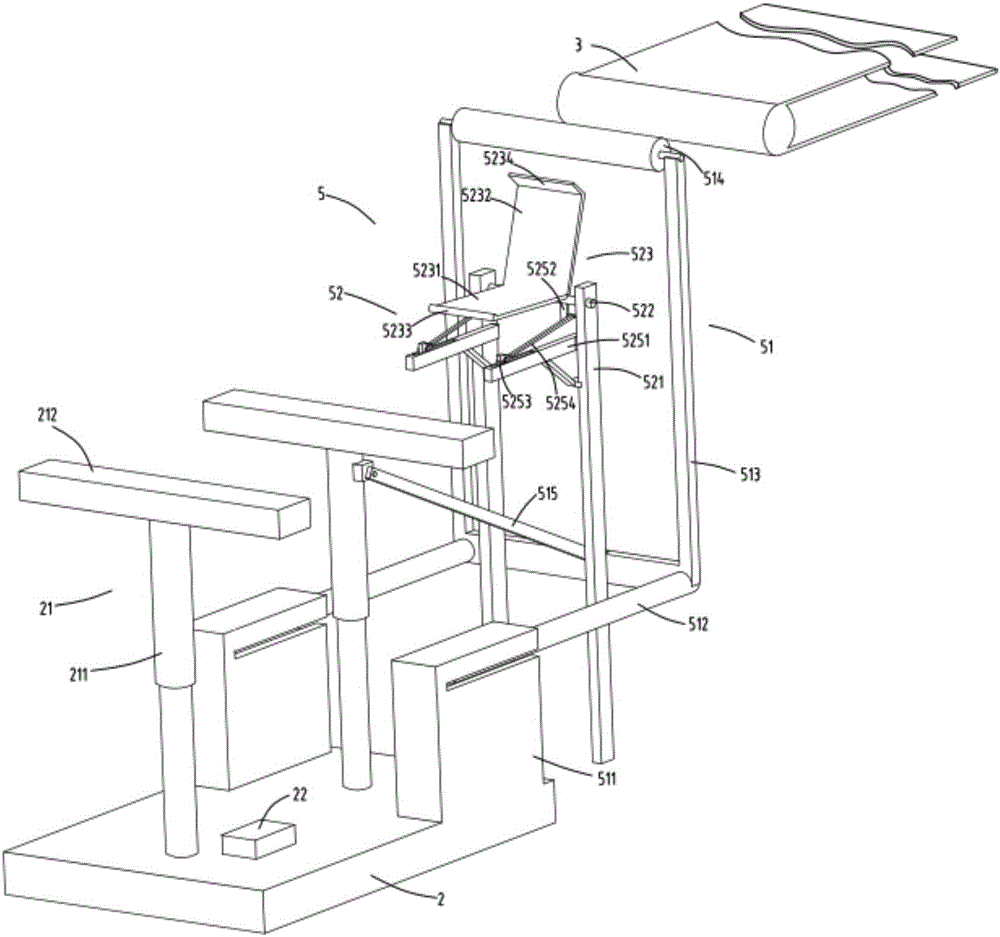

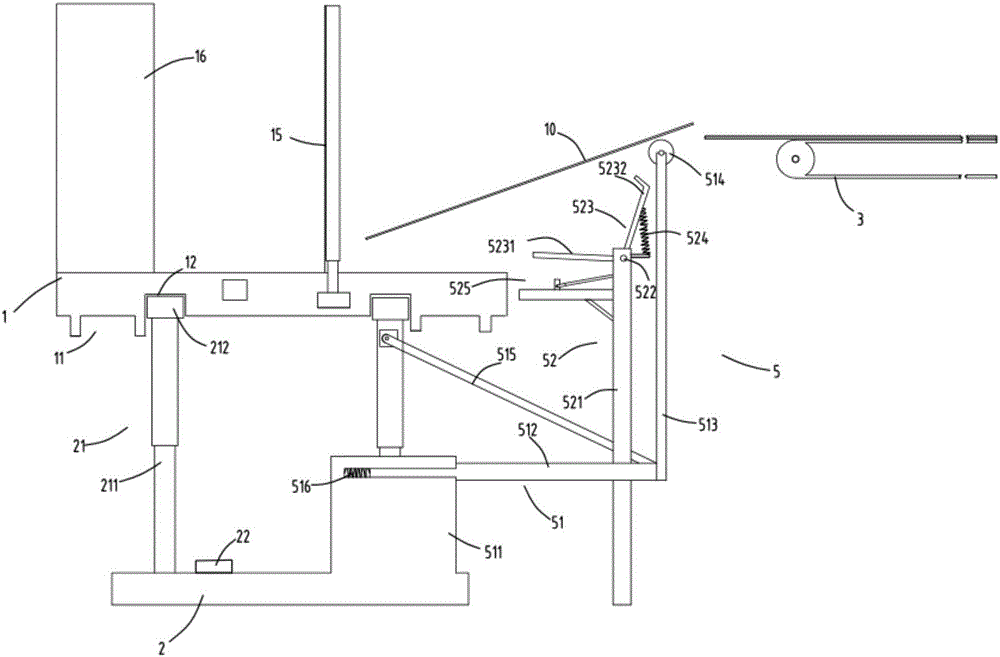

[0036] figure 1 It is a schematic diagram of the structure of the turning and receiving equipment with the function of pushing flat. figure 2 It is a schematic diagram of the structure of the base and the turning device, image 3 It is a schematic diagram of the front view when the tray of the flipping material receiving equipment with push-flat function starts to receive materials, Figure 4 It is a schematic diagram of the front view when the tray of the flipping material receiving equipment with push-flat function starts to receive a certain amount of material, Figure 5 It is a schematic diagram of the front view when the leveling device starts to flatten the cardboard when the pallet is turned over and spliced by the flipping and splicing equipment with the function of pushing flat. Figure 6 is a schematic diagram of the structure of the flip frame, Figure 7 It is a schematic diagram of the position relationship between a pallet full of material and the next palle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com