Double-outlet decorative cover and car

A technology with double outlets and decorative covers, applied in the direction of mufflers, exhaust devices, engine components, etc., can solve the problems of unbalanced distribution of gas, heavy exhaust system weight, uneven distribution of airflow, etc., to avoid appearance color differences and Effects of Airflow Noise Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

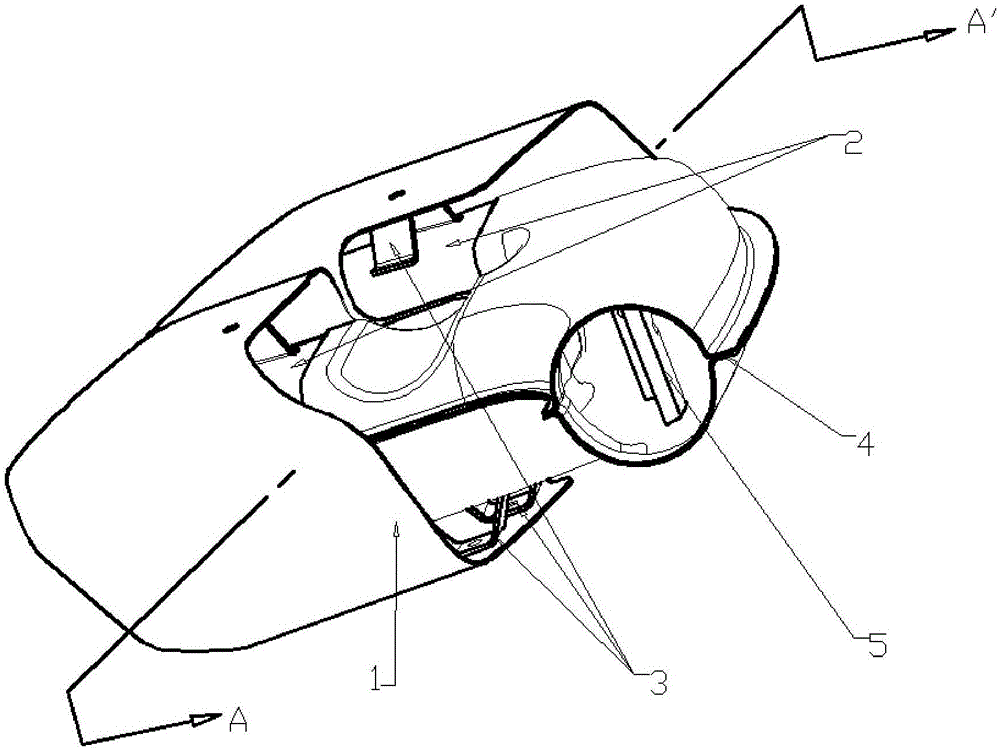

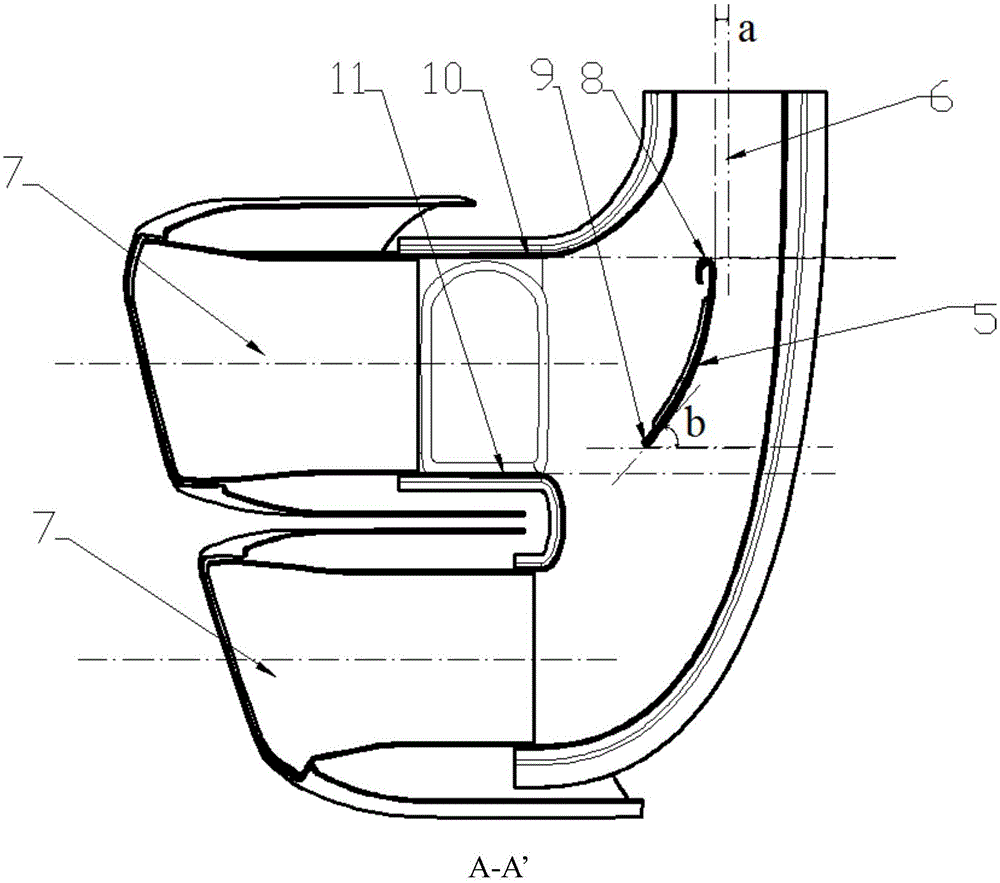

[0038] Using CATIA software to simulate and establish a figure 1 and figure 2 The double outlet decorative cover model of the structure shown, and specifically, the double outlet device cover includes a three-way exhaust pipe, the three-way exhaust pipe includes an inlet pipe section and two outlet pipe sections, and the two outlet pipe sections The central axes are parallel to each other, the central axis of the inlet pipe section and the axes of the two outlet pipe sections are perpendicular to each other and in the same plane, the inlet pipe section and the outlet pipe section are smoothly connected, and the three-way exhaust pipe is set There is a deflector, and the deflector has the following characteristics: the angle a between the tangent at the inlet end and the central axis of the inlet pipe section is 0°, and the angle a between the tangent at the outlet end and the central axis of the outlet pipe section is The angle b from the outside of the outlet pipe section t...

Embodiment 2

[0041] Using CATIA software to simulate and establish a figure 1 and figure 2 The double outlet decorative cover model of the structure shown, and specifically, the double outlet device cover includes a three-way exhaust pipe, the three-way exhaust pipe includes an inlet pipe section and two outlet pipe sections, and the two outlet pipe sections The central axes are parallel to each other, the central axis of the inlet pipe section and the axes of the two outlet pipe sections are perpendicular to each other and in the same plane, the inlet pipe section and the outlet pipe section are smoothly connected, and the three-way exhaust pipe is set There is a deflector, and the deflector has the following characteristics: the angle a between the tangent at the inlet end and the central axis of the inlet pipe section is 0°, and the angle a between the tangent at the outlet end and the central axis of the outlet pipe section is The angle b from the outside of the outlet pipe section t...

Embodiment 3

[0044] Using CATIA software to simulate and establish a figure 1 and figure 2 The double outlet decorative cover model of the structure shown, and specifically, the double outlet device cover includes a three-way exhaust pipe, the three-way exhaust pipe includes an inlet pipe section and two outlet pipe sections, and the two outlet pipe sections The central axes are parallel to each other, the central axis of the inlet pipe section and the axes of the two outlet pipe sections are perpendicular to each other and in the same plane, the inlet pipe section and the outlet pipe section are smoothly connected, and the three-way exhaust pipe is set There is a deflector, and the deflector has the following characteristics: the angle a between the tangent at the inlet end and the central axis of the inlet pipe section is 0°, and the angle a between the tangent at the outlet end and the central axis of the outlet pipe section is The angle b from the outside of the outlet pipe section t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com