Yellow-resistance and rapid-curing stone material repair surface glue, preparation method and use method thereof

A rapid curing and anti-yellowing technology, applied in the field of material science, can solve the problems of poor permeability and yellowing resistance, environmental performance, poor yellowing resistance, and unsatisfactory yellowing resistance, etc., to achieve adhesion and Good permeability, good yellowing resistance, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

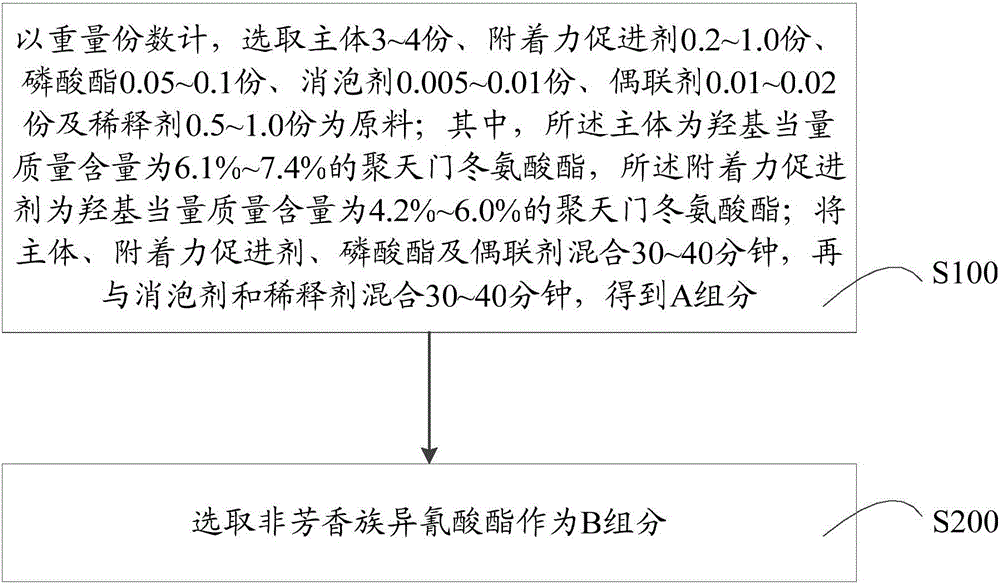

[0043] The preparation step S100 of component A includes: in parts by weight, select 3-4 parts of main body, 0.2-1.0 part of adhesion promoter, 0.05-0.1 part of phosphate ester, 0.005-0.01 part of defoaming agent, and 0.01 part of coupling agent. ~ 0.02 parts and 0.5 ~ 1.0 parts of diluent are raw materials; wherein, the main body is polyaspartic acid ester with a hydroxyl equivalent mass content of 6.1% ~ 7.4%, and the adhesion promoter is a hydroxyl equivalent mass content of 4.2% %~6.0% polyaspartic acid ester; mix the main body, adhesion promoter, phosphate ester and coupling agent for 30~40 minutes, then mix with defoamer and diluent for 30~40 minutes to obtain A component .

[0044] Specifically, the preparation temperature of component A is normal temperature.

[0045] The preparation step S200 of component B includes: selecting non-aromatic isocyanate as component B.

[0046] Specifically, the preparation temperature of component B is normal temperature.

[0047] Pr...

Embodiment 1

[0053] The anti-yellowing and fast-curing stone repair surface adhesive of Example 1 includes A component and B component.

[0054] In parts by weight, component A includes: 3.2 parts of main body, 0.8 part of adhesion promoter, 0.05 part of alkyl acrylate phosphate (1510 alkyl acrylate phosphate provided by Guangzhou Jingde Chemical Materials Co., Ltd.), dimethyl 0.005 part of base silicone oil, 0.01 part of KH-550 and 0.8 part of butyl acetate; wherein, the main body is polyaspartic acid ester (F420 polyaspartic acid ester provided by Zhuhai Feiyang Chemical Co., Ltd.) with a hydroxyl equivalent mass content of 6.1%. ester resin), the adhesion promoter is polyaspartic acid ester (F524 polyaspartic acid ester resin provided by Zhuhai Feiyang Chemical Co., Ltd. provided by Zhuhai Feiyang Chemical Co., Ltd.) with a hydroxyl equivalent mass content of 5.1%;

[0055] In parts by weight, component B consists of 3 parts of HDI trimer and 3 parts of HDI dimer.

[0056] The preparat...

Embodiment 2

[0061] The anti-yellowing and fast-curing stone repair surface adhesive of Example 2 includes A component and B component.

[0062] In parts by weight, component A includes: 3.5 parts of main body, 0.5 part of adhesion promoter, 0.05 part of alkyl acrylate phosphate, 0.005 part of simethicone, 0.02 part of KH-550 and 1.0 part of dimethyl carbonate; Wherein, the main body is polyaspartic acid ester (F220 polyaspartic acid ester resin provided by Zhuhai Feiyang Chemical Co., Ltd.) with a hydroxyl equivalent mass content of 7.4%, and the adhesion promoter is a polyaspartic acid ester with a hydroxyl equivalent mass content of 5.8%. Polyaspartic acid ester (the F520 polyaspartic ester resin provided by Zhuhai Feiyang Chemical Co., Ltd.);

[0063] In parts by weight, component B consists of 5 parts of HDI trimer and 2 parts of HDI dimer.

[0064] The preparation method of the anti-yellowing and fast-curing stone repair surface adhesive includes the preparation steps of component A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com