Polyamide monofilament, and production method and application thereof

A polyamide and polyamide resin technology, applied in the field of polyamide materials, can solve the problems of pollution and complex production process, and achieve the effects of good softness, low initial modulus and good lodging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

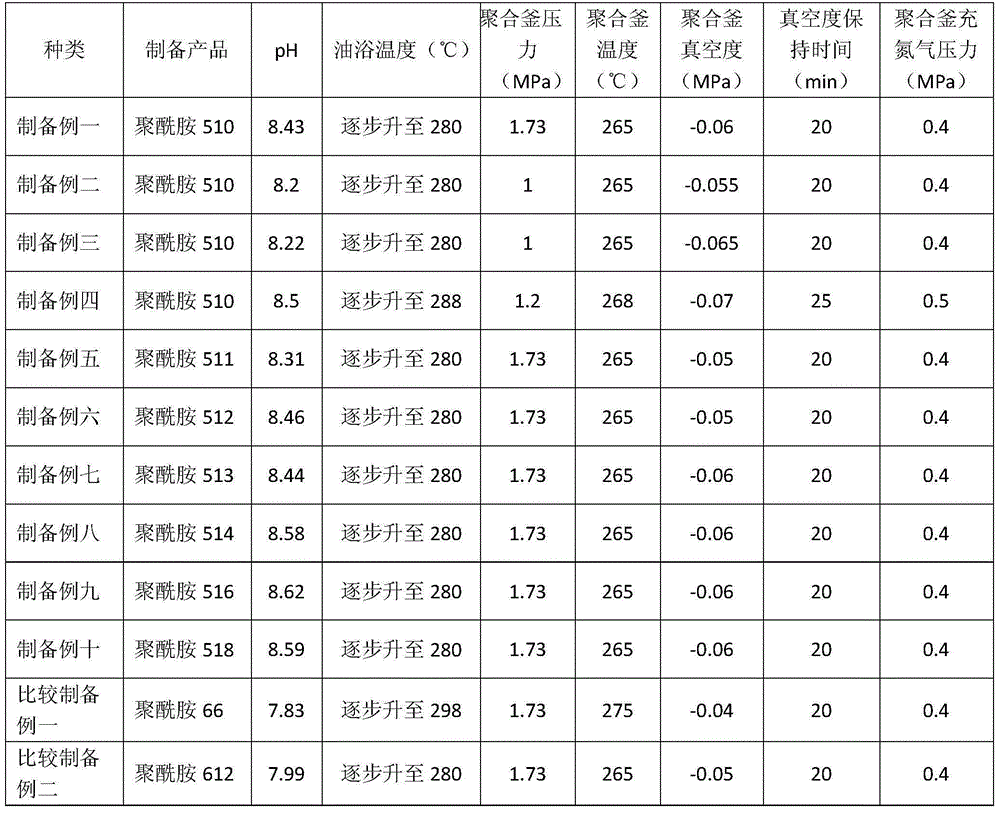

preparation example Construction

[0035] The invention relates to a polyamide resin and a preparation method thereof, a polyamide monofilament containing the polyamide resin, a preparation method and application of the polyamide monofilament, and a cleaning appliance using the polyamide monofilament.

[0036]

[0037] The production raw material of the polyamide resin of the present invention contains at least polyamide made of raw materials such as diamine and dibasic acid. However, according to specific circumstances, the raw materials for polyamide resin production can also contain additives, but it is necessary to ensure that the addition of polyamide is not less than 50% of the total weight of polyamide resin and the addition of additives does not exceed 50% of the total weight of polyamide resin. 50%, it can also be preferred that the amount of polyamide added is not less than 70% of the total weight of the polyamide resin and the amount of additives added is not more than 30% of the total weight of the...

preparation example 1

[0126] Preparation example one (polyamide 510)

[0127] This preparation example provides a kind of preparation method of polyamide 510, and it comprises the steps:

[0128] (1), replace the air with nitrogen in a 100-liter polymerization kettle (K / SY166-2007 type), add 30kg of pure water to the reactor, and then add 10.06kg (98.5mol) of 1,5-pentanediamine (including ASTM D6866 standard organic carbon from renewable sources), after stirring, add 19.93kg (98.5mol) sebacic acid, adjust the pH value to 8.43 with a small amount of 1,5‐pentamethylenediamine and sebacic acid (take nylon salt solution to dilute to 10% to detect the pH value) to obtain a nylon saline solution;

[0129] (2) Under a nitrogen environment, use an oil bath to heat, and gradually increase the temperature of the oil bath to 280°C. After the pressure in the polymerization kettle rises to 1.73Mpa, start exhausting. When the temperature in the kettle reaches 265°C, vacuumize to ‐0.06Mpa, keep the vacuum degre...

preparation example 2

[0131] Preparation example two (polyamide 510)

[0132] This preparation example provides a kind of preparation method of polyamide 510, and it comprises the steps:

[0133] (1), replace the air with nitrogen in a 100-liter polymerization kettle (K / SY166-2007 type), add 12.8kg of pure water to the reactor, and then add 10.06kg (98.5mol) of 1,5-pentanediamine (containing ASTM D6866 standard organic carbon from renewable sources), after stirring, add 19.93kg (98.5mol) sebacic acid, adjust the pH value to 8.20 with a small amount of 1,5‐pentamethylenediamine and sebacic acid (take nylon salt solution Dilute to 10% to detect pH value), make nylon saline solution;

[0134] (2) Under a nitrogen environment, use an oil bath to heat, and gradually increase the temperature of the oil bath to 280°C. After the pressure in the polymerization kettle rises to 1.0Mpa, start exhausting. When the temperature in the kettle reaches 265°C, vacuumize to ‐0.055Mpa, keep the vacuum for 20min, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com