Step-by-step pressure reducing deacidification and deamination method and system for coal chemical industry wastewater

A technology for coal chemical wastewater, deacidification and deamination, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sewage treatment, etc. Problems such as section operation and side line addition and subtraction are not easy to control, so as to increase the stable operation period, reduce mutual interference, and not easy to block.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

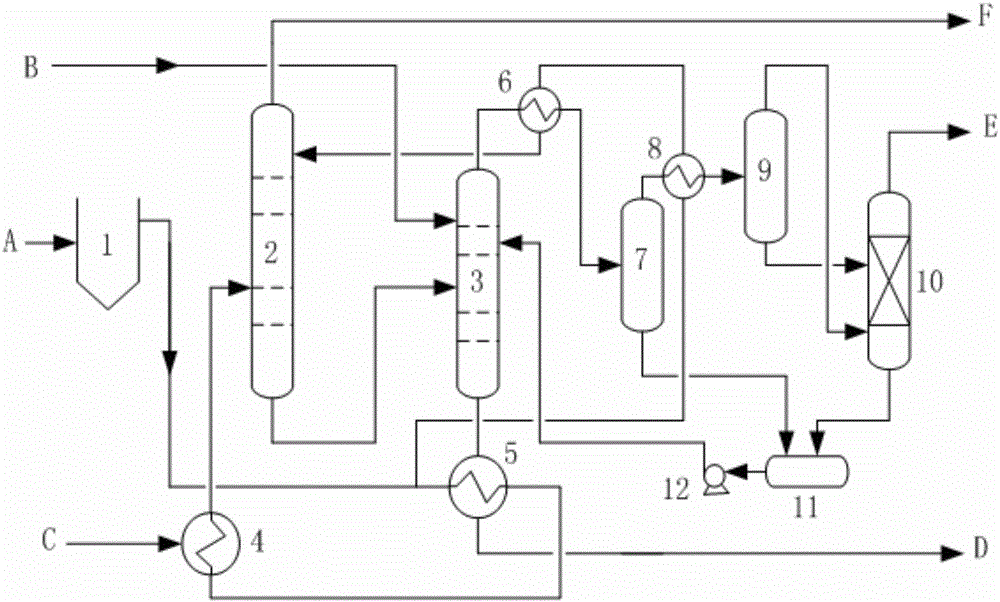

[0022] A method for deacidification and deamination of coal chemical industry waste water by step-by-step decompression double reactors and the equipment of the system include a settling tank (1), a deacidification reactor (2), a deamination reactor (3), and a waste water heater (4), waste water heat exchanger (5), primary cooler (6), primary flash tank (7), secondary cooler (8), primary flash tank (9), ammonia concentration reactor (10), separation liquid storage tank (11), return pump (12). The deacidification reactor, deamination reactor, and ammonia concentration reactor are all packing reactors, using honeycomb grid structured packing.

[0023] The process flow diagram of the present invention is as figure 1 shown. The waste water (A) containing volatile acid and ammonia nitrogen produced by the pressurized Lurgi gasifier first enters the settling tank (1) to remove insoluble impurities such as sludge and slick oil, and the CO in the waste water 2 Content 5000mg / L, H ...

example 2

[0026] The method and system for deacidification and deamination of coal chemical wastewater with double-reactor decompression step by step are as described in Example 1.

[0027] The wastewater generated during the pressurized fixed bed gasification process is subjected to gravity sedimentation to remove insoluble impurities such as sludge and slick oil, and the CO in the wastewater 2 Content 3000mg / L, H 2 The S content is 110mg / L, the free ammonia content is 5000mg / L, and the fixed ammonia content is 800mg / L. The wastewater treatment process and steps are as described in Example 1. Deacidification reactor The pressure at the top of the reactor is 0.35MPa, the temperature at the top of the reactor is 60°C, and the temperature at the bottom of the reactor is 140°C. Deamination Reactor Reactor top pressure 0.20MPa, reactor top temperature 90°C, reactor bottom temperature 120°C, other conditions as described in Example 1. After deacidification and deamination treatment by the...

example 3

[0029] The method and system for deacidification and deamination of coal chemical wastewater with double-reactor decompression step by step are as described in Example 1.

[0030] The wastewater generated during the coal coking process is subjected to gravity sedimentation to remove insoluble impurities such as sludge and slick oil, and the CO in the wastewater 2 Content 1000mg / L, H 2The S content is 50mg / L, the free ammonia content is 2000mg / L, and the fixed ammonia content is 500mg / L. The wastewater treatment process and steps are as described in Example 1. Deacidification reactor The pressure at the top of the reactor is 0.25MPa, the temperature at the top of the reactor is 60°C, and the temperature at the bottom of the reactor is 120°C. Deamination Reactor The pressure at the top of the reactor is 0.10 MPa, the temperature at the top of the reactor is 90° C., and the temperature at the bottom of the reactor is 110° C. Other conditions are as described in Example 1. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com