Factorial construction technology for small prefabricated components

A construction process and technology for prefabricated components, applied in manufacturing tools, ceramic molding machines, clay preparation devices, etc., can solve problems such as wood molds being easily deformed by moisture, endangering the service life of components, and affecting the landscape along the road, so as to promote construction. production levels, reducing construction costs, eliminating the effects of low overall skill levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

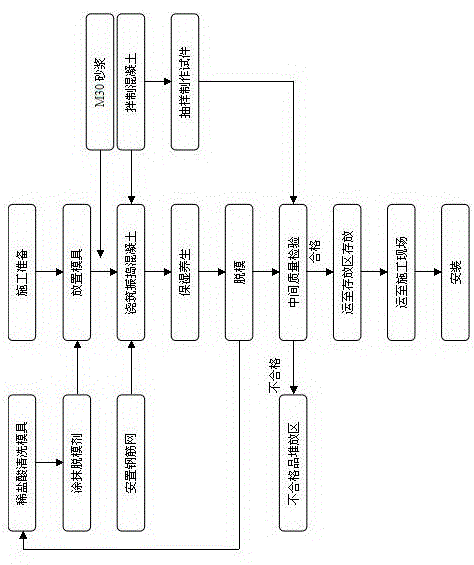

[0040] A factory-like construction process for small prefabricated components, which is characterized in that small components are prefabricated on a fixed site, using a shaped formwork made of high-strength composite plastics, and prefabricated through concrete mixing, pouring, vibrating, curing, and demoulding processes. For the small components required by the standard project, first select high-strength plastic shaping molds, which are made of a composite material formed by processing polypropylene, ABS plastic and some additives. According to the size of the small components, the master mold is first developed. The mold is then stamped from the master mold at one time, with a wall thickness of 4.5mm;

[0041] Specific steps are as follows:

[0042] (1) Use advanced CAD / CAM / CAE software and advanced CNC machine tools for mold manufacturing, and use special materials and heat treatment processes for mold cavities and cores to better guarantee mold accuracy, quality, and lif...

Embodiment 2

[0053] According to the process principle of the small-scale prefabricated component factory construction process described in Example 1, the prefabricated production of small-scale highway components is a new production organization model that construction companies can learn from other industries that can be mass-produced, process-based operations, and standardized management. It is one of the important means to achieve project standard management. Small components are prefabricated on a fixed site, using a shaped formwork made of high-strength composite plastics, through concrete mixing, pouring, vibration, curing, Demoulding and other processes to prefabricate small components required for standard projects.

[0054] Specific operation points:

[0055] 1. Construction preparation

[0056] (1) Overall layout: prefabricated parts processing area, vibrating area, semi-finished product maintenance area and finished product display area are set up in the site;

[0057] (2) Te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com