Management system for digital welding workshop

A workshop management and welding technology, applied in data processing applications, manufacturing computing systems, welding equipment, etc., can solve problems such as no intuitive assessment of weld quality, low level of digitization, weld defect monitoring, etc., to avoid unintended consequences. The effect of standardizing operations, avoiding delays in the construction period, and standardizing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

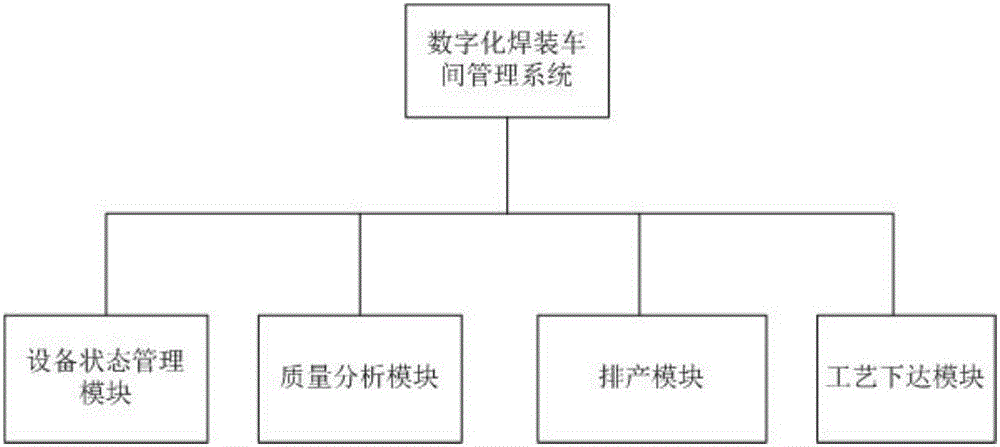

[0020] Such as figure 1 As shown, the digital welding workshop management system of the present invention includes an equipment status management module, a quality analysis module, a production scheduling module, and a process delivery module, wherein:

[0021] (1) The quality analysis module analyzes the stability of the weld and monitors the defects of the weld; the quality analysis module includes a weld stability analysis module and a weld defect monitoring module, wherein the weld stability analysis module will perform a fixed period of time The quality of the weld seam is evaluated as stable, general, and unstable. By calculating the variance of the current and analyzing the fluctuation of the current, it is used as the basis for evaluating the quality of the weld seam; An alarm is provided for fusion welding defects. When the current and voltage value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com