Scattering film and array substrate with same

A technology of scattering film and substrate, applied in the field of reflective display devices, can solve the problems of affecting the overall brightness of the display device, affecting the display viewing angle, reducing the light efficiency, etc., to achieve the effects of reducing reflection and scattering, improving light efficiency, and increasing overall brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

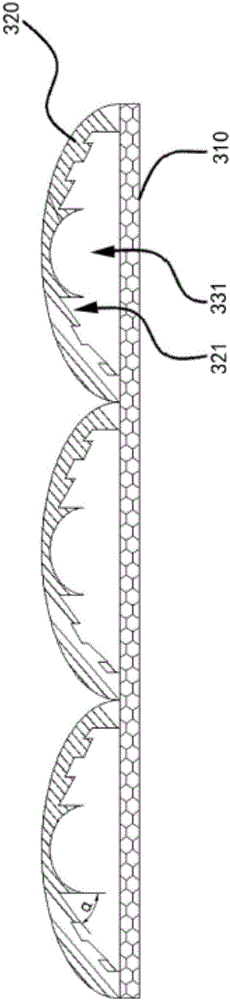

[0031] Refer to image 3 , image 3 Representatively shows a schematic structural diagram of a scattering film that can embody the principle of the present invention. In this exemplary embodiment, the scattering film proposed by the present invention is described using an array substrate applied to a reflective LCD display device as an example. It is easy for those skilled in the art to understand that, in order to apply the scattering film to other types of display devices, various modifications, additions, substitutions, deletions or other changes are made to the following specific embodiments, and these changes are still Within the scope of the principle of the scattering film proposed by the present invention.

[0032] Such as image 3 As shown, in this embodiment, the scattering film proposed by the present invention mainly includes a substrate 310 and a lens-like layer 320, and the material of the scattering film can be conventional PMMA acrylic or the like. Specifically, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com