A positioning method of a servo drive with one-way positioning function

A servo drive, one-way positioning technology, applied in the direction of control using feedback, can solve the problem of insufficient positioning accuracy, and achieve the effect of eliminating backlash error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

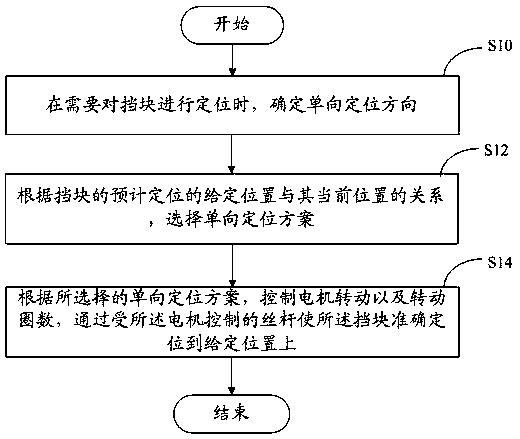

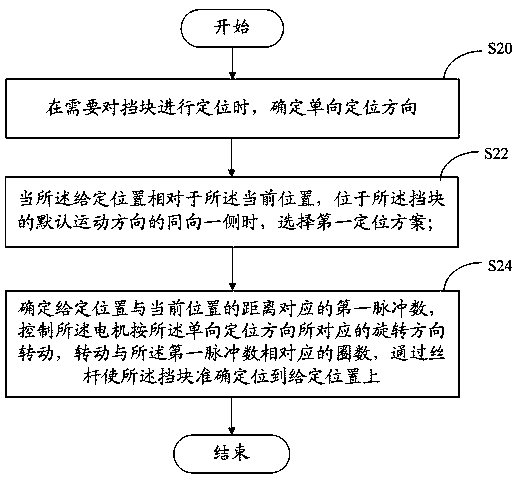

[0026] Such as figure 2 As shown, it is a schematic diagram of the main flow in an embodiment of the positioning method of the servo drive with unidirectional positioning function provided by the present invention; in this embodiment, the method mainly includes the following steps:

[0027] Step S10, when the stopper needs to be positioned, determine the one-way positioning direction, wherein each one-way positioning direction corresponds to one rotation direction of the motor, and each rotation direction of the motor corresponds to the stopper A default motion direction of ;

[0028] Step S12, selecting a one-way positioning scheme according to the relationship between the expected position of the block and its current position;

[0029] Step S14 , according to the selected one-way positioning scheme, control the rotation and number of rotations of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com