Ground drilling and grouting treatment method for deep mining seam floor limestone water damage

A technology for drilling grouting and deep mining of coal seams, which is applied in directional drilling, earthwork drilling, wellbore/well components, etc. It can solve water inrush accidents, limited range of slurry diffusion, and difficulty in ensuring large cracks are filled and other problems, to achieve the effect of preventing water inrush, improving strength and water-proof performance, and having a large range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

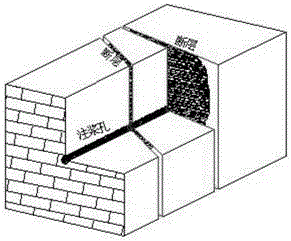

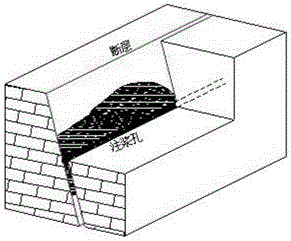

[0022] The present invention relates to a ground drilling and grouting control method for limestone water damage on the floor of deep mining coal seams, which comprises vertical drilling on the ground to form a vertical section of the drilling hole, and the vertical section of the drilling hole to the vertical section of the drilling along the bedding and then along the bedding. The bedding section of the borehole in the axial cracks of faults and folds, where the bedding section of the borehole is perpendicular to the maximum horizontal principal stress, and the suspected water outlet point of the limestone on the coal seam floor is filled by drilling grouting; the bedding section of the borehole is set in the middle of the three ash , so that the bedding near-horizontal boreholes are in contact with more interlayer structural surfaces; the boreholes also have multiple branch holes, which vertically intersect with the axis traces of faults and folds and pass through faults and ...

Embodiment 2

[0026] figure 1 , figure 2 Respectively, a schematic diagram of a ground drilling and grouting treatment method for deep mining coal seam floor limestone water damage of the present invention; a ground drilling and grouting treatment method for deep mining coal seam floor limestone water damage of the present invention as shown in the figure , the drill hole penetrated the fault, and the slurry spread along the fault for a distance of 60m.

Embodiment 3

[0028] The slurry pressure is 8MPa, and the slurry diffusion radius along the layer is 35m.

[0029] When the grouting pressure reaches 8-10MPa, the diffusion distance can reach 100-150m; the diffusion radius of low grouting pressure grout is small, and when the grouting pressure reaches 10MPa, the diffusion radius is about 50m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com