Phenolic resin thermal insulation board and preparation method thereof

A phenolic resin and thermal insulation board technology, applied in the field of building thermal insulation materials, can solve the problems of poor toughness and low strength of thermal insulation boards, and achieve the effects of excellent thermal insulation performance, high fire performance and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

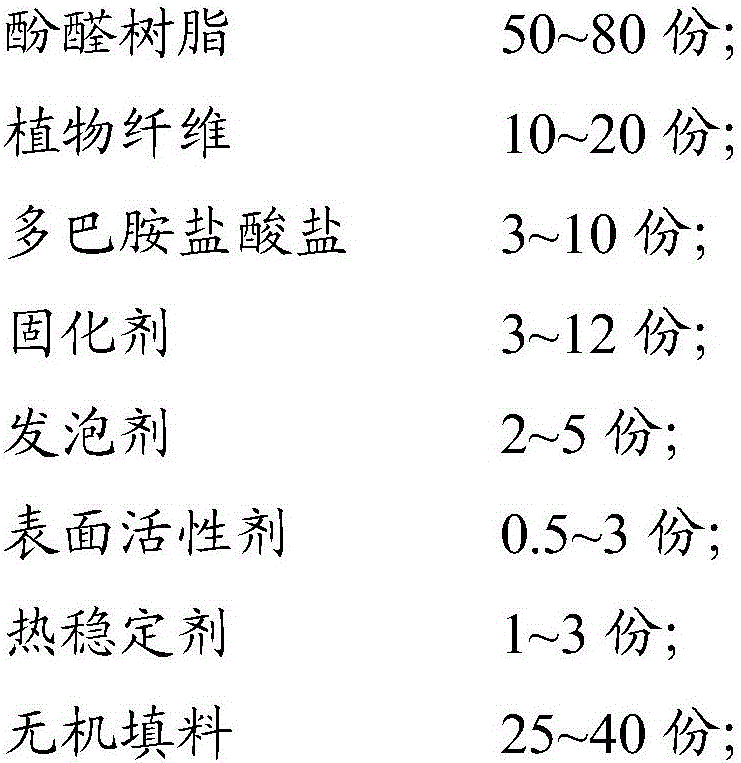

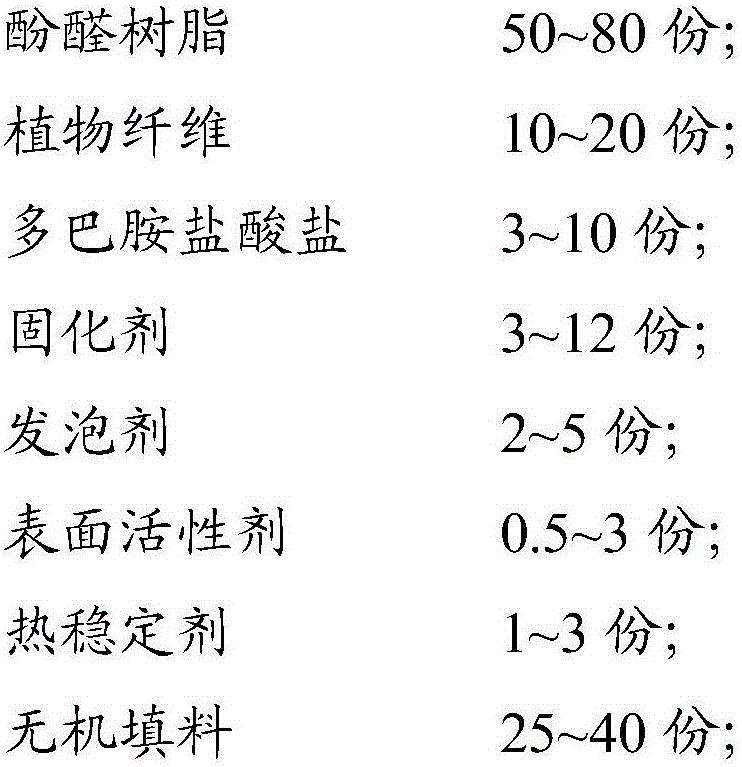

[0041] The present invention also provides a preparation method of phenolic resin insulation board, comprising the following steps:

[0042] Weigh the components of phenolic resin, plant fiber, dopamine hydrochloride, foaming agent, heat stabilizer, surfactant, and inorganic filler into the stirring tank, and stir evenly to obtain the mixture;

[0043] Then add a curing agent to the mixture, after foaming, curing and aging, the mold is released to obtain a phenolic resin insulation board.

[0044] Wherein, the phenolic resin, plant fiber, dopamine hydrochloride, foaming agent, heat stabilizer, surfactant, inorganic filler and curing agent are all the same as above, and will not be repeated here.

[0045] The preparation method of the above technology is simple and easy to operate, and the prepared phenolic resin insulation board has excellent compression resistance, heat preservation performance, strength and toughness.

[0046] In an embodiment of the present invention, the ...

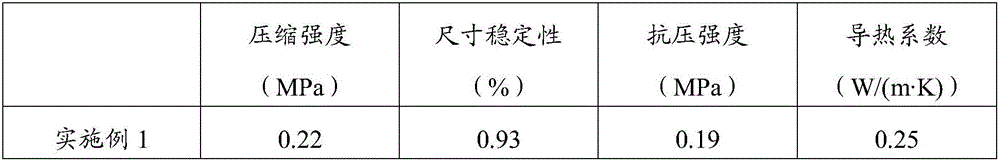

Embodiment 1

[0051] Add 25kg of hollow glass microspheres to 150kg of water, stir well and add 3kg of dopamine hydrochloride; after standing in the dark for 18 hours, add 50kg of phenolic resin, 10kg of corn stalk fiber, 2kg of n-pentane, 1kg of 2-(2' -Hydroxy-5'-methylphenyl) benzotriazole, 0.5kg sodium lauryl sulfate, after stirring, obtain compound;

[0052] Then add 3kg of tetrahydrophthalic anhydride to the mixture, and after foaming, curing, and aging, release the mold to obtain a phenolic resin insulation board.

[0053] The phenolic resin insulation board prepared in Example 1 has excellent thermal stability and can be used for a long time at 150°C.

Embodiment 2

[0055] Add 40kg of vitrified microspheres into 160kg of water, stir well and add 10kg of dopamine hydrochloride; after standing in the dark for 24 hours, add 80kg of phenolic resin, 10kg of rice husk fiber, 10kg of straw fiber, 5kg of n-heptane, 3kg of poly [(1-(β-ethyl)-2,2,6,6-tetramethyl-4-piperidinyl) succinic acid] ester, 3kg sodium lignosulfonate, stir to obtain the mixture;

[0056] Then add 12 kg of cyclopentetate dianhydride to the mixture, and release the mold after foaming, curing, and aging to obtain a phenolic resin insulation board.

[0057] The phenolic resin insulation board prepared in Example 2 has excellent thermal stability and can be used for a long time at 150°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com