Array-type adjustable cage-type PCB inductor

An array type, PCB board technology, applied in the field of array type adjustable cage type PCB inductance, can solve the problems of different output cable lengths, affecting circuit indicators, hot, etc., to achieve good heat transfer effect and wide adjustable range , the effect of accurate value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

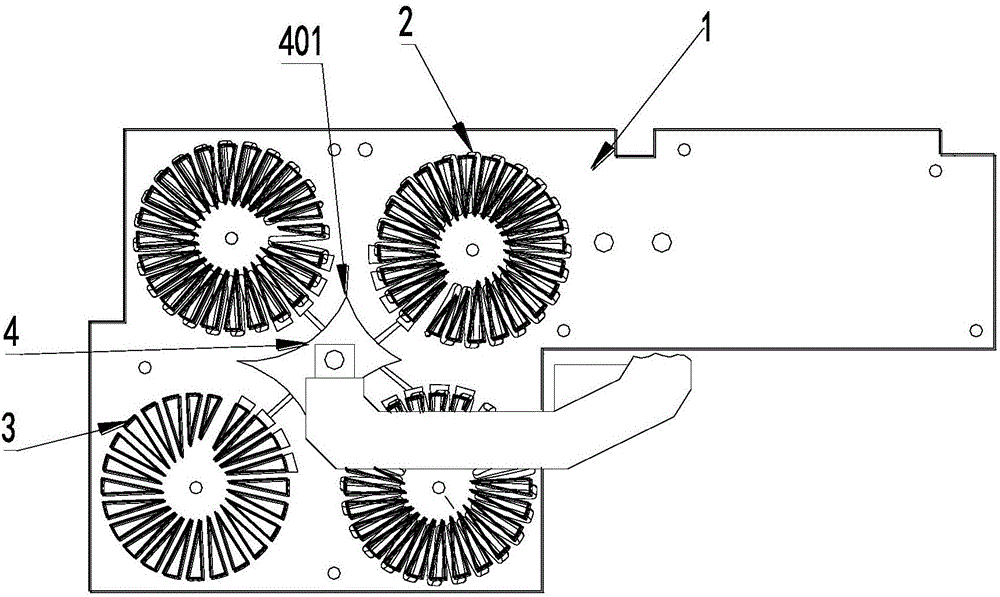

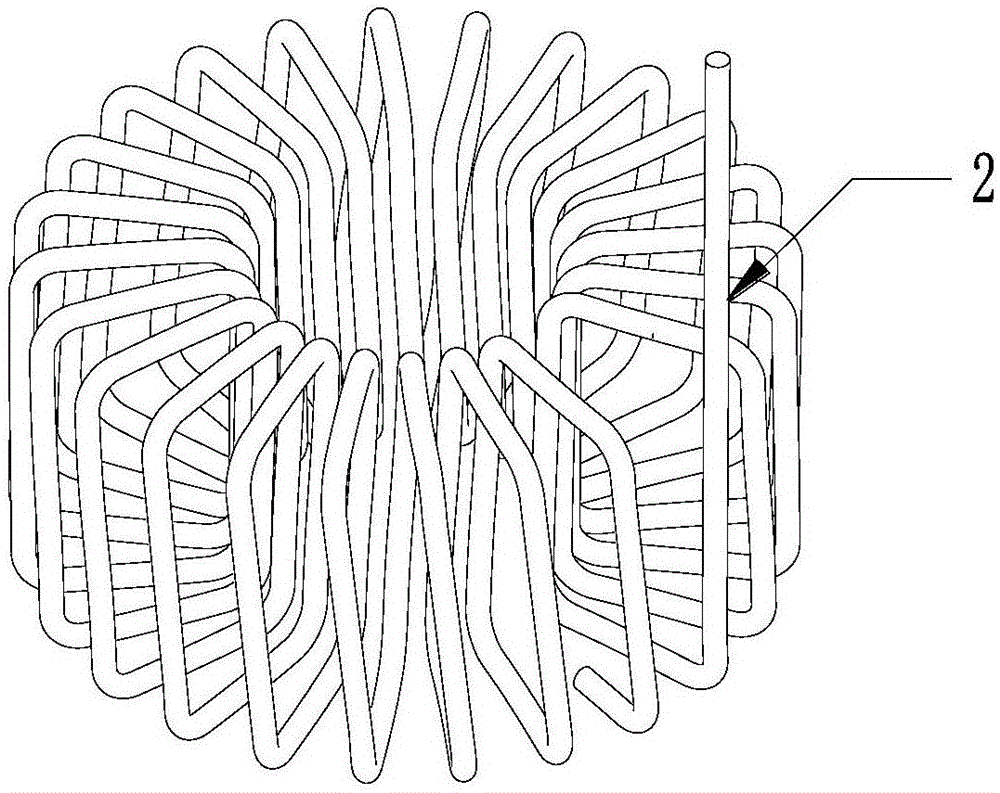

[0023] Such as figure 1 , 2 As shown, an array-type adjustable cage-type PCB inductor includes a PCB board 1 made of polyimide material that is resistant to high temperature and conducive to heat conduction. There are four cage-shaped rings arranged in a matrix on the PCB board 1. Coil 2, the cross section of the ring body of the cage ring coil 2 is rectangular or trapezoidal. The cage coil solves the problem of the close connection between the turns of the coil, so that there is a gap between the turns, which is good for heat dissipation.

[0024] The connection between the plate 1 and the cage-type toroidal coil 2 is respectively provided with a triangular strip pad 3, and the triangular strip pads 3 and each turn of the coil are respectively passed in the same number and position correspondingly, forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com